3 axis cnc milling machine system Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table . Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

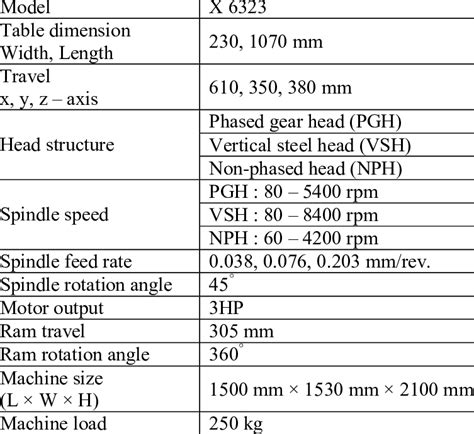

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

Welding galvanized steel is now a topic we can explore in depth. We’ve covered everything from preparing your material, choosing the correct techniques, troubleshooting issues, and adding those finishing touches.

specifications of cnc milling machine

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table .

small 3 axis cnc mill

Super-wide slideways (X- / Y-axis) to minimize quadrant projection; High .Z-axis drop prevention function, ideal for blackouts; Oil cooler (separate type) .

The NVD4000 DCG focuses on advanced CNC control, high-precision positioning, .The NVD 5000 α1 focuses on advanced CNC control, high-precision positioning, .Machine size : 61.3 × 128.9 × 104.3 in. Mass of machine: .

Highest precision, rigidity as well as maximum flexibility in the field 3-axis .

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z . 3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and .

datron cnc price list

axis identification in cnc machine

eastwood 12 inch box and pan sheet metal brake

Three-axis CNC milling machines are versatile, capable of machining a wide range of materials. Metals like aluminum, brass, copper, steel, and titanium are commonly processed due to their excellent machinability and industrial .

What is a 3-axis CNC Milling Machine? A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to .

What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes .The high-speed milling solution that set the standard for performance and precision. The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the .

With additional coding, you can upgrade to a 3 axis CNC milling machine. The data only needs to be entered once for multiple uses. The 3 axis CNC machine definition gives the machine the ability to move three different .As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.

Industrial-grade, 3-Axis and 5-Axis CNC machines made in the USA and backed by the industry’s best customer service. DMS CNC routers offer a universal platform ideal for configurability for a myriad of applications.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.Three-axis CNC milling machines are versatile, capable of machining a wide range of materials. Metals like aluminum, brass, copper, steel, and titanium are commonly processed due to their excellent machinability and industrial applications. What is a 3-axis CNC Milling Machine? A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth.

What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes up and down.The high-speed milling solution that set the standard for performance and precision. The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge . With additional coding, you can upgrade to a 3 axis CNC milling machine. The data only needs to be entered once for multiple uses. The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously.

As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.

Industrial-grade, 3-Axis and 5-Axis CNC machines made in the USA and backed by the industry’s best customer service. DMS CNC routers offer a universal platform ideal for configurability for a myriad of applications.

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.Three-axis CNC milling machines are versatile, capable of machining a wide range of materials. Metals like aluminum, brass, copper, steel, and titanium are commonly processed due to their excellent machinability and industrial applications. What is a 3-axis CNC Milling Machine? A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth.

What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes up and down.The high-speed milling solution that set the standard for performance and precision. The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge . With additional coding, you can upgrade to a 3 axis CNC milling machine. The data only needs to be entered once for multiple uses. The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously.As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.

3 axis vertical milling machine

3 axis manual milling machine

Learn to Weld: Beginning MIG Welding and Metal Fabrication Basics - Includes .

3 axis cnc milling machine system|datron cnc price list