drawing process sheet metal Sheet metal drawing is the process of shaping flat metal sheets into three . Standard electrical box screws typically have a diameter of #6 (3.5mm) or #8 (4mm). For smaller junction boxes, #6 screws with a length of 0.75 to 1 inch (19 to 25mm) are commonly used. However, for larger junction boxes, you may need to use #8 screws or even longer screws to ensure a secure fit.

0 · simple sheet metal drawings

1 · sheet metal forming drawing

2 · sheet metal diagram fabrication

3 · sheet metal deep drawing calculations

4 · sheet metal basic drawing

5 · metal spinning vs deep drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

What can I make and sell with a CNC machine? You can sell kitchen tools like cutting boards and wooden utensils, décor like coasters, wall art, and shelving, plus a whole lot more. Review the list above for CNC project ideas.

A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.Sheet metal drawing is the process of shaping flat metal sheets into three . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels .

Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and .Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various . However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should .Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a .In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and prevent tearing during the drawing process. 2. Tooling: Punch: A solid piece that pushes the blank into the die cavity.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.

simple sheet metal drawings

sheet metal forming drawing

Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products.

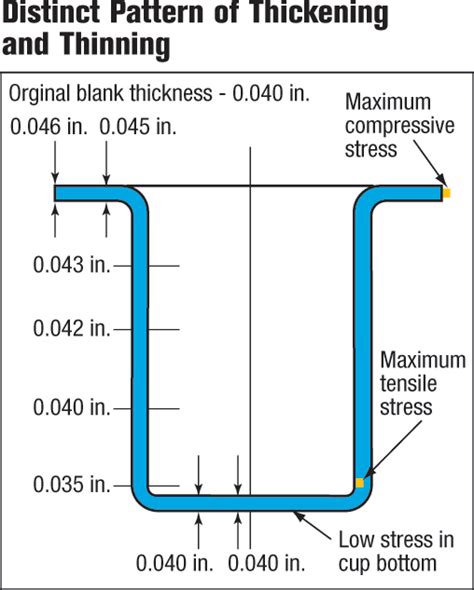

However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency. A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and prevent tearing during the drawing process. 2. Tooling: Punch: A solid piece that pushes the blank into the die cavity.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products.

However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.

sheet metal diagram fabrication

custom metal box factories

A junction box is an electrical box that allowed two or more electrical cables to be safely spliced together. A breaker box, or electrical service panel, is the large metal box that contains circuit breakers or fuses for the home's .

drawing process sheet metal|sheet metal deep drawing calculations