cnc machine torque When purchasing a CNC Machine for your job shop it's important to understand how the spindle, torque and power ratings work. Many machine tool builders hide the truth in . $10.99

0 · torque formula for cnc

1 · torque for cnc machine

2 · machining torque formula

3 · machining torque calculator

4 · how much torque for cnc

5 · cnc tool head torque

6 · cnc spindle torque calculator

7 · cnc machine spindle torque

Tungsten carbide, sometimes called carbide, is harder than Corrosion-Resistant Tungsten with excellent wear resistance. Use it to machine long-lasting tools, such as end mills and inserts. For technical drawings and 3-D models, click on a part number.

torque formula for cnc

metal stakes for bounce house

torque for cnc machine

The torque you need on a CNC machine is dependant on: 1) How much force the mill is expected to exert on the material 2) The resistance of the linear bearings used to move the axes 3) The type/style of cnc mill(i.e mills using a moving gantry need more torque than a xy table) 4) The .When looking around for motors, look at their datasheets which should contain a torque curve related to RPM (revolutions per minute). This is where this formula and applying it to the . When purchasing a CNC Machine for your job shop it's important to understand how the spindle, torque and power ratings work. Many machine tool builders hide the truth in .

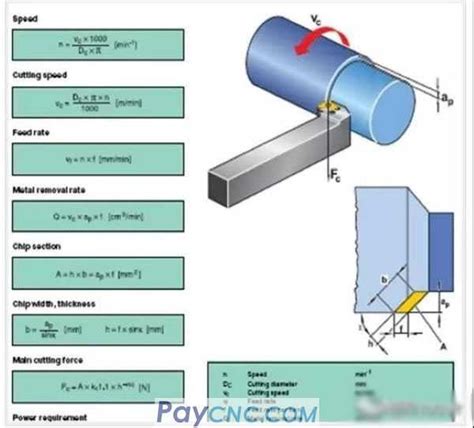

Learn how to read and use a spindle motor torque, power, and duration chart to optimize your machining processes on Tormach's 1500MX CNC mill. The formula for calculating torque is as follows. Md=1/20*f*ps*r2. f is the coefficient of feed mm/rev. r is the drill radius (mm) α: cutting resistance ratio ps. at small feed, general steel 500kg/m²; general cast iron 300kg/m². .This diagram shows how much power and torque are available at various spindle speeds. If you exceed the torque available, the motor will stall, just stop rotating. If you exceed the rated .

Two fundamental limitations on machining performance are the spindle motor’s available torque and power. The specifications of the torque and power limitations are often available in torque and power curves from machine . You can think of torque as a tractor: It can’t go very fast, but there is a lot of power behind it. Think of horsepower as a racecar: It can go very fast but cannot pull or push. Torque-Horsepower Chart. Every machine and .

metal stamping houses

Your motors must produce enough torque to accelerate the axis quickly enough to reach your machine's target speeds in a reasonably short distance. I've written some detailed articles . P98 = Performs a skip operation if the torque of the servo motor reaches the limit value. P99 = Performs a skip operation if the torque of the servo motor reaches the limit value or if a skip signal is input. G31 is a one shot G Code, and its likely to be used for Torque Limit Skip with a Grinding Machine when plunge grinding.This machine tool has one Z-axis and one CNC axis; The main shaft and gearbox have been specially optimized. Designed for drilling with high torque and axial force. We can provide various processes such as drilling, boring, expanding, reaming, and internal threading. Rough and precision machining are the preferred integrated solution for fast .*Haas machines are designed to operate on 220 VAC (200-240 VAC) power. An optional internal high-voltage transformer (380 - 480 VAC) is available for all models, except the Desktop Machines, CL-1, CM-1, and SR Series routers. .

Roughing operations can push a CNC machine to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits. . For many operators, consulting the horsepower and torque charts is an exception rather than a habit, Ward says. In part, this is because many CAM systems automate this calculation. Help.. I have a Makino RMC 55 with Fanuc Om. The spindle at low rpm has little/no torque. If the motor is set at 100rpm you can drag your finger on the spindle and stop it without much pressure. The motor will then make a couple high . This sums up the real issue. Running manual machines before you run a CNC is highly valuable as a training aid. Manual machines provides far more feedback during the cutting process vs proclaiming, 'It worked!' when the CNC finishes a part. If you have no manual machine experience before running a CNC, it helps to use a torque wrench to learn to tighten shit down .

We have a new machining coming in replacing our haas. The new machine has a 40HP Cat40 Direct Drive 2 Speed 15k Spindle, The haas had a 15k 30hp spindle. After comparing torque charts, the haas looks like in only has about 5-8 ft lbs lower thru the curve than the new machine. To me this seems crazy as honestly the 30hp haas spindle had no balls.

Torque Wrench Basics - Haas Automation, Inc. This video provides an introduction to using click-type torque wrenches. Most of this will be quite familiar if you've been using a torque wrench for a while. But if you have someone in your shop that hasn't been introduced to torque wrenches yet this video might be helpful.

Pull stud torque values probably vary from machine to machine? Should they vary depending on how much force will be applied to the cutting tool? Should I tighten a 40 taper drawbar the same amount? . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most .

*Haas machines are designed to operate on 220 VAC (200-240 VAC) power. An optional internal high-voltage transformer (380 - 480 VAC) is available for all models, except the Desktop Machines, CL-1, CM-1, and SR Series routers. This optional high-voltage internal transformer is not field installable; it must be ordered with the machine. ATTENTION!

When no torque limit command is issued in the torque limit skip command in the PMC or other windows, alarm PS0035 is issued. When no toque limit command is issued, the torque limit override value is either 0% or 100%. The torque limit command is issued as shown in the following programming example. (Program example) O0012 ; :Gotcha. AC motor, or BLDC? AC motors have a defined torque vs freq curve, generally full torque up to 60Hz running off a VFD. BLDC torque is linear, falls with rpm. Generally even with carbide if you're cutting steel a 3/4 mill won't run past say 4k. Faster than that you're typically running small tools where torque isn't important. CNC Machining . Torque of CNC vs Turret mill. Thread starter Tim in D; Start date Apr 11, 2007; Replies 2 Views 1,054 . Its just the difference in a constant hp machine versus a constant torque one. Of course, you can take the current 20hp machine, thread mill the hole, get on with the rest of the operations, and likely complete 2 or more .Select the Right Chuck Jaws & Torque Them Correctly! - Haas Automation TOD Toolbox. Selecting chuck jaws and fastening them to our chucks might seem too simple a process to even be worth considering.

I dicked around with the torque skip on mine and realized I don't trust anything Kia pushes. I tried that on some 17-4 PH and found the spring loaded live center was the way to go. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for .

CNC Machining . High Speed vs High Torque. Thread starter ultraguy; Start date Dec 28, 2021; Replies 14 Views 3,715 U . And I almost never even go above the max speed of the high-torque machine IN the high-speed machine so it’s kind of a waste for me.if I could trade the high speed for a high torque I would. . You want the torque high enough that the thread tension from it is higher than the tension from the drawbar, so the joint with the top of the taper shank doesn't unseat. Also, with high torque, a defective thread will likely break during torquing, rather than during operation. Same for your car wheel studs. had a machine where machine alignment seemed off and every time checked it measured perfect. i bolted on precision level and saw level change every minute. parts were bending under load as most parts do and alignment changed when machine was running under load. the Swiss kept saying machine was perfect. the precision level bolted on was saying .

5000 RPM is SLOW for machining aluminum. The torque you need for machining steel is quite substantial. Assuming you plan to gear the motor properly to make best use of available torque, healthy cuts in steel with a 1/2 cutter will need at least a few KW. Matt In many CNC machine tools, the main motor drives the spindle via a belt, which is one of the most common applications for belt drives. . High torque transmission: gear transmission can effectively transmit high torque and is suitable for various machining scenarios. Adaptable: able to adapt to variable speeds and variable loads. Disadvantages .

I've taken to using a torque wrench tightening chuck jaws and mount bolts. The M12 get 84 LB-FT on my lathe. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn .

The torque is good in low range aprox. 250 ft lbs and it will push a 1.500 drill no problem. The milling performance is limited by chatter on larger tools and deeper cuts. The VMC 15 is not a heavy duty machine. My sugestion would be to make new poly chain pulleys at a 1-2 ratio. 3500 rpm top speed and about 2x the torque of a standard machine.

The Importance of Proper Torque in a Collet Chuck Tool Holding System – Techniks CNC Tooling Solutions. This article discusses on the importance of proper torque when setting up a collet chuck tool holder and how using a torque wrench helps ensures consistency across tool changes.

I did already have the torque skip and IF statement verification working on this machine, and just added this chip break peck to alleviate a chip buildup issue that causes problems occasionally. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited . 173 foot pounds of torque sounds good. so maybe its more torque then hp. I know that my machine has a high speed spindle option. it goes up to 15,000 rpm. But the max torque rating is 205 Nm. And with the normal (8,000 rpm) spindle it is 235 Nm So maybe thats the difference. thanks again For torque specifications on balllscrew components refer to Ballscrew - Installation Tools and Torque Specifications. For torque specifications on the main circuit breaker hardware refer to Haas Main CIrcuit Breaker - Torque Specifications. For torque specifications on the double arms refer to the SMTC - Double Arm - Replacement procedure.

Hi all, I have a lathe and I get alarm SV0409 Detect Abnormal Torque (X). I changed the end bearings but still I have same alarm. I get alarm in rapid and if I change from 25% to 50% or 100% the alarm does not appear, after couple of minutes I get again same alarm.

Setting the IP address. The IP address can be set using four different procedures, and these will be described in more detail below. BX9000: The addressing method is specified via a .

cnc machine torque|torque formula for cnc