cnc machine validation format Quality testing and inspection in CNC machining are processes dedicated to verifying that the output meets specific standards of accuracy and integrity. These procedures encompass a range of activities, from dimensional . $2,800.00

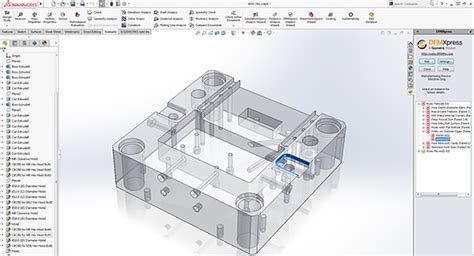

0 · solidworks cnc validation

1 · cnc quality testing and inspection

2 · cnc machining quality inspection

3 · cnc machining quality control

4 · cnc machining process control

5 · cnc machining process checklist

6 · cnc machining equipment specifications

7 · cnc finish inspection

In this Beadaholique video Kathleen demonstrates using metal punches to stamp letters into a metal blanks. She shares some nifty tips to get your letters lined up and spaced neatly.

In this blog post, we explored the importance of implementing a comprehensive CNC machine validation format to ensure the accuracy, reliability, and safety of these machines. By following the best practices and recommendations outlined in this article, manufacturers can optimize their .CNC machine validation is a systematic process of verifying and documenting .

Take an in-depth look at CNC machining, from milling to turning and prototyping to production. Our downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing . Quality testing and inspection in CNC machining are processes dedicated to verifying that the output meets specific standards of accuracy and integrity. These procedures encompass a range of activities, from dimensional .

OQ: - Verify that each components of the machine work: so verify that the control panel works, the tool bits can be change and spin. - Verify that safety doors, switch, alarm . CNC's must be validated. Typical IQ/OQ/PQ methodology does not need to apply to every custom program. IQ/OQ is what you need to do once and maybe some revalidation of .

Validation of Manufacturing Process. The First Article Inspection (FAI) verifies that the CNC machine programming and setup can produce a part that meets the design specifications. It essentially provides a proof of concept .CNC machine validation is a systematic process of verifying and documenting the performance, accuracy, and reliability of computer numerical control (CNC) machines. It involves rigorous .

3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command .

The World's leader in large format CNC routers and hotwire cutters. Every Autoscale CNC gantry router provides unprecedented cutting areas and travels at an excellent price and features a wide range of available options to customize .1. Understanding CNC Machine Validation:\ CNC machine validation is a systematic process of verifying and documenting the performance, accuracy, and reliability of computer numerical control (CNC) machines. It involves rigorous testing and inspection to ensure that the machines are operating within acceptable tolerances and meeting the desired . The best controls for CNC machining: 1) an X hi/lo-R control chart for every finish tool with control limits of approx. 75% of the tolerance (to start) 2) a sampling frequency of the number of parts it takes for the tool wear from the lower control limit to the upper control limit for an OD or outer length (opposite for ID or inner length .3 CNC machinist resume examples found. All examples are written by certified resume experts, and free for personal use. Copy any of the CNC machinist resume examples to your own resume, or use one of our free downloadable Word templates. We recommend using these CNC machinist resume examples as inspiration only, while creating your own resume.

CNC equipment, known for its precision, plays a crucial role in achieving this. Dimensional accuracy isn’t just a measure; it’s a testament to the quality and reliability of the machining process. Surface Finish and Roughness. Surface finish and roughness significantly impact the performance and aesthetic appeal of CNC machined parts. When .

metal boxes small candy

solidworks cnc validation

When will Autodesk Inventor have an option to export the more CNC machine file formats? It has been around for more than 8 years. My customer will only accept these file types for their machines. DSTV format is an industrial standard defined by the German Steel Construction Association. AKA .NC1 Thanks Seriously Lost In Outer Tekla Space! ; From prototype to production, DATRON Dynamics optimizes your entire machine workflow with touchscreen-enabled DATRON CNC machines. With headquarters located on the East Coast in Milford, New Hampshire, and an office in Livermore, California, we are your one-stop DATRON Partner in North America . This field is for validation purposes and .

Training: Unless a particular validation or operation within the validation of a process or piece of equipment requires specialized training, EMS relies on the existing skills and training of the employees used in the validation process. That is to say , if the validation requires an employee to run a part on a CNC machine, anIn this blog post, we explored the importance of implementing a comprehensive CNC machine validation format to ensure the accuracy, reliability, and safety of these machines. By following the best practices and recommendations outlined in this article, manufacturers can optimize their CNC machine operations and achieve higher quality outputs. Hi @Anonymous . Because boxzy.cps is a post processor that creates g-code from the CAM operations you will set up in Fusion 360, you cannot export a part file in that format from AutoCAD.This is because the NC file is not the part design, but rather the means of communication between the CAM operations set up in Fusion and the machine that the cuts .

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.

f.prd.11.Tool Life Monitoring 1 - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document is a tool life monitoring sheet used to track cutting inserts on a machine. It contains columns to record the date, part name and number, insert edge, initial and end part counts, production time, description of any insert changes .be documented during the in-house validation run 3-12 ALL equipment settings during the in-house validation run must be documented. (Including air pressures.) 3-13 Are machine detail prints available (with common designation of components) 3-14 Spare parts and a machine specific spare parts reference list must be readily available. (crib set-ups Dear All, I am interested in creating my own CNC wire bender. I would like to bend .09" to .055" piano wire and found this cool DIY project which would be able to output 3D Wires. Before embarking on trying to build this project I see that inputting the dimensions for the wire I am looking for may be troublesome. Is there a format I can export from fusion 360(like stl) to .

Validation of Manufacturing Process; The First Article Inspection (FAI) verifies that the CNC machine programming and setup can produce a part that meets the design specifications. It essentially provides a proof of concept .Synchronized the training of operators on new CNC equipment and programs and aided in outlining jigs, tools and special equipments for CNC applications. CNC Application Engineer, May 2000 – July 2005. Cybercoders, Leaburg, OR. Handled customer machine set-up and programming for Swiss CNC Machine Tools. Established machine programming procedures.

This typically involves a validation plan, programming for CNC and quality equipment, initial dimensional and visual checks, and any documentation such as pFEMA, REACh, etc. needed. IQ (Installation Qualification) Examples- Machine set up and installation is key for manufacturing equipment to deliver a desirable result.

This document summarizes a machine shop's production report for one shift on February 25, 2022. It lists 6 jobs completed on a CNC machine including the production of nut stoppers, tailstock clamping pads, an SPM job boring, and level guage plates. It reports the total cycle time, production hours, quantities produced, rework materials and rejection quantities for each job. . The difficult part for me is to know how to make the excel file send the program from computer to the CNC machine. I want that the operator does not need to search for the program or to go throgh different softwares, just an excel sheet in front of him and raw material which he loads in the chuck and clicks on the file. . Save your Excell .

cnc quality testing and inspection

Operator can rejust program to make different product, diffenrent product,different progam, so before lot production, you need to validate the program( also you can call it automated process software), so do not confuse it with the CNC machine's own software. About validation methods, you can see the software validation guidance of FDA .When there is a sharp noise in the CNC machine, the worker will stop the machine and take out the tool and observe the breakage under a high-precision electron microscope. . investigation, G.L. and Y.F.; writing—original draft preparation, G.L. and Y.F.; validation D.C.; writing—review and editing, L.S.; supervision, J.Z. All authors read . Thank you for the assistance, I appreciate it! Another question that I have (still plugging away at all my notes here) is in regards to as9100d 7.1.3 - Infrastructure. The auditor noted that while we have preventative maintenance for our CNC machines, we are lacking on the other items in our shop, and noted back to 7.1.3.

the machine is PVC tube cutting machine that produce tubing for medical device. it uses encoder to control the length of tube. Yesterday, our validation compliance advised to perform re-validation for the relocation however not clearly stated in the ISO 13845 in which condition to perform re-validation due to relocation. *) Process validation is per process. I recommend - in the context of process validation - that you focus on those machine runs that are serial production of significant counts (i.e. >100). - The DMR should contain everything that is required for making a conforming device; regardless of who designed it, or is regulatorily responsible.The material in this manual was checked and deemed to be accurate. The entire risk as to its accuracy and quality is with the reader. In no event shall NexGen Manufacturing Systems, Inc. be liable for direct, indirect, or consequential damages resulting from any Machine Setup: The appropriate material is loaded into the CNC machine, tools are calibrated, and the machine is set up based on specifications from the CAM software. Production: The CNC machine reads the G-code and starts creating the physical part, milling, drilling, turning, or otherwise shaping the material based on the design’s directives.

metal bracket for exhaust fans

Find many great new & used options and get the best deals for Skechers Metal lunch box 2002 RARE at the best online prices at eBay!

cnc machine validation format|cnc machining equipment specifications