5 axis cnc machining parts Fit more stock on your machine table and watch your parts per cycle soar. Increase throughput, decrease tool change time, and reduce machine downtime. Learn More Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

the size of screws used in electrical boxes depends on the type of box and the gauge of the wire being used. For most applications, 10 screws are sufficient. However, if you are using thicker wire or a metal box, you may need to use 12 or 14 screws.

5-axis CNC machining is a suitable method for hook surface machining, unusual shape machining, hollow machining, oblique hole, etc. While 5-sided machining is similar to . 5-axis CNC machining allows you to make parts with complex designs while enjoying benefits such as easier machining operations, speed, and production efficiency. This article discussed the machining class, how it works, .Fit more stock on your machine table and watch your parts per cycle soar. Increase throughput, decrease tool change time, and reduce machine downtime. Learn MoreFANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.

There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the .5-Axis is best known for its ability to create complex parts, such as turbine blades, propellers, or orthopedic and knee implants. Before 5-axis, these parts were achieved by adding on fixtures or steps in the setup process. If your shop is . At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three .5-axis CNC machining excels in producing a wide range of complex and precise parts across various industries. If you’re tackling a high-difficulty project with demanding precision .

Owens’s CNC machinists and EDM micromachiners use state-of-the-art 5-axis micro-milling centers to achieve precision and accuracy, with .005 micron positional and 1° angular accuracies. This advanced technology streamlines . The rapid emergence of 5-axis machining ensures CNC precision machining of detailed and specific parts for energy equipment. These parts are machined to be durable and provide stability to workspaces. 5-axis CNC machining is a suitable method for hook surface machining, unusual shape machining, hollow machining, oblique hole, etc. While 5-sided machining is similar to but more capable than 3-axis machining.

5-axis CNC machining allows you to make parts with complex designs while enjoying benefits such as easier machining operations, speed, and production efficiency. This article discussed the machining class, how it works, and its applications.Fit more stock on your machine table and watch your parts per cycle soar. Increase throughput, decrease tool change time, and reduce machine downtime. Learn MoreFANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.

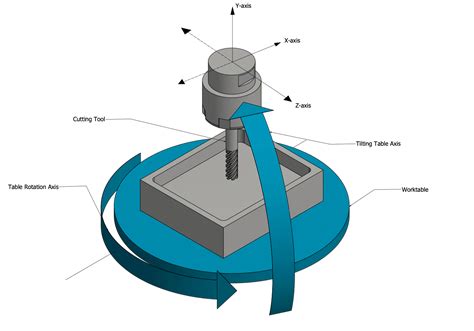

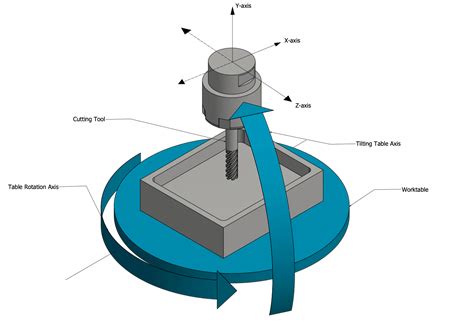

There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the machine’s head.5-Axis is best known for its ability to create complex parts, such as turbine blades, propellers, or orthopedic and knee implants. Before 5-axis, these parts were achieved by adding on fixtures or steps in the setup process. If your shop is currently using additional setups on your VMCs, you’re a strong candidate for a 5-axis machine. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.5-axis CNC machining excels in producing a wide range of complex and precise parts across various industries. If you’re tackling a high-difficulty project with demanding precision requirements, 5-axis CNC machining is your solution to .

what is 5 axis milling

Owens’s CNC machinists and EDM micromachiners use state-of-the-art 5-axis micro-milling centers to achieve precision and accuracy, with .005 micron positional and 1° angular accuracies. This advanced technology streamlines complex part production, reducing human involvement and ensuring repeatable accuracy. The rapid emergence of 5-axis machining ensures CNC precision machining of detailed and specific parts for energy equipment. These parts are machined to be durable and provide stability to workspaces. 5-axis CNC machining is a suitable method for hook surface machining, unusual shape machining, hollow machining, oblique hole, etc. While 5-sided machining is similar to but more capable than 3-axis machining. 5-axis CNC machining allows you to make parts with complex designs while enjoying benefits such as easier machining operations, speed, and production efficiency. This article discussed the machining class, how it works, and its applications.

Fit more stock on your machine table and watch your parts per cycle soar. Increase throughput, decrease tool change time, and reduce machine downtime. Learn More

FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.

There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the machine’s head.5-Axis is best known for its ability to create complex parts, such as turbine blades, propellers, or orthopedic and knee implants. Before 5-axis, these parts were achieved by adding on fixtures or steps in the setup process. If your shop is currently using additional setups on your VMCs, you’re a strong candidate for a 5-axis machine.

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.5-axis CNC machining excels in producing a wide range of complex and precise parts across various industries. If you’re tackling a high-difficulty project with demanding precision requirements, 5-axis CNC machining is your solution to .

metal pin in iphone 12 box

what does 5 axis mean

Automotive workers must use a variety of welding techniques on the auto’s body to conduct repairs, maintenance, and restoration. They work on fenders, frames, exhausts, automobile panels, and wheels composed of a variety of metals, all of which require experts to employ different types of welders.

5 axis cnc machining parts|what is 5 axis milling