grounding cnc machines In this article, we will explore the effects of improper CNC router grounding and common machine grounding issues, aiming to provide you with strategies for proper grounding . As a worldwide leading manufacturer of machine tools, the integrated technology and automation solutions of DMG MORI cover turning and milling machines, as well as ULTRASONIC, LASERTEC and ADDITIVE MANUFACTURING.

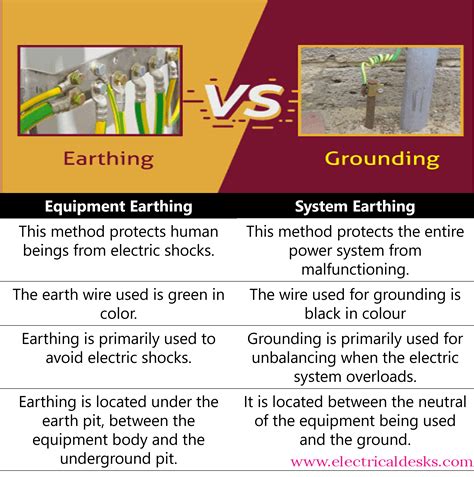

0 · system grounding vs equipment

1 · proper grounding of electrical equipment

2 · personal grounding equipment

3 · how to properly ground equipment

4 · grounding techniques for electrical equipment

5 · grounding of electrical equipment

6 · earth ground vs equipment

7 · clint ober official website

According to the Wikipedia article on the .50 BMG, it is capable of penetrating 22.2 mm of steel at 100 yards. Dividing this thickness by a bit less than 7 due to our increase in surface area, we get a rough estimate of being capable of punching through about 3.25 mm of steel.

The most important thing is to HAVE a ground, and only one. The body of the machine should be securely bonded, through a dedicated wire, to the power ground of your . This is a complete breakdown of the importance of shielding, and grounding your CNC for optimal performance. The methods covered will produce a machine with .

Machine grounding encompasses the connections between the table bed, plasma, mechanics, star ground, and ground rod. These are installed to give electrical noise (EMF) induced by the plasma system a path to drain away . In this article, we will explore the effects of improper CNC router grounding and common machine grounding issues, aiming to provide you with strategies for proper grounding . Learn about CNC electrical noise, grounding techniques, and interference filters to improve your CNC machine's performance. Get expert tips on CNCCookbook! Specifically, adding a local ground rod at the CNC can clean up the electrical system "noise" and will help the machine run better unless you happen to get a nearby .

system grounding vs equipment

Good practices for installation, powering and grounding, and maintenance procedures are all required to prevent malfunction, degradation, and damage to electronics. . of service and equipment grounding. The basic design of CNC machines is also explained. Based on a survey of several CNC machine representatives, the paper will explore .Two separate ground schemes should be used—a machine ground and a control ground. This will protect the more sensitive control electronics from the plasma system.

custom electric metal box quotes

This is the first part of a four part series covering an in depth overview of the best practices for implementing proper EMI protection, and grounding proces.How to Ground a CNC Plasma Table. The EMI and RFI noise interferences can happen due to the information and power passing through the wires or the plasma cutting machine.. You may find yourself using the electrical grounding that . Grounding your Shapeoko - CNC Machines / Shapeoko - Carbide 3D Community Site. 4 Likes. Brew (Steven Middleton) July 25, 2023, 2:57am 7. Thanks for the link. Awesome stuff. system (system) Closed August 23, 2023, 4:27pm 8. This topic was automatically closed after 30 days. New replies are no longer allowed. . Alert the OEM of possible shock hazards, lightning damage, ground loop currents, and electrolysis in your facility. If you find its "required" ground rod causes such problems, ask the OEM to accept liability in writing. One of the most hotly debated subjects in the fields of power quality, the NEC, and grounding today is CNC machine tool grounding.

proper grounding of electrical equipment

This tutorial video covers using the proper "Star Point" grounding process with your CNC automation controller.If you have an questions, or require a quote p.The design and manufacture of grounding cnc machines comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards. CNC machining of precision parts, workpiece clamping can complete drilling,reaming,tapping,milling Various processes such as .earth ground. Requirements: 1. Have a certified electrician verify the grounding before running the machine. 2. 3 ohms of resistance or less from the ground rod to the earth. 3. The ground rod must be independent and dedicated to the N machine only. 4. The ground rod must be at least ½” in diameter and made of copper, steel copper

This video covers my new grounding solutions to make your CNC as safe, and bulletproof as possible. These components are offered in complete packages to make. Specifically, adding a local ground rod at the CNC can clean up the electrical system "noise" and will help the machine run better unless you happen to get a nearby lightning strike that can cause induced voltage to travel through the delicate circuitry, causing failure.

With enough foil and grounding, you can shield anything from electrical noise: Some Methods to reduce electric noise in your CNC controller and components : Using Opto-Isolated breakout board and PC power; Using shielded cable (specially for motor encoder and sensors) Wiring all sensors and switches N.C (normally closed) Avoiding grounding loops CNC Grounding - Jeff Holmes - Hanging By The Moments This is a short video giving a simple example of star grounding. I hope this helps some people with grou.

CNC Electrical Noise Problems: Grounding Techniques & Interference Filters After backlash, the second biggest source of frustration seems to be electrical noise problems on home brew CNC systems. Noise can manifest itself in a variety of ways including uncommanded movements, servo encoder problems, and limit switches tripping unexpectedly.

Grounding of your CNC machine is very important, for safety reasons and enhanced reliability. Unfortunately, most kits on the market completely ignore grounding of the machine. This can create safety hazards and intermittent interruption of machine operation due to static buildup and electrical noise.

CNC machines across the world, these problems have become a significant financial concern to many CNC machine users and their electric utility companies. This paper begins with a brief explanation of the fundamentals of service and equipment grounding. The basic design of CNC machines is also explained. Based on a survey of several CNC

If you are grounding a machine at a dedicated rod at the machine, are you also connecting to the distribution/service panel? . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest .I attempted numerous solutions to address the problem, including disconnecting the spindle power cable from the drag chain, grounding the vacuum system, grounding the vacuum hose, grounding the PC, and grounding the CNC machine. I also invested in a USB isolator, but unfortunately, none of these measures proved effective. In any industrial setup, proper grounding is a prerequisite for ensuring the safe and reliable operation of equipment, including CNC routers. Grounding provides a secure path for electrical current to dissipate, protecting both the machine and its operators from potential harm. 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In .

custom fabrication metal

Computer numerical control (CNC) machines are used to shape metal parts by milling, boring, cutting, drilling, and grinding. A CNC machine generally consists of a computer-controlled servo-amplifier, servo-motors, spindle motor, and various tooling. The machine can be programmed to shape a part by use of a front control panel. More sophisticated models allow . I use this building for my shop, 3 cnc machines, 350 amp mig welder, 275 amp tig welder. I currently run a phase perfect but will be converting all machines to single phase. The building is 30' x 50' with a 15' peak. . machine grounding and bonding. I wanted to find some more information to share on the subject, in addition to the information .

An earth ground on a cnc machine should not be confused with the electrical safety ground, and under most conditions should be an entirely separate grounding systems from the green grounding wires that go back to your electrical panel. I have a suggested earth grounding document that has been used for years with success for plasma cutting .

Computer numerical control (CNC) machines are used to shape metal parts by milling, boring, cutting, drilling and grinding. A CNC machine generally consists of a computer-controlled servo-amplifier, servo-motors, spindle motor and various tooling. The machine can be programmed to shape a part by use of a front control panel. More sophisticated models allow . Potential pitfalls Some CNC machine manufacturers recommend, or even require, the addition of a supplemental ground rod at the CNC machine. (See sidebar “Manufacturers Speak Out About Machine Grounding and Ground Rods,” below.) In most cases, this is an 8-ft copper rod driven next to the machine, often through the concrete floor, and bonded . How to properly ground your Shapeoko CNC machine to help avoid static related problems with dust and chips sticking to the rails or controller disconnects wi.

personal grounding equipment

Hi I am reworking my control box for a 3 axis cnc machine. It seems emi or noise can be a major problem for reliable machine performance. I`m confused between the grounding of the 115 VAC and the various dc power supplies. Its my guess that anything that has shielded wires goes to a separate grounding location from the AC buss bar. From my reading this is . Putting an industrial plasma..such as a Hypertherm high definition system on any CNC machine that uses an office computer for the cnc control..can and will cause issues that will require earth grounding, isolation of input power, grounding and shielding of all control cables as well as isolation of the plasma system leads from the computer .

CNC Machining . Grounding machines? Thread starter dabigguy; Start date Oct 21, 2016; Replies 80 Views 17,391 Prev. 1; 2; 3 . So the machine ground wire really just protects from a transformer failure of some sort I would assume. S. SeymourDumore Diamond. Joined Aug 2, 2005 Location CT. Dec 2, 2022

custom cnc turned parts

custom fabricated metals fontana

Our wooden shelves with brackets can be installed onto any wall in your home, including plasterboard walls. We've sourced handcrafted metal shelf brackets and chosen a wide range of styles, from industrial shelf brackets, Read more. rustic brackets contemporary brackets and traditional brackets.

grounding cnc machines|earth ground vs equipment