deburr sheet metal parts Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are . $16.98

0 · sheet metal deburring parts

1 · how to remove burrs from metal

2 · how to deburring metal

3 · deburring tool

4 · deburring process

5 · deburring blocks

6 · deburring block for metal

7 · chemical deburring tool

Yes, metal fabrication is an excellent career path. There are many different paths you can take in this field, be it in construction, heavy machinery operation, or studying metallurgy. Many of these careers don’t require a college degree, allowing you to get started on your career path right away.

Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and .

In the following article, you will learn the advantages of deburring sheet metal .Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are .A Ultimate Guide to Sheet Metal Deburring, Its Methods, and Its Applications. Deburring of sheet metal is one of the essential requirements in the manufacturing process. Here the parts or .There are a number of ways to remove sharp edges and burrs quickly and affordably from metal parts, including vibratory finishing and barrel tumbling. Here, you’ll get an overview of 5 common deburring methods to help you determine .

In the context of metal manufacturing, a burr refers to the formation of rough edges or ridges on the metal piece. The reason behind it lies in the manufacturing process and the tools involved in its production. It is especially .In the following article, you will learn the advantages of deburring sheet metal parts and how to increase operating efficiency with the help of state-of-the-art machines. Whether punching, .

sheet metal deburring parts

What are the different methods of sheet metal deburring? Manual deburring; Punch deburring; Brushing; Electromechanical deburring; Thermal energy deburring; Vibratory finishing; Sheet metals are used across several industries .One of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over what causes burrs to form, why removing them is so critical, and what . Deburring machines offer an efficient and precise solution for removing sharp edges and burrs from small sheet metal parts. Automated deburring machines are particularly well-suited for handling high volumes of .

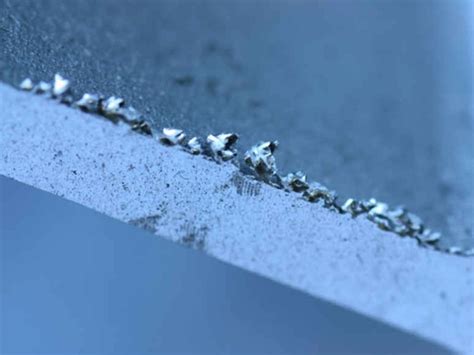

Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are tiny pieces of metal typically stuck to the edges.Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are tiny pieces of metal typically stuck to the edges. Deburring, the process of removing unwanted burrs or sharp edges from metal parts, can be effectively accomplished using a punch mold in a punching machine. This method leverages the precision and efficiency of punching dies to achieve high-quality deburring results.A Ultimate Guide to Sheet Metal Deburring, Its Methods, and Its Applications. Deburring of sheet metal is one of the essential requirements in the manufacturing process. Here the parts or tools are made free from burrs or sharp edges.

There are a number of ways to remove sharp edges and burrs quickly and affordably from metal parts, including vibratory finishing and barrel tumbling. Here, you’ll get an overview of 5 common deburring methods to help you determine the best deburring process for your metal parts.

In the context of metal manufacturing, a burr refers to the formation of rough edges or ridges on the metal piece. The reason behind it lies in the manufacturing process and the tools involved in its production. It is especially common with cutting operations on sheet metal.In the following article, you will learn the advantages of deburring sheet metal parts and how to increase operating efficiency with the help of state-of-the-art machines. Whether punching, laser cutting or plasma cutting: Processing sheet metal produces sharp edges and burrs.What are the different methods of sheet metal deburring? Manual deburring; Punch deburring; Brushing; Electromechanical deburring; Thermal energy deburring; Vibratory finishing; Sheet metals are used across several industries for a wide variety of workable parts. However, processed sheet metals may not always be in the best conditions.One of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods .

Deburring machines offer an efficient and precise solution for removing sharp edges and burrs from small sheet metal parts. Automated deburring machines are particularly well-suited for handling high volumes of parts, providing consistent and uniform results.Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are tiny pieces of metal typically stuck to the edges.

Deburr metal parts, sheets and plates double or single-sided. Save valuable time and money with the optimal deburring solution. Deburring of sheet metal is the removal of protruding metal and sharp edges after cutting. These burrs are tiny pieces of metal typically stuck to the edges. Deburring, the process of removing unwanted burrs or sharp edges from metal parts, can be effectively accomplished using a punch mold in a punching machine. This method leverages the precision and efficiency of punching dies to achieve high-quality deburring results.A Ultimate Guide to Sheet Metal Deburring, Its Methods, and Its Applications. Deburring of sheet metal is one of the essential requirements in the manufacturing process. Here the parts or tools are made free from burrs or sharp edges.There are a number of ways to remove sharp edges and burrs quickly and affordably from metal parts, including vibratory finishing and barrel tumbling. Here, you’ll get an overview of 5 common deburring methods to help you determine the best deburring process for your metal parts.

In the context of metal manufacturing, a burr refers to the formation of rough edges or ridges on the metal piece. The reason behind it lies in the manufacturing process and the tools involved in its production. It is especially common with cutting operations on sheet metal.

In the following article, you will learn the advantages of deburring sheet metal parts and how to increase operating efficiency with the help of state-of-the-art machines. Whether punching, laser cutting or plasma cutting: Processing sheet metal produces sharp edges and burrs.What are the different methods of sheet metal deburring? Manual deburring; Punch deburring; Brushing; Electromechanical deburring; Thermal energy deburring; Vibratory finishing; Sheet metals are used across several industries for a wide variety of workable parts. However, processed sheet metals may not always be in the best conditions.

One of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods .

how to remove burrs from metal

Type of Brackets. TenRal can make many types of sheet metal brackets. These range from simple to complex and from standard to custom designs. L-shaped bracket: This bracket has an “L” shape. People often use it to connect a wall to a horizontal surface.

deburr sheet metal parts|chemical deburring tool