sheet metal hammer uses A sheet metal hammer is a type of hammer designed specifically for use in sheet metal work. It is a specialized tool that has a distinctive shape and is used to shape and manipulate sheet . So the FIRST thing is to get in the passenger footwell when the relay is buzzing/clicking, and feel the case of the large 30G relay on the right side of the JB (Junction Box) Fuse Panel to see if that is vibrating.

0 · sheet metal shaping hammers

1 · sheet metal hammers types

2 · sheet metal hammer harbor freight

3 · sheet metal edge shapers

4 · sheet metal edge former

5 · planishing hammers for working metal

6 · metalworking hammer

7 · cp planishing hammer dies

Typical applications include connections between multiple storm water pipes. Junction boxes are also used for protecting the junction of telecommunications, power, fiber optic, and other utility cabling.

sheet metal shaping hammers

Planishing Hammers: Designed to form mild sheet metal up to 16 gauge or aluminum up to 1/8” thick, these hammers are widely chosen for fine shaping and smoothening .A sheet metal hammer is a type of hammer designed specifically for use in sheet metal work. It is a specialized tool that has a distinctive shape and is used to shape and manipulate sheet .

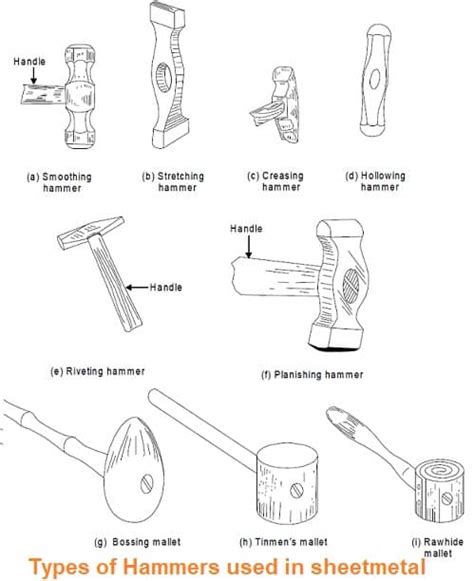

In this post, we’ll explore the various types of hammers, categorizing them into general-purpose hammers, specialized hammers for specific tasks, metalworking hammers, soft-faced/non-marring hammers, .

cnc machining brass fittings

A round-head hammer is commonly known as a ball peen hammer, used in metalworking for riveting and shaping metal. Explore various types of hammers and their uses. .Choose from our selection of sheet metal forming hammers, riveting hammers, ball peen hammers, and more. In stock and ready to ship.Fig shows the various types of hammers used in sheet metal work for forming shapes. The uses of different kind of hammers are given as under: (a) Smoothing hammer. Smoothing hammer (Fig. (a)) is used for leveling and smoothing a .Choosing a perfect type of hammer for metalsmithing or jewelry work is rarely as simple as picking up the one closest to you. Different types of hammers have different uses and each style is perfectly suited for its intended use.

Tinner’s or sheet metal hammers, can also be instrumental in forming bends or seams in the absence of more specialized tools. This is even more noticeably the case when a sheet metal hammer has a wedged face on . Many types of hammers are suited to highly specific use cases within certain professions. For instance, a blacksmithing hammer is used for metalwork, so it’s unlikely to find its way into a general contractor’s or DIY .

It was with me for many years and several different jobs, until I eventually lost it if I was looking for a quality sheet metal hammer to use as a professional I would not hesitate to buy one for myself. Read more. Helpful. Report. Adam Zack. 5.0 out of 5 .Raising Hammers. Used in conjunction with a raising stake to form sheet metal into bowls, vases, and other hollow forms. This hammer is used on the outside surface of the metal, with the sheet positioned on the raising stake at a slight .

Ball peens are used more for machining and sheet metal type stuff. . It's the name for, and the purpose of the hammer it is used for "peening" used a lot when I was a kid, peening rivits when installing new sickle sections on a sickle bar for our hay mower and other assorted rivits, also used what was called a "bucking block" on the back side .A sheet metal hammer is a type of hammer designed specifically for use in sheet metal work. It is a specialized tool that has a distinctive shape and is used to shape and manipulate sheet metal without causing damage to the surface. Sheet metal hammers come in a variety of sizes and shapes, each designed for specific tasks and preferences. In the workshops, the hammers used by the fitter are generally 0.33 to 0.45 Kg in weight. Heavy hammers are 0.91 kg in weight. Hammer has the following part, which has been shown above. . It is also used to strike blows on a metal sheet up to a certain depth. These types of hammers are shown in the figure. Its weight is between 0. 11 to 0.91 kg.ESTWING Tinner's Hammer - 12 oz Sheet Metal Hammer with Forged Steel Construction & Shock Reduction Grip - T3-12 Visit the Estwing Store 4.8 4.8 out of 5 stars 3,266 ratings

Versatile Design for Wide Applications:A highly popular and unique hammer used in metal sheet and pipe manufacturing, featuring a durable and comfortable rubber grip that reduces fatigue. Exceptionally balanced with a polished surface and square head. A multi-functional hammer that meets most hammering needs, suitable for both nailing and .Malco’s Sheet Metal Setting Hammer comes in two different grips, leather (SH3) or vinyl (SH3V) gripped. The leather grip of Malco’s SH3 model conforms a permanent bond between the user’s hand for ultimate comfort and ease of use. The SH3V model is made with a molded on vinyl grip. The grip helps minimize recoil, while also staying .

SLNIHAMS Tinner's Hammer, 18oz Sheet Metal Hammer Tools, Hvac Tool Tinners Hammer with Forged Steel Construction and Shock Reduction Grip, Sheet Metal Hammers, Welding and Chipping Hammer - Amazon.com

Sheet metal - tools. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. what is the difference between mallets and hammers? a mallet uses a soft face made of plastic or rubber while a hammer is formed metal. 1 / 38. 1 / 38. Flashcards; Learn; Test; Match; Q-Chat; Created by. matix76. Share. Share. Get better grades with Learn. 82% of students .

Each and every car body shop, industrial machine shop, and automobile repair shop should select sheet metal hammering for their own sheet metal fabrication and repair needs as well. Power hammers are mechanically powered forging instruments that use electricity to raise the hammer and strike. Metalworkers have used power hammers since the late .This 18oz sheet metal hammer is equipped with a lacquer leather grip that conforms to the users hand over time This is easily the most popular Malco setting hammer on the market and is used by professionals worldwide One-piece forged, I-beam construction Fully polished heads with beveled face and are corrosion resistant Hammer sections are individually hardened and .Model 5300 Pneumatic “Pittsburgh Lock” Hammer. new. Manufacturer: Northern Machinery Sales; Powerful,Durable,Fast,Warranty Powerful . . . With an effective range of 30 to 18 gauge sheet metal, this “HEAVY-DUTY” performer has more than enough power to meet your most demanding applications. Durable . . . . Strike metal at 90 degrees or slightly off-center to avoid splintering. Use light taps on annealed or thin metal. Start gently and increase force as needed. Ball Peen Hammer Uses by Industry. Ball peen hammers are common in these metalworking trades: Blacksmithing – Shaping hot iron into tools, decor, and more.

BinaryABC Sheet Metal Hammer,Auto Body Planishing Hammer,Car Body Repair Tool,Autobody Tools and Equipment. . Used for pounding auto sheet metal before finishing. Use on flat and curved surfaces. Includes heavy shrinking hammer, pick and finish hammer, straight pein finishing hammer, heel dolly, utility dolly, double end dolly and curved .The KSEIBI 271450 Machinist Engineers Hammer is a must-have tool for anyone working with sheet metal. Made of forged steel, this hammer is built to last and withstand heavy use without compromising performance. Its cross peen .When doing steel and bodywork the "hammer" is the tool you to hit the metal, the "dolly: is the tool you hold on the other side to shape the metal. In this case you would use the handle to get the dolly into a tight space and hit against it from .

A Tinner's hammer is useful for bending sheet metal to secure connection points i.e. Pittsburgh Groove. The striking side is sometimes used to bend cleats after securing ducting. Seamers (a.k.a. Hand Brake tool) are used to bend with a wider grip and the finished product looks nicer than striking with the hammer. Versatile Design for Wide Applications:A highly popular and unique hammer used in metal sheet and pipe manufacturing, featuring a durable and comfortable rubber grip that reduces fatigue. Exceptionally balanced with a polished surface and square head. A multi-functional hammer that meets most hammering needs, suitable for both nailing and .

The Yoder K-90-M Power Hammer is the premier power hammer built for bending, forming and planishing light gauge shapes of sheet metal. They have numerous applications, including automotive parts, aerospace and custom sheet metal, and are used extensively in the aerospace industry as well as the build of custom cars and choppers, where perfect balance in a power .Sheet Metal Power Hammer Operators. Join group. About this group. Group is for traditional throw type power hammers to further the knowledge of it's members and share it's history. Not for the mini-hammers or reciprocating machines, air hammers or .

It smoothens off the finished sheet metal work. (g) Soft hammer or Mallets. Mallets (Fig. (g)) used during working with soft metal sheets. They may be of wood, rubber, or raw hide. A mallet strikes a blow with the minimum damage to the surface. In sheet metal work, the commonly used mallets are bossing mallet, tinman’s mallet (Fig. (h)), and .The Midwest Tool 18-ounce Sheet Metal Hammer is a high-quality tool built for tradespeople working on various HVAC and sheet metal projects. The unique cleat-slot design streamlines the installation of duct cleats enabling the user to quickly bend the cleat tabs with minimal motion. The shock-reducing design boasts a slip-resistant over-molded .

Straighten or bent sheet metal. Remove dents and deformation from parts made of sheet metal; Assembly of large injection molds, die casting dies etc. The basic job of the dead blow hammer in this field is to either put together or reshape metal, mostly sheet metal. Dead blow hammers work quite well in banging out dents in thin metal sheets. 6 .

The sheet metal hammer is an essential part of any tinsmith or coppersmith tool case. Read More. Steetz has a wide variety of hammers and mallets that are each designed with a specific purpose in mind including; tinners hammers, chasing and embossing hammers, non-rebounding or dead blow hammers and riveting hammers just to name a few. .Sheet Metal Hammer – 21oz Tinsmith Hammer with Integral Forging – Tin Hammer . Opens in a new window or tab. Brand New. .97. Buy It Now. Free shipping. Free returns. Last one. 1 watchers. Sponsored. shulamiteliyahu (512) 98.7%. Sleep Token Metal Hammer Hand Stamped Lyric Sheet Ltd Edition 300 Worldwide RARE.How a Planishing Hammer works: This machine is used for finishing metal to remove dents, to smoothen metal and to finely shape panels. . You can stretch, dome, and shape complex sheet metal parts for antique cars, hot rods, motorcycles, airplanes, sculptures, etc. • 16 Gauge (.006") Mild Steel Capacity • 11 Gauge (.120" or 1/8") Aluminum .

cnc machining bike parts factory

Measures, cuts, and welds pieces together according to specifications, blueprints, or directions. Connects pieces or secures seams by riveting, rolling, soldering, or using steel screws. Performs.

sheet metal hammer uses|cp planishing hammer dies