cnc machine coolant oil Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting . The ZARGES K470 aluminum shipping and storage case provides perfect protection, even under the most extreme conditions. The K470 is ATA 300 approved, lightweight, rugged, and dust and water resistant.

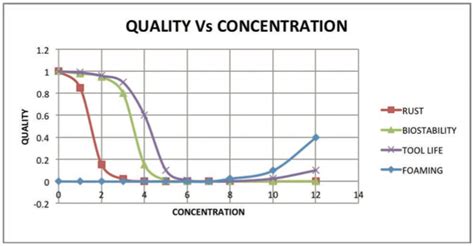

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Metal Fabrication Services from Zeus Metals. Providing all form of metal .

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid .Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting . Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut . Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant .

machine coolant concentration chart

coolant tank for cnc machine

Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, . Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess .Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, .

Choosing the appropriate type of coolant can significantly enhance the efficiency and longevity of your CNC machines. There are primarily two types of coolants used: water-based and oil-based solutions.

Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate . What is the Right Coolant for Your CNC Machine? Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following . Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal.

tuf tite 9 hole distribution box lid inspection port pic

coolant system for milling machine

trx4 metal axle housing phat

Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting performance, increased tool life, and better surface finishes. Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, synthetic fluids and semisynthetic fluids.

Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads.

Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads. Choosing the appropriate type of coolant can significantly enhance the efficiency and longevity of your CNC machines. There are primarily two types of coolants used: water-based and oil-based solutions.Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate cutting tools and work pieces.

What is the Right Coolant for Your CNC Machine? Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following . Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal.Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting performance, increased tool life, and better surface finishes.

coolant mixers for cnc equipment

Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 .

Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining

Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, synthetic fluids and semisynthetic fluids.

Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads.Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads. Choosing the appropriate type of coolant can significantly enhance the efficiency and longevity of your CNC machines. There are primarily two types of coolants used: water-based and oil-based solutions.

turck euro fast junction box

YoraHome 6550 Pro - Working area: 65cm x 50cm - Laser module: 10W optical power, 0.08x0.08mm compressed laser spot - Air assist: integrated nozzle in laser head, supplied air-pump -.

cnc machine coolant oil|machine coolant concentration chart