cnc machine vibration CNC machine vibration problems can have a detrimental impact on productivity, accuracy, and surface finish quality. By understanding the causes and implementing the appropriate . Whether you're looking for an Ethernet Junction Box to combine both USB and Ethernet capabilities, or an ABS Junction Box that combines USB with other types of ports, AliExpress offers a vast array of options to suit your specific needs.

0 · vibration in milling tools

1 · vibration in milling machine

2 · vibration in machining

3 · lathe vibration optimization

4 · lathe vibration for machining

5 · lathe vibration and chatter

6 · chatter vibration in milling

7 · chatter vibration in machining

Learn why IT Pros trust StarTech.com for performance connectivity accessories.

CNC machine vibration problems can have a detrimental impact on productivity, accuracy, and surface finish quality. By understanding the causes and implementing the appropriate . Learn what chatter in machining is and how to defeat the vibration to improve your milling and lathe productivity in CNC.

This comprehensive guide delves into the complexities of vibration in CNC machines, exploring its causes, the detrimental impact it can have, and a range of practical .Vibration in CNC machines can occur due to various reasons. In this section, we will outline the key factors that contribute to CNC machine vibration. We will discuss the role of machine .Some practical steps can minimize or avoid the risk of vibration. Use all these steps to change the magnitude of or the direction in which the cutting forces act on the cutting tool. Use a cutting-edge angle close to 90°. Use a smaller nose . The chatter in machining, also known as vibration, refers to the vibration phenomenon in the cutting operation of machining processes such as CNC milling, turning, .

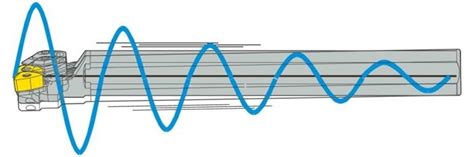

Machining vibration, also known as chatter, refers to the phenomenon of unwanted vibration generated during cutting operations in machining processes such as CNC milling, turning, and drilling, which .What is CNC machine vibration? Vibration is the unwanted behavior that occurs when machining parts. Vibration is the periodic movement of the tool and workpiece about each other.In this blog post, we will explore ten effective ways to reduce vibration in CNC machines. By implementing these techniques, you can enhance the performance, extend the lifespan of your .

Understanding Vibration in CNC Machines. Vibration is a mechanical phenomenon characterized by the oscillating movement of a machine or its components about an equilibrium point. In CNC machines, vibration can arise from various sources and manifest in different forms, each with its own set of consequences. Types of Vibration: The CNC machine tool’s spindle bearing vibration analysis has enabled timely detection of wear phenomena over time and local wear, unbalance in rotating, round-trip moving parts. How would you guys approach the challenge of reducing vibration in a benchtop CNC machine where you don't have the option of using 10 tons of iron? Vibration dampening materials are clearly available but they don't seem to be widely discussed here. 3. Enhance Machine and Workpiece Rigidity. Secure Clamping: Ensure that the workpiece is securely clamped. Any movement during drilling can initiate or worsen chatter. Machine Condition: Regular maintenance of the CNC machine is crucial. Loose components, such as spindle bearings or worn guideways, can exacerbate vibrations.

full-frame industrial high-speed CNC machine tools – one that is reliable, easy-to-operate and requires minimum maintenance. This requires adherence to strict design standards, . Machine Vibration and Chatter Machining vibrations are also referred to as chatter. Chatter is a self-excited vibration induced and maintained byWhen oscillations occur around an equilibrium point, they produce the mechanical phenomenon known as vibration. In the machining industry, vibration – typically

i've assembled most of machine, but can't get around this annoying problem z axis while moving downwards makes huge vibrations, while moving upwards - nothing so far i figured that pressing my hand against axis assembly removes vibration and loosening bearings on the end also helps x axis is assembled same as z, but it runs smoothly to get an idea how it . The vibration signal obtained during the initial cutting session when a fresh cutter was used for the first time served as a reference or baseline for comparing the vibration signal obtained from the machine. Differences in the pattern, amplitude, and frequency of vibration signal waves that may indicate wear and damage were observed. The vibration of CNC machine tools can usually be heard. An experienced mechanic will be able to recognize when chattering occurs through his unique voice. Usually 100μm is used as the criterion for judging whether the tremor is appropriate. If the vibration amplitude of cutting exceeds 100μm, it may cause the tool or workpiece to loosen, and . Machine tool vibrations play a significant role in hindering productivity during machining. The growing vibrations accelerate tool wear and chipping, cause a poor wave surface finish, and may damage the spindle bearing. Some research showed that tribological properties such as friction factors can have obvious influences on the topography of rough surfaces and .

Technically, the vibration sensors for CNC machines provide high-resolution vibration analysis, crucial for maintaining the precision and efficiency of CNC machines. Financially, the long-term cost savings from reduced maintenance and enhanced machine uptime make Trivibe sensors a valuable investment for modern manufacturing facilities reliant .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc Members Online • . Vibration Dampening for CNC . I often see people fill their CNC machines with sand in order to dampen and absorb vibration, as well as to increase weight. I had something similar in mind, but sand particles are too small and will .CNC Anti-Vibration Machine Mounts :Dynemech; La compresión cizalladura amortiguación de Vibraciones / Soportes; Knowledge Network. Vibration Engineering; Why Antivibration pads; Exhibitions; Topical; About Us; Quality; Enquiry; Contact Us; Search for: Levelling Mounts. Levelling Mounts dm_adm 2023-02-20T06:46:23+00:00.

problems with metal frame houses

This paper suggests an intelligent vibration-based condition and fault diagnostic technique for the identification of bearing faults in CNC machine. Investigational vibration data obtained for .

vibration in milling tools

Vibration is one of the most typical mistakes made during CNC turning. To put it simply, when the lathe vibrates, a regular cutting process is disrupted and harmed, resulting in a significant decrease in machined surface .

In this section, we provide an overview of the existing research and developments in the field of vibration monitoring for CNC machines. Vibration monitoring plays a pivotal role in ensuring the accuracy, reliability, and efficiency of CNC machining processes. Chatter affects the product quality significantly [9,10].CNC spindle vibration analysis refers to the process of examining and assessing vibrations in the spindles of CNC (Computer Numerical Control) machines. A spindle is a rotating component that holds and drives cutting tools or . NUM has launched an accelerometer-based active vibration control system for CNC machine tools. "Primarily designed to improve machining by virtually eliminating tool head vibration, the system further helps increase productivity by maximizing material removal rate (MRR) and can also provide valuable real-time feedback for predictive maintenance .

processing office distribution center po box 2905 kansas city ks

Displacement Tolerance: Not to exceed 0.100 MIL at max speed Note: For 15K spindles, at 8K and 15K CPM the spike must not be more than 0.100 MIL Note: For GR machines, the spike at the maximum spindle speed must not be more than 0.200 MIL Velocity Tolerances: Not to exceed a total of (3) spikes between 30k and 210k cpm that exceed 0.005 in/s.Mobile measuring case VMSet-05 - Machine diagnosis machine tools. Determination of damage and its extent while the machine is running; Vibration diagnosis on spindles and high-speed drives; Determination of natural frequency problems (e.g. "chatter marks") Diagnosis of rolling bearings; Field balancing in 1 and 2 planes; Checking the machine set-up My Humble Home-made CNC Machine Bottle Opener; accuracy of home made CNC machine; Linear Motors for a home made machine? Posted via Mobile Device . 04-03-2017, 10:51 AM #2. CNCMAN172. . On your vibration since you machine worked prior to the vibrations cutting the same materials, you should examine your ballscrews carefully. . 3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component .

CNC machining vibrations and chatter are unwanted phenomena that can affect the quality, accuracy, and productivity of your machining operations. They can also cause tool wear, noise, and damage .The frequency of ten vibration changes based on the tool size/ flute count rpm . For the best results you want the machine as solid as possible. I make custom guitars etc. you will be fighting the machine if it’s not as ridge ass possible and break small tools with the same feed rates etc as if it was bolted to floor.Buy anti vibration pads for heavy machinery for CNC, Power Presses, Lathe Machine, Forging Hammers and heavy industrial machinery. In this section, we provide an overview of the existing research and developments in the field of vibration monitoring for CNC machines. Vibration monitoring plays a pivotal role in ensuring the accuracy, reliability, and efficiency of CNC machining processes. Chatter affects the product quality significantly [9,10].

We have an older VMC with 2 speed gear box and belt drive to spindle. Machine has an obvious vibration but been running that way for years and not getting any worse. Leaves this specific pattern in the finish. I am curious if anyone has seen these cog belts actually cause vibration or just.

vibration in milling machine

RS-232 communication quality, especially with FANUC's implementation of xon/xoff, depends upon the FIFO depth of the RS-232 device's UART. In the case of USBRS-232 conversion, the RS-232 UART is embedded within the USB chip, so the FIFO is a feature of the USB chipset.

cnc machine vibration|vibration in milling machine