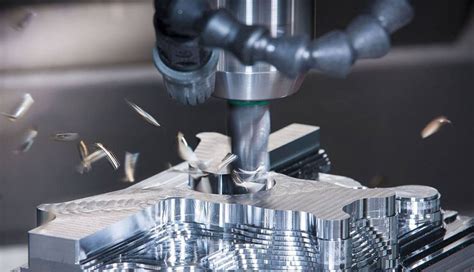

cavity machining of aluminum alloy precision non-standard parts Choose the right feed speed, spindle speed, and cutting depth; Symmetrical machining for the front and back of the workpiece; Multi-layer machining for all cavities of the workpiece; Use . CRE offers a variety of high integrity dry and pressure compensated junction box designs to suit specific customer requirements. Essential on many system designs to deliver a simpler and more reliable solution for electrical or fibre optic functionality, reducing down time and operating costs.

0 · what is aluminum machining

1 · machinability of aluminum steel

2 · machinability of aluminum alloys

3 · cnc aluminum machining

$89.99

Products from casting to precision machining require strict quality control, with complex and variable processes, often resulting in higher costs compared to standard parts. .

Understanding and optimising these parameters can lead to improving the machinability, better surface finish, longer tool life, and overall, more efficient and cost-effective . This review article is focused on the study of machining characteristics of aluminum alloys, such as machinability, surface integrity, tool wear and tool life, material .Choose the right feed speed, spindle speed, and cutting depth; Symmetrical machining for the front and back of the workpiece; Multi-layer machining for all cavities of the workpiece; Use . Products from casting to precision machining require strict quality control, with complex and variable processes, often resulting in higher costs compared to standard parts. Non-standard parts are indispensable in modern industry.

Understanding and optimising these parameters can lead to improving the machinability, better surface finish, longer tool life, and overall, more efficient and cost-effective machining processes for wrought aluminium alloys.

This review article is focused on the study of machining characteristics of aluminum alloys, such as machinability, surface integrity, tool wear and tool life, material removal rate (MRR), and chip morphology.Choose the right feed speed, spindle speed, and cutting depth; Symmetrical machining for the front and back of the workpiece; Multi-layer machining for all cavities of the workpiece; Use drilling and then milling when machining parts with a cavity.

gm modular metal box

what is aluminum machining

At present, the main processing materials for thin-walled parts are aluminum alloy, titanium alloy or nickel alloy, and some composite materials. The process of changing the size or function of the workpiece is called non-standard parts. Cold working and hot working are divided according to the temperature conditions of the workpiece. With lower density and hardness than copper or steel and greater malleability, aluminum CNC machining can achieve higher feed rates and increased manufacturing productivity. There are several key considerations can make or break the success of a project. This paper therefore provides an overview of the classes of aluminium alloys, there applications and machining of the alloys with a keen focus on 6061 aluminium alloy and exposition of various.

For aluminum parts with large machining allowances, excessive heat concentration must be avoided to produce better heat dissipation and reduce thermal deformation. Symmetrical machining can prevent excessive heat build-up around parts during machining. For the low stiffness of thin-walled parts, high-speed milling provides an efficient approach for machining the aviation aluminium-alloy thin-walled parts with high quality and high efficiency, and the machining parameters directly affect the machining quality.

Products from casting to precision machining require strict quality control, with complex and variable processes, often resulting in higher costs compared to standard parts. Non-standard parts are indispensable in modern industry. Understanding and optimising these parameters can lead to improving the machinability, better surface finish, longer tool life, and overall, more efficient and cost-effective machining processes for wrought aluminium alloys.

This review article is focused on the study of machining characteristics of aluminum alloys, such as machinability, surface integrity, tool wear and tool life, material removal rate (MRR), and chip morphology.Choose the right feed speed, spindle speed, and cutting depth; Symmetrical machining for the front and back of the workpiece; Multi-layer machining for all cavities of the workpiece; Use drilling and then milling when machining parts with a cavity.

At present, the main processing materials for thin-walled parts are aluminum alloy, titanium alloy or nickel alloy, and some composite materials. The process of changing the size or function of the workpiece is called non-standard parts. Cold working and hot working are divided according to the temperature conditions of the workpiece. With lower density and hardness than copper or steel and greater malleability, aluminum CNC machining can achieve higher feed rates and increased manufacturing productivity. There are several key considerations can make or break the success of a project.

This paper therefore provides an overview of the classes of aluminium alloys, there applications and machining of the alloys with a keen focus on 6061 aluminium alloy and exposition of various. For aluminum parts with large machining allowances, excessive heat concentration must be avoided to produce better heat dissipation and reduce thermal deformation. Symmetrical machining can prevent excessive heat build-up around parts during machining.

glue fabric to metal washable

machinability of aluminum steel

gm 1.4l thermostat housing replacement metal

machinability of aluminum alloys

$16.69

cavity machining of aluminum alloy precision non-standard parts|cnc aluminum machining