application of cnc machine pdf • CNC – Computer Numerical Control ØCNC machines use a computer to assist and improve functionality of number and code control. ØIn the 1960’s, CNC machines became available . Electrical boxes come in different types, shapes, and sizes, each with its specific use and installation requirements. The most common types of electrical boxes include junction boxes, outlet boxes, switch boxes, and ceiling .

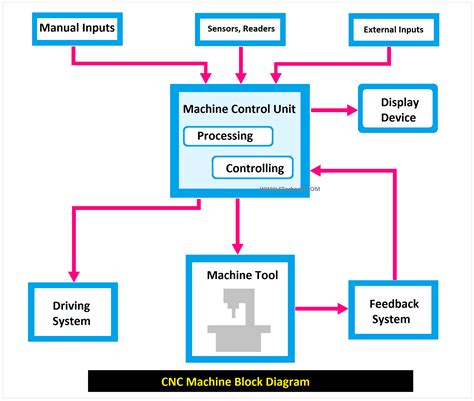

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Types of Heat Treatment Processes. Heat treatment encompasses various processes, each tailored to achieve specific results in altering the properties of metals. Hardening. The primary purpose of hardening is to increase the hardness and strength of metals.

• CNC – Computer Numerical Control ØCNC machines use a computer to assist and improve functionality of number and code control. ØIn the 1960’s, CNC machines became available .11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .

cutting tools automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate .

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. .What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .

Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.

NC Technology Numerical control technology has a wide range of applications in the field of mechanical processing, especially Siemens, FANUC, HEIDENHAIN, and other numerical .We now have the ingredients for a true CNC machine: data storage and transmission; precise motion control and positional measurement; and a computerized system that provides analysis .• CNC – Computer Numerical Control ØCNC machines use a computer to assist and improve functionality of number and code control. ØIn the 1960’s, CNC machines became available with timesharing on mainframe computers. True NC machines continued to be built. ØBy the 1970’s, specialized computers were being manufactured for CNC controls.

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

cutting tools automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate measuring machine, electronic assembly, tape laying and filament winding machines for composites etc.Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.NC Technology Numerical control technology has a wide range of applications in the field of mechanical processing, especially Siemens, FANUC, HEIDENHAIN, and other numerical control systems that occupy a large proportion in the CNC machine tool control system.

We now have the ingredients for a true CNC machine: data storage and transmission; precise motion control and positional measurement; and a computerized system that provides analysis and optimization of the point-by-point tool path needed to make a three-dimensional shape.• CNC – Computer Numerical Control ØCNC machines use a computer to assist and improve functionality of number and code control. ØIn the 1960’s, CNC machines became available with timesharing on mainframe computers. True NC machines continued to be built. ØBy the 1970’s, specialized computers were being manufactured for CNC controls.11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.cutting tools automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate measuring machine, electronic assembly, tape laying and filament winding machines for composites etc.Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool. Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.NC Technology Numerical control technology has a wide range of applications in the field of mechanical processing, especially Siemens, FANUC, HEIDENHAIN, and other numerical control systems that occupy a large proportion in the CNC machine tool control system.

schematic diagram of cnc machine

products made by milling machine

industries that use cnc machines

In this blog, these seven basic types of sheet metal joints used in various industries are described. This article also explains their major characteristics, advantages, and disadvantages as well as compares the welding and riveting, adhesive bonding, and bolting.

application of cnc machine pdf|cnc machine work needed