sheet metal bracket drawing Tags: bracket model, sheetmetal btacket design, sheet metal bracket, in this tutorial we design a steel bracket by using a sheet,

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal design guidelines pdf

3 · sheet metal design calculations pdf

4 · sheet metal bracket design guidelines

5 · sheet metal basic design guidelines

6 · existing designs for brackets

7 · basics of sheet metal design

The primary rule is that you must not enter a box junction unless your exit is clear. This means you should only proceed into the junction if there is enough space on the other side for your vehicle to leave without stopping within the yellow grid.

Bendy metal! Let's get to it. In this episode, we'll be modelling a sheet metal bracket, flat-patterning it, and creating a 2D drawing in Autodesk Fusion 360.

Join this channel to get access to perks:https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinFOR DRAWING .

sheet metal rib design guidelines

sheet metal fabrication design guide

Solidworks Sheet metal tutorial Steel Bracket. / @cadcamtutorialbymahtabalam You Can Support our Channel for more tutorials. we will learn sketch,sheet metal base flange, . In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, .In this exercise, you’ll create a sheet metal bracket. You’ll use a combination of different flange features to create the base and utilize sheet metal features to finish the part. Tags: bracket model, sheetmetal btacket design, sheet metal bracket, in this tutorial we design a steel bracket by using a sheet,

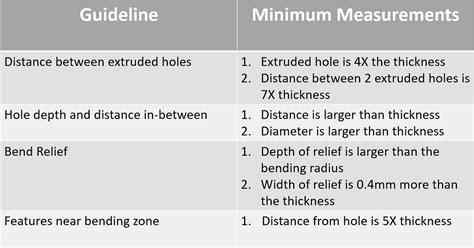

Evaluating the manufacturing feasibility of sheet metal brackets is crucial to ensure that the design can be produced efficiently, cost-effectively. Whether the geometry required can be manufactured through sheet metal .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal .Dongguan Jiatong(Xunjia) Precision Hardware Products Co., Ltd Was Established in March 2011 and located in Humen Town, Guangdong Province. The factory has an area of about 8,200 squar e meters and is a professional .1. The document provides instructions for creating sheet metal brackets and parts using Solidworks. 2. Exercise 1 involves using base flanges, cuts, and chamfers to create a sheet metal bracket based on given dimensions and design intent. 3. Exercise 2 uses flange features to create another part, demonstrating skills like base flanges, sheet metal parameters, edge flanges, .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! This Autodesk Inventor tutorial displays the modeling process of a 'Mounting Bracket' model which is created by using Sheet Metal functionality of Autodesk I.we will learn sheet metal basic features like Base flange, Edge Flange, Corner relief and Extruded Cut in Solidworks sheet metal.1)Solidworks tutorial for Be. Jackson K W Tang Autocad Tricks

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!This resource contains information about print out drawing and tape to sheet metal as a guide. Browse Course Material Syllabus Calendar Lecture Notes Recitations . MIT2_007s09_metal_bracket.pdf. Description: This resource contains information about print out drawing and tape to sheet metal as a guide. Resource Type: If we decide to create this sheet metal angle bracket using a press brake, our scope is further narrowed. . When the three legs are fastened to a flat surface, the legs pull together and draw additional strength from the surface to which the bracket is mounted. This bracket will be stronger than the last design, yet it is still not as strong .

Last updated on January 29th, 2024 at 12:53 pm. At Approved Sheet Metal, our sheet metal fabrication experts fabricate brackets for product developers across the country that design for a broad range of commercial, and military applications. In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore .The brackets is used for keeping the machine parts support and protected.But nowadays, the application of stents is extremely extensive, which can be encountered everywhere in work and life, such as tripods for cameras, cardiac stents used in the medical field, etc.We are specialized in manufacturing a sheet metal brackets.These are manufactured by conducting stamping or . Source: www.pinterest.ca I want to practice please. Sheet metal 2d drawings for practice pdf 2012 solidworks help dxf/dwg files (*.dxf *.dwg files) another area where we can practice our cad skills is to draw the neutral axis on a side view of the drawing and use the list function to retrieve the length of the components of the sheet metal allowance.Improve your SolidWorks skills with this advanced sheet metal exercise. Learn how to create precise and detailed technical drawings for electrical devices. . Solidworks Sheet Metal Drawings. Cad Drawing Mechanical. Sheet Metal Design. Sheet Metal Drawing. Gear Drawing. . Autodesk inventor sheet metal steel bracket. Join this channel to get .

sheet metal design guidelines pdf

For example I have no idea where the obround is located or even how wide this "L" bracket is. 5 - get yourself a drawing border . With sheet metal, I also put forming information. inside bend radius, 'vee' information, bend deduction, . BRACKET From a 2D Drawing Objective Create Bracket from the 2D drawing. Introduction Sheet Metal Brackets are the small metallic components which are used in various different industrial utilities for fitting, fixing, holding and fastening. In this challenge we are designing a bracket from its 2D drawing. Methodology Description.I have a plethora of files I could provide you to practice with and draw, but none of them are sheet metal.ipt. rupesh dewangan. Answered on 27 Aug, 2013 12:17 PM Hi, please do practice this two drawing. . fab_drawing_3A.jpg .This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles, while very appropriate for others. Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical.

In this video we are going to take a real world bracket and model it in Fusion 360 using Sheet Metal tools. While it might seem simple this bracket presents. Sheet metal bracket is a part made of thin metal plates. People use it to support, fix, or connect other components. This helps ensure the stability and functionality of the overall structure. . What Exactly is Deep Drawing Deep drawing is a kind of metal processing technology that causes a large degree of plastic. read more . 25 Sep 25/09 .

For example, a simple 90 degree bracket with holes in each face will have hole to bend tolerances dictated by the part profile tolerances. Bend angles. . Before applying GD&T to sheet metal drawings, remember that sheet metal components are relatively compliant. This means they conform to the components they are assembled with.

To create the necessary orthographic views for the sheet metal bracket, we will need to draw the front, top, and right-side views. 1. Front View: - The front view will show the bracket as if looking at it directly from the front. - Draw a rectangle to represent the base of the bracket. - Add the two vertical arms extending upwards from the base.Sheet Metal Bracket, Mounting Bracket. Send Us the Drawings for Profefessional Services and Accurate Cost Estimation of JIATONG XJ Origin Factory Competitive Prices. Welcome Your Visit or Video Audit onsite. . Brushed The so-called sheet metal drawing is to place the material between the upper and lower wheels of the wire drawing machine, and .This Pin was discovered by Mahtabalam Khan. Discover (and save!) your own Pins on Pinterest Sheet metal brackets present a unique situation. Sheet metal brackets are often first defined by a flat pattern shape that is cut from raw sheet metal. And sometimes the bracket holes are produced as part of this flat pattern. It is usually more cost effective to put all of the features, including holes, in the flat pattern.

This technique is commonly seen on construction brackets. The exact geometry of ribs and material response is tooling dependant, so consult with your manufacturer during the design process. . For your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing . In this episode, we'll be modelling a sheet metal bracket, flat-patterning it, and creating a 2D drawing in Autodesk Inventor. Bendy metal! Let's get to it!T.

sheet metal design calculations pdf

sheet metal bracket design guidelines

sheet metal basic design guidelines

existing designs for brackets

Yes, you can. One way to do this is to cement a slip/male thread connector onto the end of the PVC conduit. Insert this into your box and fasten with a 1" lock nut. But wait, there is a catch. You are using 1" PVC conduit. Now you need holes suitable for 1". You may have to get large metal boxes [4 11/16"] which have punch-outs for 1".

sheet metal bracket drawing|sheet metal fabrication design guide