what is a cnc machines CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or . You should not use metal-sheathed or "BX" wiring with plastic electrical boxes. The reasoning is simple -- with armored cable, the box itself provides ground conductor continuity. Plastic boxes don't use metal cable clamps and do not provide the required grounding path.

0 · what is cnc machine definition

1 · how does a cnc machine work

2 · cnc machine used for

3 · cnc machine types and names

4 · cnc machine meaning in english

5 · cnc machine acronym

6 · cnc basics for beginners

7 · basic knowledge of cnc machine

Your best situation is when each room in the home has its own wire run to the dish or to the cable box on the outside of the house. You can use distribution amplifiers to boost signal in homes with many splitters and poor wiring. You can also choose to remove your dish or keep it installed.

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, . A machine tool equipped with a program control system is referred to as a Computer Numerical Control (CNC) machine. The control system processes relevant .A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

CNC machines, short for Computer Numerical Control machines, are a manufacturing technology that utilizes a computer program and automated tools to perform subtractive manufacturing processes. Unlike 3D printers that . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the . CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a .

A CNC (Computer Numerical Control) machine is a piece of equipment that uses computer-controlled software to automate machining processes. They are used to cut, drill, .

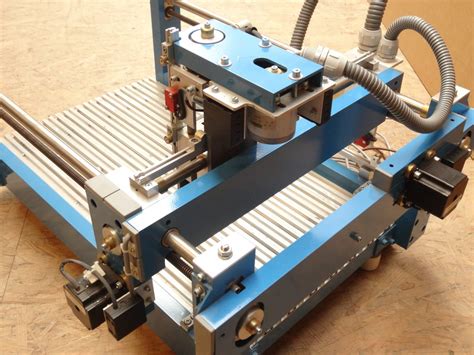

A CNC machine at the most basic level is nothing more than a computer controlled machine. CNC is an acronym for Computer Numerical Control. You can read more about Numerical Control here. Typically when . A CNC machine, also known as a Computer Numerical Control machine, is a manufacturing technology that uses a computer program to control the movement of specialized tools in subtractive manufacturing processes. CNC machines also come in a variety of sizes, from small desktop CNC machines like tabletop mills or benchtop routers to heavy-duty, large horizontal machining centers. Let’s examine these machines individually to . The input devices are used to input the program into the CNC machine tools. There are usually three common input devices; punch tape reader, magnetic tape reader, and computer via an RS-232-C communication channel. 3. Machine Tool. CNC machine tools always come with a slide table and spindle to control the speed and position.

#cncmachining In this video, you’re going to learn what CNC machining is and how it works. After watching you will have a good understanding of CNC machining. CNC Machining Is Fully Automated. In today’s CNC protocols, the production of parts via pre-programmed software is mostly automated. The dimensions for a given part are set into place with computer-aided design (CAD) software and then converted into an actual finished product with computer-aided manufacturing (CAM) software. CNC machines automate many tasks but still require skilled operators and programmers. Rather than replacing workers, they are transforming the nature of manufacturing jobs. Can I use a CNC machine for small-scale or hobby projects? Yes, there are many desktop CNC machines designed for hobbyists and small businesses.What is a CNC Machine? CNC machines can be defined as machine tools that are automatically controlled using a computer. CNC machine processes a piece of material like metal, plastic, wood, ceramic, or composite to meet the spec of a coded programmed instruction without a manual operator.

What Is a CNC Machine? CNC stands for computer numerical control; it is a process that allows for tool automation. While people may believe that CNC machinery is a small, bespoke set of automated machines, in reality, the CNC designation stretches across many different kinds of computer numerically controlled machine tools.

what is cnc machine definition

how does a cnc machine work

cnc machine in hindi, working of cnc machine, what is cnc machine, cnc machine components👉MTS के Pdf Notes के लिए इस वीडियो को देखें-Click here .

CNC machine tools can be classified based on their motion tracks into three categories: point-controlled, straight-line controlled, and contour controlled. (1) Point control CNC machine tool. Positioning control, also known as Point-to-Point Control, is a technique used to precisely position moving parts from one position to another.

CNC machines can even be applied in the electrical industry, woodworking industries, lettering and engraving systems, the pharmaceutical industry, the beverage and food industry, and much more. Whatever manufacturing business you are in, you will undoubtedly find some CNC machine that suits your requirements.

A CNC machine is designated 5-axis when it is capable of three directions of movement for the cutting tool — the X, Y, and Z axes — and rotational movement for the cutting tool around the X-axis and Y-axis, which are referred to as the A-axis, and B-axis, respectively. What Is a Machining Center?

CNC machine tool is composed of a spindle, tool changer (tool holder and tool magazine manipulator), ball screw, and other functional components. Most of the machine tool companies through outsourcing and outsourcing of different functional components and combined assembly, build a complete machine tool. .CNC drilling machines are commonly used to automate this job, and provide better accuracy and a more cost-effective solution. Types of CNC Machines. As said before, CNC machines are not limited to the traditional sense of CNC . cnc machining Understanding the Basics of CNC Machining. At its core, CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece, creating a desired shape or design. Reasonably determine the functions of CNC machine tools. When selecting the features of CNC machine tools, it’s important not to prioritize a large number of functions or excessive specifications. Having too many coordinate .

The origins of CNC machines can be traced back to John Parsons. He is credited with creating the first numerical control machine in 1949, which was designed to run directly off a set of punch cards that told the machine where to move. The Cincinnati Milacron Hydrotel, the first commercially available CNC machine, was later introduced in 1952 by . CNC welding machines, also known as Computer Numerical Control welding machines, have revolutionized the world of welding. These high-tech machines offer automation, precision, and efficiency in the welding process.

CNC Machine is a machine with computer system which usually commands by the coded program to the physical machine for performing some cutting or shaping processes.. CNC stands for Computer Numerical Control.It came from NC- Numerical Control. From the 1940s the NC system has developed into a CNC system. In the 2020s, CNC is now one of the most used .The CNC machine comprises of the mini computer or the microcomputer that acts as the controller unit of the machine. While in the NC machine the program is fed into the punch cards, in CNC machines the program of instructions is fed directly into the computer via a small board similar to the traditional keyboard. In CNC machine the program is stored in the memory of the . A CNC machine is a more advanced version of an NC machine, which can be controlled via computer software (hence why it is called computer numerical control). While NC tools can still serve a purpose, they require more skill, time, and effort than a CNC machine.

Types of CNC Machines. CNC Mills. CNC mills use rotary cutting tools to cut material from the workpiece, enabling precise shaping and detailing. The control center interprets and implements specific instructions so the spindle moves to exact depths and locations. The versatile machine can process various materials including metals, plastics .What is a CNC Machine? CNC stands for “computer numerical control. ” These machines represent a manufacturing process used to control a wide range of complex tasks. CNC machining is used in many different industries. The Machine Control Unit (MCU) is the “brain” of your CNC machine. It reads the G-code and M-code and then sends signals to the machine’s motors. This ensures that the machine moves exactly how it’s supposed to.

CNC machine types have components that shape metal or other materials such as lathes, drilling machines, milling machines. In traditional methods, machines are used by expert operators. Therefore, the risk of errors in business processes is high. There are also high risks of accidents and injuries. Using work machines manually requires intense . CNC machines can be programmed to work with a wide range of materials, from metals and plastics to composites and ceramics, making them versatile across various industries.

cnc machine used for

cnc machine types and names

Welding sheet metal requires precision and expertise, with the choice of technique depending on the thickness of the metal. TIG welding uses a non-consumable tungsten electrode to produce clean and precise welds, while MIG welding is quicker and more efficient but can result in porosity if not done correctly.

what is a cnc machines|cnc machine used for