galvanic corrosion danger electrical box When dissimilar metal alloys come into contact in the presence of moisture or humidity in electrical systems, galvanic corrosion can occur. This corrosion compromises the functionality and lifespan of electronic .

We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and medium run metal parts faster than the competitor because of our in-house tooling system .

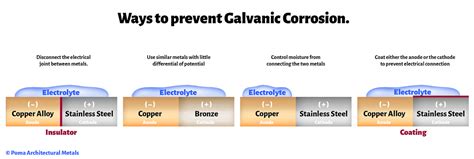

0 · how to prevent galvanic corrosion

1 · galvanized metal corrosion

2 · galvanic corrosion temperature

3 · galvanic corrosion resistance

4 · galvanic corrosion reaction

5 · galvanic corrosion chart

6 · galvanic corrosion causes

7 · corrosion on electrical panels

The manufacturing process in wholesale sheet metal drawing auto part factories involves several steps. It begins with the initial design, where experts create detailed drawings and models .

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. Galvanic corrosion, also known as bimetallic corrosion or dissimilar metal corrosion, is an electrochemical process that occurs when two different metals are in contact with each other in the presence of an . Galvanic corrosion is an electrochemical process where the use of two dissimilar metals in the presence of an electrolyte causes one metal to corrode over the other it is paired with. Galvanic corrosion can significantly affect the lifespan and integrity of metal structures, especially in marine or humid environments. It's essential to understand the metals .

Galvanic corrosion is a problem when the two metals are wet or damp , water being necessary to conduct current causing corrosion. In some conditions of humidity and . When dissimilar metal alloys come into contact in the presence of moisture or humidity in electrical systems, galvanic corrosion can occur. This corrosion compromises the functionality and lifespan of electronic . Galvanic corrosion, also known as bimetallic corrosion, is a type of corrosion that affects metal. It occurs when two dissimilar metals are either in direct contact or electrically connected and immersed in an electrolyte. Galvanic corrosion (also called ' dissimilar metal corrosion' or wrongly 'electrolysis') refers to corrosion damage induced when two dissimilar materials are coupled in a corrosive .

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Galvanic corrosion is a phenomenon that occurs when two dissimilar metals are in direct electrical contact and are also exposed to an electrolyte, such as water or saline solution.

how to prevent galvanic corrosion

G71 Guide for Conducting and Evaluating Galvanic Corro-sion Tests in Electrolytes G82 Guide for Development and Use of a Galvanic Series for Predicting Galvanic Corrosion Performance G102 Practice for Calculation of Corrosion Rates and Re-lated Information from Electrochemical Measurements G215 Guide for Electrode Potential Measurement 3. The condition of the corrosion protection arrangement of the specific box cooler and sea chest. If new coating is applied, do not coat the tube bundle, anodes or cathodes, as applicable. A small area of damaged coating in the sea chest will concentrate galvanic corrosion to the area of exposed steel. Based on what I know and on your stated use a hull bond is vital for safety and to minimise the danger this brings from galvanic corrosion use a modern GI with monitoring built in. Otherwise the only way to be as sure as . Apparently galvanic isolators can’t help with more than about 1.5 volts, and the Marinco tech suggested that Gizmo’s 10 year old isolator should be checked anyway. (I found some instructions at the Yandina site.) Of course another shore power danger to worry about is plug corrosion causing resistance, which then causes a boat fire.

An examination of field notes from more than a thousand private home inspections performed between 1987 and 1991 reveals rust and corrosion of various electrical components in 126 of 1052 service panels.What type of electrical diagram are images instead of components used? Block diagram. Schematic diagram. . Galvanic corrosion is likely to be most rapid and severe when. . Fayed surfaces cause concern in chemical cleaning because of the danger of. Choose matching definition. entrapping corrosive materials. forming passive oxides.

Explanation: Battery is a combination of cells in which chemical energy is converted into electrical energy. Carbon (noble electrode) acts as cathode and zinc (active electrode) acts as an anode. . This metal combination results in little danger of galvanic corrosion. Example: [ Monel, bronzes, copper, brasses] 13. The potential generated by .They utilize galvanic isolation to separate shore power from onboard power, thereby eliminating stray AC currents and preventing galvanic corrosion of metal parts in the electrical system. Isolation transformers can be built using traditional transformers or toroidal transformers for isolation and are encased in solid epoxy resin to protect . The system is inside a box with a lid and a cooler installed. relay; Share. Cite. Follow edited Feb 2, 2022 at 20:24. JulioC1427. asked Jan 31 . $\begingroup$ Looks like accelerated galvanic corrosion to me. $\endgroup$ – jonk. Commented Feb 1, 2022 at 5:13 . Thanks for contributing an answer to Electrical Engineering Stack Exchange!

Either (or both) metal in the couple may or may not corrode by itself (themselves). When contact with a dissimilar metal is made, however, the self corrosion rates will change: corrosion of the anode will accelerate corrosion of the cathode will decelerate or even stop. Galvanic coupling is the foundation of many corrosion monitoring techniques. In order to explain the corrosion inside 20th century power lines, the galvanic corrosion of steel and aluminum from 1949 was examined. In this investigation, 0.1 M Na2SO4 + 1 mM NaCl was used as moderately corrosive medium. . Finally, the corrosion of steel regulates the corrosion of both metals when they are in electrical contact. Export .Environments for Galvanic Corrosion. Galvanic corrosion occurs when the following conditions exist: A direct contact between two dissimilar metals with different corrosion potentials, A conductive electrolyte solution, such as saltwater, connecting the two metals on a regular basis. If any of these conditions are not present, galvanic corrosion .

Anode Junction Box for Cathodic Protection . Farwest standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a Hoffman powder coated steel enclosure, a Micarta insulating panel, copper buss bar, shunts (customer . In this study, the effect of current flow through electrical parts on galvanic corrosion behavior was investigated. To predict the corrosion rate of galvanic coupled electrical parts, an equivalent circuit was constructed, encompassing both galvanic and external currents. Following the circuit, the corrosion current equation was formulated based on Kirchhoff’s law, .

galvanized metal corrosion

Galvanic corrosion, also known as bimetallic corrosion or dissimilar metal corrosion, is an electrochemical process that occurs when two different metals are in contact with each other in the presence of an .

2.1. Galvanic Corrosion. When a metal (M) comes into contact with aqueous electrolyte solutions, an electrochemical reaction called corrosion occurs at the interface, which leads to deterioration or degradation of the metal.The metal is oxidized, which means that the metal loses electrons and becomes a metallic ion (M z +).Galvanic corrosion occurs between .

Using Tef-Gel . Tef-Gel is an anti-corrosion and anti-seize lubricant that does a remarkable job at preventing contact between dissimilar metals. It is commonly applied to rivets on sailboat masts to prevent galvanic corrosion. . But you know you have problems as I have found (the hard way) when you get a shock from the housing of any electrical equipment you may have on board. I have been shocked from searchlights (was turned off) and Fathometer's housings (off or on). So you may have to check for leakage at each piece of electrical/electronic equipment you have on board.Electrolysis is a process that involves electrical current and the metal areas of your boat. This means that metal hull boats are far more susceptible to corrosion at the hands of electrolysis. . Galvanic corrosion is pure chemistry and does not require any electrical current to be present for it to occur. . PO Box 798 Snow Hill, NC 28580 . 2) SS RMC shall only be used with approved accessories, outlet boxes and enclosures #2 seems to suggest that the UL listings of "accessories", "outlet boxes" and "enclosures" should explicitly state "allowed to be attached to SS hardware" if there was a galvanic concern, then #1 alone makes no sense.

AVIONIC AND ELECTRICAL SYSTEM CORROSION PREVENTION AND CONTROL MAINTENANCE by G.T.Browne Material Advisor, COMNAVAIRLANT Norfolk, VA 23511-5188, USA. 1 A study of premature failures of installed avionics, electrical equipment, and systems experienced in US Fleet operational aircraft in the 1960s and early 1970s was reported in .

The bus bar visible in the empty slot appears to have a lot of white on it, and the tab where the breaker isn't shows a lot of corrosion. its not a good thing when aluminum bus bars and tabs look that way. there will be breakers overheating and burning up. the traces of corrosion the op was asking about weren't actually significant, but the box .Water or Moisture Sources Causing Rust and Corrosion in Electrical Panels . This page continues with details supporting . CORROSION in ELECTRICAL PANELS - Holm Conference Study.. Here we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report.corrosion product that forms when a galvanic cell is formed between copper and silver. Green plague is the reaction product of some resin-based solder fluxes with copper . Excessive corrosion can impair the wire's fatigue life and electrical conductivity. There is no wire conductor material that can be recommended as the panacea to Historical .

Electrical conductivity of the environment: Conductive environments, such as those with high mineral content, can worsen galvanic corrosion. Microbial activity: Certain microorganisms in soil or water can accelerate corrosion processes by promoting the formation of corrosive byproducts.Corrosion is a natural process that happens when metal or metal alloy surfaces come into contact with a corrosive fluid and form an oxide. Corrosion can occur slowly over time or can be accelerated by humidity, heat, salts, and acids, and other similar factors. Rust is the most common form of corrosion, and it can cause significant damage to equipment if left unchecked.

Corrosion prevention can also be achieved through the use of gold or silver plated contacts and terminals. Gold and silver are both noble metals, which mean that they are naturally resistant to oxidation and corrosion. (For more information about noble metals, see An Introduction to the Galvanic Series: Galvanic Compatibility and Corrosion .

galvanic corrosion temperature

galvanic corrosion resistance

Buy sheet metal parts in bulk online from 56 verified wholesale sheet metal parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources.

galvanic corrosion danger electrical box|corrosion on electrical panels