cnc brass machining low pressure die casting Low-pressure die casting refers to the process of injecting melted metal into a mold with low force, usually within 1-2 bar. In this method, metals are first liquefied in a furnace and then moved to a pressure chamber. Rayon is a fabric made of semi-synthetic fiber. This makes it a soft and comfortable fabric. Because the fabric also has a luxurious appearance is it a widely used fabric in the Fashion industry.

0 · what is die casting

1 · low pressure die casting methods

2 · low pressure die casting chart

3 · how does die casting work

$34.99

what is die casting

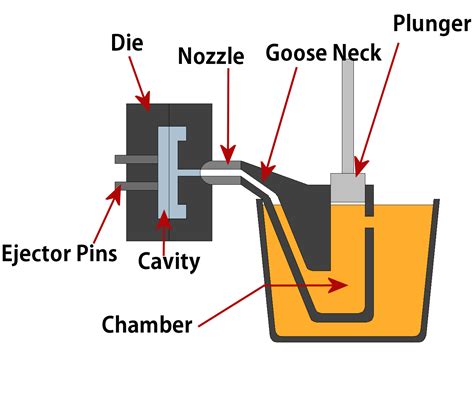

Low Pressure Die Casting (LPDC) is a casting method where molten metal is injected at low pressure (approximately 1 bar) into a mold or die. This process is highly suitable for . Low-pressure die casting refers to the process of injecting melted metal into a mold with low force, usually within 1-2 bar. In this method, metals are first liquefied in a furnace and then moved to a pressure chamber.

At JTR Machine, we can provide high-pressure die casting or low-pressure die casting according to your production needs to ensure product quality. High-pressure casting uses a hydraulic .

2007 ford edge smart junction box

Low Pressure Die Casting (LPDC) is a casting method where molten metal is injected at low pressure (approximately 1 bar) into a mold or die. This process is highly suitable for manufacturing complex shapes such as gears, engine blocks, and other intricate components. Low-pressure die casting is used in the automotive industry to produce components such as engine blocks, cylinder heads, and transmission cases. The process provides high accuracy and a superior surface finish, making it suitable for the manufacture of high-performance engine components. Low-pressure die casting refers to the process of injecting melted metal into a mold with low force, usually within 1-2 bar. In this method, metals are first liquefied in a furnace and then moved to a pressure chamber.At JTR Machine, we can provide high-pressure die casting or low-pressure die casting according to your production needs to ensure product quality. High-pressure casting uses a hydraulic cylinder to drive the injection head to press the metal liquid into the mold cavity at high speed.

G.W.P. AG manufactures ready-to-install aluminum low-pressure diecast parts for industry. We specialize in low-pressure gravity diecasting in small and medium-sized batches. From its name, low pressure die casting involves injecting the molten material into the die-cast under a well-controlled low pressure that gives the process advantages. For example, it allows accurate manufacturing of axially symmetrical wheels, so the automotive industries are top users of the process.

For low-volume production, CNC machining is ideal as it does not need tooling costs. But, when it comes to high-volume production, die casting always wins due to its quality and consistency. CNC machining needs a post-cutting process and rechecking the program with every unique shape.Brass die-casting can be used to produce complicated metal designs at high volume, that too at very low costs. Some of the biggest advantages of brass die casting are low tooling costs, dimensional accuracy of 0.1 mm, and the wall thickness can go up to 0.75 mm.

Die casting involves injecting molten metal into a mold cavity. That’s precisely what aluminum low pressure die casting is. The only difference is that the method of production utilizes pressure rather than gravity. Let’s get technical for a minute! The die-casting machine typically has a melting furnace and a holding furnace just below the cast. Low Pressure Die Casting (LPDC) Modern pressure die casting is more like an umbrella term for different types of casting processes. All the methods share the same pressurizing and speeding principle.Low Pressure Die Casting (LPDC) is a casting method where molten metal is injected at low pressure (approximately 1 bar) into a mold or die. This process is highly suitable for manufacturing complex shapes such as gears, engine blocks, and other intricate components. Low-pressure die casting is used in the automotive industry to produce components such as engine blocks, cylinder heads, and transmission cases. The process provides high accuracy and a superior surface finish, making it suitable for the manufacture of high-performance engine components.

Low-pressure die casting refers to the process of injecting melted metal into a mold with low force, usually within 1-2 bar. In this method, metals are first liquefied in a furnace and then moved to a pressure chamber.At JTR Machine, we can provide high-pressure die casting or low-pressure die casting according to your production needs to ensure product quality. High-pressure casting uses a hydraulic cylinder to drive the injection head to press the metal liquid into the mold cavity at high speed.

G.W.P. AG manufactures ready-to-install aluminum low-pressure diecast parts for industry. We specialize in low-pressure gravity diecasting in small and medium-sized batches.

From its name, low pressure die casting involves injecting the molten material into the die-cast under a well-controlled low pressure that gives the process advantages. For example, it allows accurate manufacturing of axially symmetrical wheels, so the automotive industries are top users of the process.

For low-volume production, CNC machining is ideal as it does not need tooling costs. But, when it comes to high-volume production, die casting always wins due to its quality and consistency. CNC machining needs a post-cutting process and rechecking the program with every unique shape.Brass die-casting can be used to produce complicated metal designs at high volume, that too at very low costs. Some of the biggest advantages of brass die casting are low tooling costs, dimensional accuracy of 0.1 mm, and the wall thickness can go up to 0.75 mm. Die casting involves injecting molten metal into a mold cavity. That’s precisely what aluminum low pressure die casting is. The only difference is that the method of production utilizes pressure rather than gravity. Let’s get technical for a minute! The die-casting machine typically has a melting furnace and a holding furnace just below the cast.

2007 ford e350 power distribution box fuse diagram

CNC sheet metal bending is one of the most underrated processes available for sheet metal part production. With bending, it’s possible to produce a wide variety of part geometries without tooling, at fast lead times, with high levels of repeatability and through automated processes.

cnc brass machining low pressure die casting|how does die casting work