what is notching in sheet metal Notches are the inward cut from the edge of sheet metal with a measured angle suitable for a particular application. Notching is done either . There are dozens of weave patterns used to design the various metal fabrics used throughout the world of architectural design. That said, there are four main material categories that help describe the qualities of the metal fabric: wire mesh, cable mesh, fine mesh, and specialty mesh.

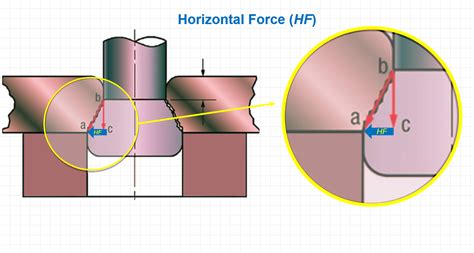

0 · stripping force in sheet metal

1 · slotting operation in sheet metal

2 · slitting process in sheet metal

3 · sheet metal notching machine

4 · protolabs sheet metal design guide

5 · notching operation in sheet metal

6 · notchers for sheet metal

7 · cutting clearance for sheet metal

Stainless steel: Known for corrosion resistance and strength, stainless steel brackets are ideal for outdoor applications where durability is paramount. Zinc-plated steel: Offering both strength and a protective zinc barrier, these brackets are a cost-effective option for various projects.

This metalworking process is used extensively to manipulate the size and shape of sheet metal. Notching typically requires the use of a punch .

It's actually a very important early step in cookware and general sheet metal builds, which will help account for turning for a wire, prepping a seam, folding an edge, or preparing to do a burr. Sheet metal notching creates precise cuts and openings in metal sheets, enabling parts to fit together seamlessly during assembly. Modern CNC notching machines achieve . Notches are the inward cut from the edge of sheet metal with a measured angle suitable for a particular application. Notching is done either .

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically . Designing Sheet Metal Notches, Tabs, and Slots. By Protolabs. Key Takeaways. Notches and tabs provide space for tools and aid in assembly. Notches should have a width of at least 0.040 in. or the material thickness, . After using the term "notch" and telling everyone to "notch your corners" when demonstrating all kinds of builds over the years, I realized I should probably. Notching sheet metal using hand tools may cause injuries and carpal tunnel for the operators. Simonds Inc. has developed a notching tool using the ergonomics.

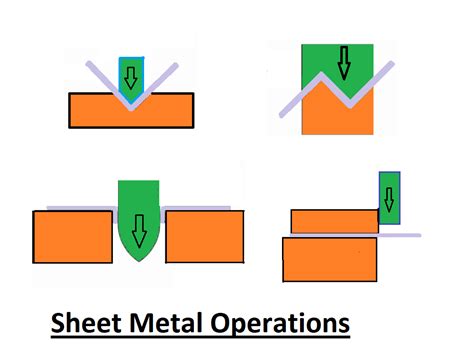

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .Like ductile metals, the ductile materials are rolled or hammered into a thin sheet in some special cases. This property of the material is known as Malleability.So, malleability is the property of the material that gives an identity of sheet metal. the sheet metal or malleable material should be plastic but it is not compulsory to be so strong.

Extend ductwork, create smooth corners, and install leak proof roofing with the ABN 10 Inch Sheet Metal Notching Snips. Outfitted with self-opening handles, this set of panel notchers operates with one hand on your tool and one hand on the material. Comfort grip thermoplastic rubber handle saves your hands from fatigue as you effortlessly slice . Notching machines are specialized metal fabrication equipment designed for precision cutting of metal plates, particularly for creating notches, angles, and intricate shapes in sheet metal. There are two primary categories of notching machines: adjustable angle and fixed angle. The adjustable angle variants offer a versatile range typically . Heavy Duty: Made from precision forged alloy steel, this sheet metal hand notcher works just as hard as you do. The v notcher’s compound spring design helps you easily notch sheet metal. 13/16” inch (2.1cm) maximum v notch cut depth.A subset of shearing, trimming and notching applications involve the removal of material from the edges or perimeter of a workpiece, typically applied to either sheet metal or tubing.While trimming applies to the removal of material with the main goal of reducing the size of the workpiece for workability or trimming down to the final dimensions, notching involves removing shapes or .

Browse top quality plate notchers for precise metal cutting and shaping. Choose from a variety of powerful hand notcher machines for sheet metal projects.

Elite Metal Tools sheet metal notcher is the highest quality and versatile corner notcher on the market, period. As far as sheet metal fabricating equipment is concerned, Elite Metal Tools sheet metal equipment offers superior machinery for a great value. Our sheet metal notchers consists of twelve different notching machines demonstrating the companies willingness to provide . Notching in sheet metal working refers to the activity of removing unwanted parts of the sheet metal around the edge areas, which will allow you to create a notch shape around the edges. This is an important process to do if you need to wrap the edges of the sheet metal around to the other side, such as when you are building enclosures or . Notching is a type of trimming operation in sheet metal manufacturing that involves removing material from the edge of a workpiece. This operation is used when the workpiece needs to have specific shapes or patterns on its edge.

stripping force in sheet metal

Study with Quizlet and memorise flashcards containing terms like true or false, a pictorial drawing shows the object after being formed?, true or false, notching and clipping remove portions of the metal to prevent overlapping and bulging on seams and edges?, the distance across the flat pattern or flat piece of metal before it is formed is called a? and others.Using the Sheet Metal workbench, I'm trying to design a part that looks almost exactly like the picture I've linked at the bottom. The sketch of a U-shape gets turned into a Base Bend and then the cutout is added by Sketch On Sheet. .

A sheet metal stamping process is a metalworking process carried out at room temperature wherein parts are both cut and shaped from a parent metal strip or. . Because notching is essentially performed on the edges, notching punches .

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to .In sheet metal, this question always creates some confusion. What is the difference between punching blanking and piercing? Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. Sheet metal notching creates precise cuts and openings in metal sheets, enabling parts to fit together seamlessly during assembly. Modern CNC notching machines achieve accuracies within 0.001 inches, enabling complex assemblies in industries from aerospace to consumer electronics. The choice of the notching method directly impacts product .

Sheet Metal Bend Notch . Hello! I didnt find an information on the web about how to make a triangle notches on a bends. I want the bending process to be easier for the guys to just export flat pattern to dxf, cut the part on laser cutting machine and simply allign notches to the blade to bend. Notching, is widely used in sheet metal manufacturing as hole punching. Common uses include those in which sheet metal will be bent or mechanically moulded in some way. What does Drilling mean? Drilling among the three methods that does not require shearing. Drilling is the process of removing material by using a drill bit. Sheet Metal Notching: What Is It? Sheet metal notching is a relatively simple process that makes up the backbone of a vast amount of our services. This metal-cutting process requires the use of sheet metal in the hands of a professional fabricator. Sheet metal notching is all about shearing or punching pieces of metal from the surrounding edges .

Notching is a precise metal-cutting technique specifically designed for sheet-metal, thin bar-stock, angle sections, or tubes. This process employs either shearing or punching methods in a press to cut down vertically and perpendicularly from the work-piece’s edge. What is A Notching Machine. A notching machine, also known as a notcher, is a specialized tool used in metalworking to create notches or cuts in metal sheets or plates.These machines typically consist of a sturdy frame with a cutting mechanism, which may be operated manually, mechanically, hydraulically, or even with CNC controls.That is partially right. Basically imagine a .25" thick sheet of metal with a 90 degree horizontal bend line at the top to create a 2" flange across the whole thing. Then on that same sheet metal, a vertical bend line at center of sheet, which will bend it in/angle it 30 degrees inward. I will try to add a picture also What Is A Hydraulic Notching Machine. A hydraulic notching machine is a specialized piece of equipment used in metalworking to create notches or cuts in sheet metal or metal plates. These machines utilize hydraulic power to exert force on a cutting tool, allowing for precise and efficient notching operations.

slotting operation in sheet metal

cnc machine brands for sale

cnc machine bozeman

slitting process in sheet metal

Electrical boxes are an essential part of any home electrical system. There are several types of electrical boxes, and they all house wiring connections, the parts of your electrical system where wires join an outlet, switch, or even other wires.

what is notching in sheet metal|protolabs sheet metal design guide