aluminum extrusion and fabric Aluminum extrusion is a versatile and highly efficient manufacturing process that has revolutionized various industries. From aerospace to automotive, construction to electronics, aluminum extrusion offers a wide range of benefits that make it . $28.05

0 · list of aluminum extruders

1 · how strong is aluminum extrusion

2 · different types of aluminum extrusions

3 · aluminum extrusion temperature chart

4 · aluminum extrusion size chart

5 · aluminum extrusion process chart

6 · aluminum extrusion catalog pdf

7 · aluminum extrusion catalog

Introducing the Wardrobe Cabinet, a remarkable closet organizer in a flawless white finish. Made from high-quality MDF, this wardrobe is designed for increased sturdiness and durability.

list of aluminum extruders

Discover the art of aluminum extrusion, a key manufacturing process that transforms aluminum alloy into versatile cross-sectional profiles for use across various industries. This guide covers every step of the process, . Aluminum extrusion is a meticulous, step-by-step process that transforms raw aluminum into highly functional profiles. Understanding each stage helps explain why this .

metal jewellery box online india

Aluminum extrusion is a technology that transforms aluminum alloys into objects with defined cross-sectional profiles. Imagine pushing a malleable material into a shaped hole in a mold, like we squeeze toothpaste . Aluminum extrusion is a versatile manufacturing process that allows for the creation of precision profiles used in a wide range of applications. In this comprehensive guide, we will unravel the intricacies of the aluminum .Aluminum extrusion is a versatile and highly efficient manufacturing process that has revolutionized various industries. From aerospace to automotive, construction to electronics, aluminum extrusion offers a wide range of benefits that make it .

Aluminum extrusion is a cost-effective and efficient process for creating products with complex shapes and designs. The extrusion process involves pushing heated aluminum through a die to create a specific shape, .Aluminum extrusion refers to a process for manufacturing aluminum profiles. In this process, manufacturers will heat aluminum ingots to a high temperature. Then they will extrude them .

Aluminum extrusion is a versatile manufacturing process known for its ability to create customized solutions for various needs. It offers advantages like flexible design, precise shaping, and the ability to meet specific . Aluminum extrusion stands as one of the most versatile and efficient methods for shaping aluminum into complex profiles used in a multitude of industries. From architectural structures to automotive components, the process of . Discover the art of aluminum extrusion, a key manufacturing process that transforms aluminum alloy into versatile cross-sectional profiles for use across various industries. This guide covers every step of the process, from die preparation to final product creation, offering insights into how this method leverages aluminum's properties for high .

Aluminum extrusion is a meticulous, step-by-step process that transforms raw aluminum into highly functional profiles. Understanding each stage helps explain why this manufacturing technique is favored across so many industries. Aluminum extrusion is a technology that transforms aluminum alloys into objects with defined cross-sectional profiles. Imagine pushing a malleable material into a shaped hole in a mold, like we squeeze toothpaste out of a tube, and you're on the right track. Aluminum extrusion involves heating and pushing aluminum alloy through a die with a predesigned cross-sectional shape. A firm ram pushes the aluminum through the die and pulls it along a runout table during the operation. Aluminum extrusion is a versatile manufacturing process that allows for the creation of precision profiles used in a wide range of applications. In this comprehensive guide, we will unravel the intricacies of the aluminum extrusion process, providing a step-by-step explanation from the raw material stage to the creation of these profiles.

Aluminum extrusion is a versatile and highly efficient manufacturing process that has revolutionized various industries. From aerospace to automotive, construction to electronics, aluminum extrusion offers a wide range of benefits that make it an attractive choice for designers, engineers, and manufacturers alike. Aluminum extrusion is a cost-effective and efficient process for creating products with complex shapes and designs. The extrusion process involves pushing heated aluminum through a die to create a specific shape, making it ideal for .Aluminum extrusion refers to a process for manufacturing aluminum profiles. In this process, manufacturers will heat aluminum ingots to a high temperature. Then they will extrude them into the desired shape through a die with a specific hole pattern. Eventually, it will achieve a variety of complex aluminum profiles. Aluminum extrusion is a versatile manufacturing process known for its ability to create customized solutions for various needs. It offers advantages like flexible design, precise shaping, and the ability to meet specific performance requirements.

Aluminum extrusion stands as one of the most versatile and efficient methods for shaping aluminum into complex profiles used in a multitude of industries. From architectural structures to automotive components, the process of . Discover the art of aluminum extrusion, a key manufacturing process that transforms aluminum alloy into versatile cross-sectional profiles for use across various industries. This guide covers every step of the process, from die preparation to final product creation, offering insights into how this method leverages aluminum's properties for high . Aluminum extrusion is a meticulous, step-by-step process that transforms raw aluminum into highly functional profiles. Understanding each stage helps explain why this manufacturing technique is favored across so many industries.

Aluminum extrusion is a technology that transforms aluminum alloys into objects with defined cross-sectional profiles. Imagine pushing a malleable material into a shaped hole in a mold, like we squeeze toothpaste out of a tube, and you're on the right track. Aluminum extrusion involves heating and pushing aluminum alloy through a die with a predesigned cross-sectional shape. A firm ram pushes the aluminum through the die and pulls it along a runout table during the operation. Aluminum extrusion is a versatile manufacturing process that allows for the creation of precision profiles used in a wide range of applications. In this comprehensive guide, we will unravel the intricacies of the aluminum extrusion process, providing a step-by-step explanation from the raw material stage to the creation of these profiles.Aluminum extrusion is a versatile and highly efficient manufacturing process that has revolutionized various industries. From aerospace to automotive, construction to electronics, aluminum extrusion offers a wide range of benefits that make it an attractive choice for designers, engineers, and manufacturers alike.

Aluminum extrusion is a cost-effective and efficient process for creating products with complex shapes and designs. The extrusion process involves pushing heated aluminum through a die to create a specific shape, making it ideal for .Aluminum extrusion refers to a process for manufacturing aluminum profiles. In this process, manufacturers will heat aluminum ingots to a high temperature. Then they will extrude them into the desired shape through a die with a specific hole pattern. Eventually, it will achieve a variety of complex aluminum profiles.

how strong is aluminum extrusion

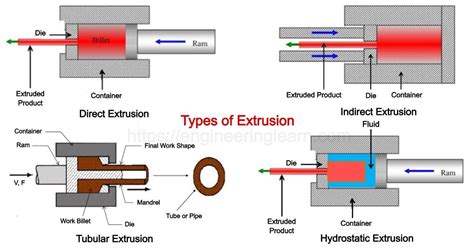

different types of aluminum extrusions

metal japanese box with dragons and honeycomb bottom value

aluminum extrusion temperature chart

Walnut Tree Junction signalbox controlled two junctions at Taffs Well on the ex-Taff Vale Cardiff-Merthyr Tydfil line. At Walnut Tree Junction itself, the "big hill" up to Aber Jct on the Rhymney valley line diverged. The signal in the foreground is the down main innerhomes bracket.

aluminum extrusion and fabric|how strong is aluminum extrusion