how to mig weld auto sheet metal Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success. Custom online sheet metal fabrication services, prototypes, and formed parts in aluminum, copper, brass, steel, and stainless steel. Instant online fabrication quotes, engineering feedback, and free shipping on all US sheet metal forming orders.

0 · welding sheet metal without warping

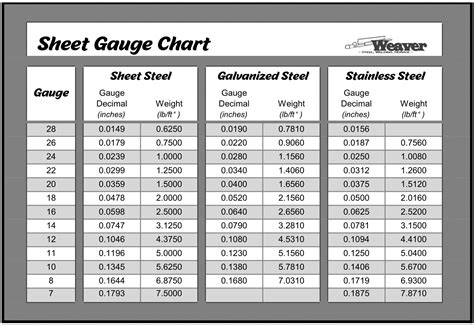

1 · welding 24 gauge sheet metal

2 · welding 22 gauge sheet metal

3 · welding 16 gauge sheet metal

4 · welding 14 gauge sheet metal

5 · mig welding thin sheet metal

6 · mig welding sheet metal basics

7 · mig welding automotive sheet metal

Wholesale Cabinet Hardware. Buy discounted kitchen cabinet hardware in bulk through Knobdepot’s trade reward program for builders, contractors, kitchen cabinet manufacturers, and retailers. View Selection Here.

welding sheet metal without warping

Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how very easy it is to start. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

welding 24 gauge sheet metal

MIG Welding Automotive SheetmetalThis clip from howtoASAP.com is from a 52 minute video featuring nationally recognized automotive builder, Craig Hopkins.

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

Today we are going to be welding thin sheet metal to replace old rusted out metal on our 1951 Chevy Panel van.

Here's some tips if you're having trouble mig welding thin sheet metal. Check out my custom mini parts available:Urchfab Front Subframe Kit: https://www.ebay. You'll never warp another panel again after watching this video. This is a realtime, step by step demonstration that shows how to mig weld sheet metal withou.

This is MIG welding, MIG standing for Metal Inert Gas. The gas is used to shield the molten puddle from the atmosphere and provide a clean environment for your weld. . Auto darkening masks have a solar panel that helps keep the batteries charged when exposed to the flash of a weld. Those four LED looking things are the light sensors, which .

welding 22 gauge sheet metal

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. How To Weld Sheet Metal The RIGHT WAY - SUPER EASY#howto #diy #welding My Friend Pete shows us the easiest and simplest way to weld sheet metal. From butt w. I keep blowing through my thin sheet! Andy gives helpful insights and tips to MIG weld thin sheet metal.KINGMETALS.com On this episode of Make It Kustom, I continue to repair the rust on the GMC G10 boogie van. We talk in depth about technique for repairing rust and welding o.

MIG welders are best recommended for these applications as MIG welding is the most common procedure used by people who make and work with sheet metal. Is it possible to stick weld sheet metal? Yes, you can stick weld sheet metal less than ⅛’’ thick, but you will need the right machine and a good set of welding skills to get the job done.MIG welding is the preferred method for most automotive bodywork, and since sheet metal is the thinnest of metals, a large, expensive MIG unit is usually not required.. The majority of sheet metal repair that I've done was with a 90-amp, 110-volt welder. There's nothing wrong with using a larger machine, it's just not necessary when welding thin metal.An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

HOBART HANDLER 140 WELDER - http://amzn.to/2vS6EQLWELDING VICE GRIPS - http://amzn.to/2vSpsj2HOBART .025 WELDING WIRE - http://amzn.to/2uAdPNNAUTODARKENING W.

It’s easier for me to tack in place with the Mig, then gas weld. I have a 3-1 machine that has Tig, I’m just not good enough to use it on light gauge metal. With a O/A I can come “in and out” and control things. My 3-1 doesn’t have a foot pedal so I . On this episode of make a custom I pull the 81 G10 Van in for a rust repair patch step-by-step mig welding.Check out how to make your own tucking fork here:h. Mig Welding Automotive SheetmetalThis clip from howtoASAP.com is from a 52 minute instructional DVD shot in HD featuring nationally recognized automotive bui. Eastwood Co makes a great low cost Flux Core welder that can MIG weld with a future purchase of a gas regulator, hose, appropriate MIG wire, and gas tank. . What you’ll find with sheet metal automotive welding you’ll .

This all occurs at about 100 to 150 cycles/second, and produces the famously characteristic frying egg sound that is associated with MIG welding. The most-often botched aspect of MIG welding is fit-up, the distance between . Wondering if it's possible to butt weld automotive sheet metal with a flux core welder? This video can help answer that question by using a Harbor Freig.

And it becomes even harder with the MIG welder. Thus, many welders suggest novice welders bypass MIG welding for sheet metals at first. But we are here with you with the best tips on welding sheet metal with a MIG welder. These tricks and tips would make MIG welding of thin sheets easy, smooth, and swift. Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. MIG Welding (GMAW) MIG welding works fine for thin materials . However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels. The panels’ aluminum’s chemical properties also require high voltage and wire feed speed settings to match the appropriate mode of metal .For MIG welding sheet metal, it is often recommended to use an electrode wire of the smallest diameter to prevent burn-through and warping. The main reason to use a smaller diameter wire is that it takes less heat for melting and hence the metal around the weld is not heated to a very great extent. This enables you to take control over the .

ds sheet metal

Thanks for Watching!!!High PSI tv Merchandise Available Below:http://highpsitv.bigcartel.comHelp me get to 100,000 Subs. Yea I know its a big number.Set your.

Enter the world of Flux Core Welding (FCW), a versatile technique with a unique approach to fusing materials.This method revolutionizes how welders approach sheet metal, from automotive repairs to constructing metal artworks.Grasping the principles of Flux Core Welding is essential for anyone interested in mastering this skill to achieve strong, durable, and reliable .Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

On this episode of Make It Kustom, I finish patching Kristina’s fenders for her body dropped 1960 Cadillac. We show you step-by-step how these panels are mad.

welding 16 gauge sheet metal

welding 14 gauge sheet metal

mig welding thin sheet metal

Discover our extensive range of affordable aftermarket CNC replacement parts, designed to keep your machines operating at peak performance. Our high-quality components ensure reliability and longevity, offering a cost-effective .

how to mig weld auto sheet metal|welding 14 gauge sheet metal