cnc lathe machine coordinate system The values of X (U) and Z (W) represent the coordinates of the hypothetical intersection point between adjacent lines AD and DE within the workpiece coordinate system, where X and Z are the absolute coordinate . tells you exactly how much materials you need. You have to build a "small house layout" then a "main hall". After that, you just pick what you want for the three wings. East, North, & West. Add.

0 · coordinate systems in cnc machines

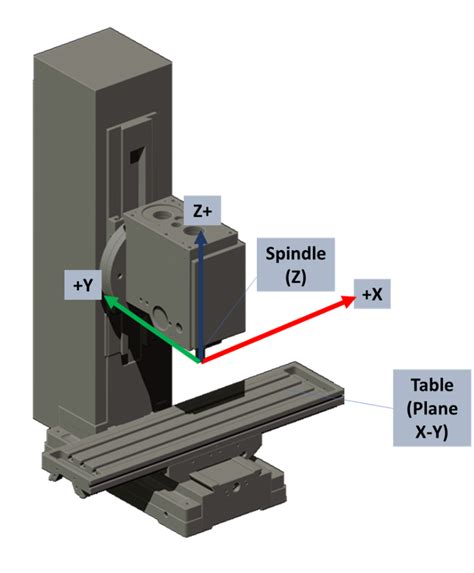

1 · cnc xyz axis chart

2 · cnc mill axis diagram

3 · cnc machine axis locations diagram

4 · cnc machine axis identification

5 · cnc cartesian coordinate system

6 · cnc axis chart

7 · cm meaning in cnc field

ANSI and ISO Twist drill size chart Fractional and Metric Sizes per. ANSI/ASME .

Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment. What kind of coordinate system is used in CNC machining? Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate . Machine tool coordinate system. The machine tool's built-in coordinate system is used to calculate the coordinates of the machined parts inside the tool, as well as the .

One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC .

The values of X (U) and Z (W) represent the coordinates of the hypothetical intersection point between adjacent lines AD and DE within the workpiece coordinate system, where X and Z are the absolute coordinate .CNC machines use coordinate systems for direction and distances to control the machine's movements accurately. Understanding the machine's coordinate system is crucial for .

When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis coordinates should be dimensioned from the face of the .

The coordinate system that is built into the machine is called the machine coordinate system. The other coordinate system is the workpiece coordinate system or work coordinate system . CNC operators control this coordinate .Coordinates for the CNC Lathe provides an overview of the coordinates used to program cutting operations on CNC lathes or turning centers. It introduces the systems of both Cartesian and .There are several types of machine coordinate systems commonly used in CNC machining, including Cartesian coordinate systems, polar coordinate systems, and cylindrical coordinate .

Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment. What kind of coordinate system is used in CNC machining? Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space. Machine tool coordinate system. The machine tool's built-in coordinate system is used to calculate the coordinates of the machined parts inside the tool, as well as the particular positions of its moving components (such as tool change points and reference points) and its range of motion (such as the range of travel, protected areas).

One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications. The values of X (U) and Z (W) represent the coordinates of the hypothetical intersection point between adjacent lines AD and DE within the workpiece coordinate system, where X and Z are the absolute coordinate values, and .CNC machines use coordinate systems for direction and distances to control the machine's movements accurately. Understanding the machine's coordinate system is crucial for operators,programmers,and anyone involved in producing the desired output with precision.

When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis coordinates should be dimensioned from the face of the .The coordinate system that is built into the machine is called the machine coordinate system. The other coordinate system is the workpiece coordinate system or work coordinate system . CNC operators control this coordinate system by setting the axes for X, Y, and Z.

Coordinates for the CNC Lathe provides an overview of the coordinates used to program cutting operations on CNC lathes or turning centers. It introduces the systems of both Cartesian and polar coordinates and describes how Cartesian axes are used on a CNC lathe.There are several types of machine coordinate systems commonly used in CNC machining, including Cartesian coordinate systems, polar coordinate systems, and cylindrical coordinate systems. Each type offers unique advantages and is suitable for specific applications.Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment. What kind of coordinate system is used in CNC machining? Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space.

Machine tool coordinate system. The machine tool's built-in coordinate system is used to calculate the coordinates of the machined parts inside the tool, as well as the particular positions of its moving components (such as tool change points and reference points) and its range of motion (such as the range of travel, protected areas).One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications. The values of X (U) and Z (W) represent the coordinates of the hypothetical intersection point between adjacent lines AD and DE within the workpiece coordinate system, where X and Z are the absolute coordinate values, and .

CNC machines use coordinate systems for direction and distances to control the machine's movements accurately. Understanding the machine's coordinate system is crucial for operators,programmers,and anyone involved in producing the desired output with precision.When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis coordinates should be dimensioned from the face of the .The coordinate system that is built into the machine is called the machine coordinate system. The other coordinate system is the workpiece coordinate system or work coordinate system . CNC operators control this coordinate system by setting the axes for X, Y, and Z.

Coordinates for the CNC Lathe provides an overview of the coordinates used to program cutting operations on CNC lathes or turning centers. It introduces the systems of both Cartesian and polar coordinates and describes how Cartesian axes are used on a CNC lathe.

coordinate systems in cnc machines

cnc xyz axis chart

cnc mill axis diagram

Metal ammo boxes are the logical choice if you intend to store the ammunition in a location where it will be destroyed or stolen since they are made to be robust and durable. A metal box guards the ammunition against theft, water damage, dust damage, sunshine damage, and other hazards.

cnc lathe machine coordinate system|cnc mill axis diagram