cnc machining mill The World’s Most Popular CNC Mills. VF Series. Small VF Series. Medium VF . The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 and must be painted visibly green.

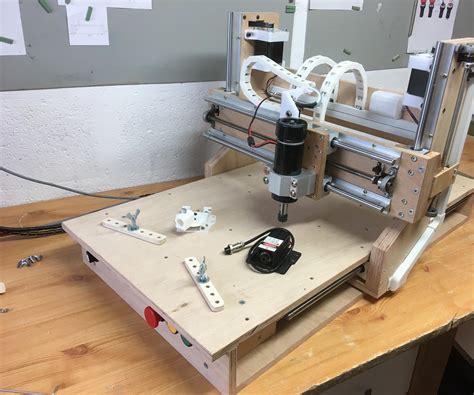

0 · hobby cnc milling machine

1 · cnc milling machine near me

2 · cnc milling machine for metal

3 · cnc mill for home shop

4 · cnc mill for hobbyist

5 · best home cnc milling machine

6 · best cnc milling machine 2022

7 · affordable cnc milling machines

Choosing the correct electrical junction box is crucial to ensure your electrical system’s proper functionality and safety. With so many options available in the market, it can be overwhelming to make the right choice.

A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to .

Haas Mini Mills are the industry standard for compact machining centers. They are .

The World’s Most Popular CNC Mills. VF Series. Small VF Series. Medium VF .

CNC Toolroom Mill with 30" x 16" x 16" travels and ATC CNY ONLY. Learn .

Drill/ Tap/ Mill Series; Toolroom Mills; Compact Mills; Gantry Series; SR Sheet .

Super-Speed 5-Axis CNC Vertical Mill with 40" x 25" x 25" travels CNY ONLY. .Large-Platform CNC Gantry Machines for Big Jobs. Haas gantry routers and mills .Powerful Vector Spindle Drives – The Haas-designed vector spindle drive uses .Compact CNC Vertical Mill with 12" x 10" x 14" travels CNY ONLY. Learn More .

The World’s Most Popular CNC Mills. VF Series. Small VF Series. Medium VF Series. Large VF Series. Videos. Build-&-Price. A Wide Range of Sizes and Features to Fit Any Shop’s Needs. The industry-leading Haas VFs are the .Haas Mini Mills are the industry standard for compact machining centers. They are perfect for schools, start-up shops, or as a first step into CNC machining. Loaded with full-size features, they are valuable additions for shops needing a .Discover Tormach’s CNC mills designed to fit in so your ideas can stand out. Easy to buy, learn, and use. Start building with precision-engineered parts today.

Quality Product Machining at Low Prices. CNC Masters is the premier source for CNC mills, CNC milling machines, and CNC lathes. Our high-quality computer numerical control products range from desktop CNC milling machines to .Based on high-speed, high-accuracy servo technology, FANUC’s CNC Systems maximize the performance of machine tools, such as improved productivity, high-speed, high-quality machining, and easy-to-use operability.Tormach makes CNC machines and automation tools that offer precision across a range of materials, without the need for expensive industrial three-phase power. Our machines cut wood, plastics, aluminum, steel, and titanium.What is CNC milling? In CNC milling, a milling tool with geometrically determined cutting edges rotates at high speed about its own axis. By advancing the tool or a workpiece in different axial directions, material is removed and a geometric .

Horizontal Mill: A Quick Overview. Whether you need a horizontal machining center for high-volume production and unattended operation or really big work cubes and maximum weight capacity, Haas has an HMC that should fit the bill. .

metal fabricators sarasota fl

Find CNC mills and lathes for sale. Enhance your precision, automation, and quality in cutting, shaping, and turning operations for diverse machining needs. . CNC Mill (803) Vertical Machining Center (650) CNC Lathe (500) Horizontal Machining Center (140) Router (104) EDM (21) Manual and Other Machining (19) Boring Mill (13) Fabrication (144)

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to .AFFORDABLE CNC MILLING IS HERE. The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances.

hobby cnc milling machine

A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece.This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] Milling covers a wide variety of different operations and machines, on scales from small individual .Okuma America Corporation helps users gain competitive advantage through the open possibilities of our CNC machine tools and advanced technologies. . Preview Connect Plan on a single machine with just a quick download from the Okuma App Store. View operating history and production rates in visual graph format and see alarm history with live .This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous 5-axis motion for contouring and complex machining. Haas VF-2SS + TR160

The original Kurt AngLock® vises were designed to provide precision part clamping for basic machining and milling applications. Our line of Kurt vises includes high precision CNC vises, 5-axis vises, rotary table workholding solutions for VMCs, and ToolBlox tombstones.Milling is a subtractive process for fabrication in which you begin with a solid block of your stock material and cut away at it to reveal your final desired object.CNC stands for computerized numerical controlled, and together CNC milling defines a computer-controlled method in which you can model your object using specialized software and send it to a machine that cuts .Fadal Engineering offers CNC machining centers, boring machines, and milling machines through an extensive network of North American dealers. 844.323.2526 AboutA CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such .

Top 10 Best CNC Machine Manufacturers & Brands in the World What is CNC Machine? A CNC machine is an automatic power tool with computer controlled for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. A CNC machine works with CAD/CAM software and G code for automated . The 14″ Sherline CNC mill has a 2.75″ (70 mm) x 13.0″ (330 mm) table. Note that the travel length on X-axis is 8.65″, 7″ on Y-axis, and 5.38″ on Z-axis. This actually determines how big a piece you can mill on this benchtop CNC machine. The weight of this mill is 40 lb., which means you can easily carry it around.DATRON high-speed CNC machines produce precision, complex parts that are burr-free and surgically clean in a fraction of the time. These compact CNC milling systems use very little floor space relative to their large machining area, require less power than traditional machines, and can be customized to meet your exact needs.

The Downsides of Using CNC Milling. CNC milling can be used to create parts from a wide array of materials, including metals, plastics and elastomers, ceramics, and composites. Because of this, CNC milling is a .The CNC mill is still one of the most common ways to manufacture metal parts. The most common CNC milling machines are the vertical machining center and horizontal machining center.Types of vertical and horizontal CNC machining centers range from 3-axis benchtop CNC mills to 5 axis CNC mills, short to long travels, and fast to heavy-duty RPM spindle speeds. This minimizes waste, increases accuracy, and contributes to better CNC machining dimensional tolerances that improve long-term performance. Acrylic can be cut using CNC mills or CNC lathes. CNC lathes are generally .

GEN MILL series multi-axis vertical machining centers, VMC, and CNC milling machines can produce high-volume precision shop productivity. ABOUT. Racing; PRODUCTS. GEN MILL SERIES. GEN MILL T-500; GEN MILL T-700; GEN MILL 5X-12; GEN MILL 5X-24; GEN MILL 2416; GEN MILL 2818;The Haas Desktop Mill is the ultimate training machine for schools and technical colleges. Powered by a full-function Haas CNC control housed in our portable simulator enclosure, the Desktop Mill is perfect for teaching the basic principles of programming and operating a CNC mill. Designed to cut plastics and machinable wax, it is also perfect .Multi-axis CNC machining centers come in three variations: 5-axis indexed CNC milling, continuous 5-axis CNC milling and mill-turning centers with live tooling. These systems are essentially milling machines or lathes enhanced with additional degrees of freedom. For example, 5-axis CNC milling centers allow the rotation of the machine bed or .

Peter Jacobs is the Senior Director of Marketing at CNC Masters, a leading supplier of CNC mills, milling machines, and CNC lathes. He is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in .

The machine part count is greatly reduced compared to traditional CNC machines, which both increases rigidity and decreases cost. GG3-S employs a horizontal milling format, a 9,000 rpm ER-11 collet unibody machined spindle and has a machinable area of 9.52" x 3.50" x 3.11", optimized for machining AR-15 and AK-47 receivers.

In this post, we will examine graphite’s material properties, key CNC machining techniques, and tips for properly selecting cutting tools for graphite. Grappling With Graphite: A Machining Guide . These coatings are grown directly into the carbide end mill, improving the hardness and leaving the tool with a coating layer that is 5 times . CNC machining is a manufacturing process in which a computer directs machines using programming codes to make a product. CNC (Computer Numerical Control) machining is a subtractive manufacturing process. This means that the computer program directs these tools (for example, drills, mills, and lathes) to constantly chip away at a workpiece.

While CNC machines are more expensive than manually operated and staffed machines, the ability to manufacture products over three shifts without needing to schedule three staff shifts returns more value on the purchase of the CNC machine than of a manual mill. The CNC machinist/engineer can also create “virtual prototypes” by using computer .CNC Machining is a very broad subject and there are many ways to do most things. Covering all options . and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks. This economy of instruction makes CNC accessible to almost anyone: from working engineers to students .Shell Mill Bodies; Milling Inserts; End Mills; Chamfer Mills & Inserts; Indexable End Mill Bodies; Ball End Mills; Chamfer End Mills; Roughing End Mills; . The World’s Most Popular CNC Mills. VF Series. Small VF Series; Medium VF Series; Large VF Series; Videos; Build-&-Price Recently Updated A Wide Range of Sizes and Features to Fit Any .

cnc milling machine near me

cnc milling machine for metal

Water-based metal paints are ideally suited to indoor items such as metal bedframes and wall-brackets. With so many different products on the market, choosing the best spray paint for metal can be an overwhelming task.

cnc machining mill|best home cnc milling machine