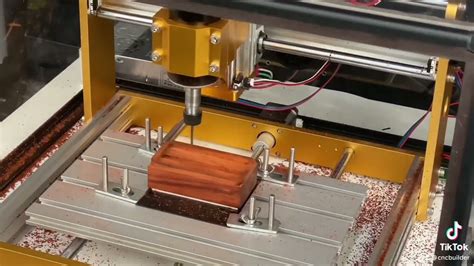

3018 cnc router parts Replacement X-Axis parts to fit the original NCPRO 1810-PRO, 3018-PRO and . We provide you with information on our distribution boxes for download. Download our product catalogue for sensor-actuator cabling and circular connectors or our portfolio overview for FieldPower® distribution boxes for .

0 · mostics cnc 3018 pro setup

1 · how to use 3018 cnc

2 · cnc 3018 software setup

3 · cnc 3018 pro specifications

4 · cnc 3018 pro software setup

5 · best router upgrade for 3018

6 · best 3018 cnc machine

7 · 3018 cnc engraver setup

You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge Size Chart PDF. (Click here) How many mm is 8 gauge? For different materials of steel, the same gauge will also correspond to different mm. What is 10 gauge in mm? What is 16 gauge thickness in mm?Below you will find a chart for metal thicknesses and weights. Commonly used metals for manufacturing at our shop are: Aluminum: 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 1/8" (0.125") and 1/4" (0.25"). Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". .

Desktop CNC Supply stocks a selection of genuine factory 3018 PRO replacement parts to repair your 1610/1810 and 3018 PRO CNC Desktop Router.We've got your X,Y and Z covered, with genuine NCPRO 3018-PRO Desktop .Replacement X-Axis parts to fit the original NCPRO 1810-PRO, 3018-PRO and .We stock an ever-increasing variety of desktop and bench-top CNC routers, .

mostics cnc 3018 pro setup

how to use 3018 cnc

Visit 3018nc.com for a wide variety of 3018-PRO Desktop CNC Z-AXIS .We stock an ever-increasing variety of desktop and bench-top CNC routers, linear motion components and replacement parts – to fit popular 3018 type CNC hobby routers and home-builds. And are the exclusive stockists of NCPRO dust .Replacement X-Axis parts to fit the original NCPRO 1810-PRO, 3018-PRO and 3018 MAX Desktop CNC Routers. These OEM parts will fit many other 1610, 1810 and 3018 CNC clones.

Aside from machine ridgidity, I'd check to see if your bit is truly 0.25" or maybe .02" undersize! You can test this by simply measuring the bit, or making the tool diameter .23" and regenerating the g-code.

The parts fit very well. Then I made a new rosette, this time in four pieces cut from scrap ---- I didn't have any larger pieces to do it as a single part. I tested this against the pocket where the plywood inlay fit so well. and found the new pieces were a .Hi , I am new to this and have managed to get the Router working ok. The bit that I am finding a bit tricky is the Toolpath , tool selection and settin Chinese 3018 CNC Software Considering that you can get some machines that run off a USB stick without even having to be connected to a PC (my two 3D rinters for example) and that both those and my small 3018 router can be connected to a PC and run from that it is obvious that since the parallel port has been dicontinued, and was last seen at least ten years ago on PC's .

junction box wall mount

cnc 3018 software setup

junction box vs home run

North America Sainsmart 3018 pro cnc; Help using new Laser for SainSmart Genmitsu CNC Router 3018PRO; G540 / UC100 Controller Build for GenMitsu 3018 routers; G540 / UC100 Controller Build for GenMitsu 3018 routers; Newbie-Sainsmart 3018 Pro using Grbl I have just acquired a little 2nd hand CNC 3018 Pro CNC/Engraving machine. Got it home, installed driver plus UGS Universal Gcode Sender and machine seems to work on all axis just fine. So now i need some hopefully freeware to generate gcode for this little machine from STL files I have created with Alibre Design. Recently I cut some Lexan with a 2 flute, straight cutter (1/4") and had better results than the spiral bits. 10,000 RPM (my minimum router speed) and 40-60 IPM produced decent results. I've been told that the single flute bits work even . Hi All, This is my first post and I'm designing a new mini desktop CNC router that I thought I'd share with you guys. My background is about 10 years as a CNC machinist and metal fabricator. I have used equipment such as a HAAS VF2 mill, Daewoo Lynx L200 lathe, Mazak Laser, Flow Waterjet, and Strippet Turret Punch.

I have a new Sainsmart CNC Router 3018-MX3 assembled and Mach3 installed. Control board has a red and green lights on. The spindle motor spins when running a supplied g-code file.

The problem I having I load the gerber file in flatcam done the the gcode when my cnc was Engraving on the pcb I found it was to big in size as I was testing my cnc for problem can any one help me. Similar Threads: Need Help!-New user 3018 CNC problem; Need Help!-New user 3018 CNC problem; Need Help!-CNC 3018 Pro Problem With Z-Probe/Heightmap . Aside from machine ridgidity, I'd check to see if your bit is truly 0.25" or maybe .02" undersize! You can test this by simply measuring the bit, or making the tool diameter .23" and regenerating the g-code. The parts fit very well. Then I made a new rosette, this time in four pieces cut from scrap ---- I didn't have any larger pieces to do it as a single part. I tested this against the pocket where the plywood inlay fit so well. and found the new pieces were a .

Hi , I am new to this and have managed to get the Router working ok. The bit that I am finding a bit tricky is the Toolpath , tool selection and settin Chinese 3018 CNC Software Considering that you can get some machines that run off a USB stick without even having to be connected to a PC (my two 3D rinters for example) and that both those and my small 3018 router can be connected to a PC and run from that it is obvious that since the parallel port has been dicontinued, and was last seen at least ten years ago on PC's . North America Sainsmart 3018 pro cnc; Help using new Laser for SainSmart Genmitsu CNC Router 3018PRO; G540 / UC100 Controller Build for GenMitsu 3018 routers; G540 / UC100 Controller Build for GenMitsu 3018 routers; Newbie-Sainsmart 3018 Pro using Grbl

cnc 3018 pro specifications

I have just acquired a little 2nd hand CNC 3018 Pro CNC/Engraving machine. Got it home, installed driver plus UGS Universal Gcode Sender and machine seems to work on all axis just fine. So now i need some hopefully freeware to generate gcode for this little machine from STL files I have created with Alibre Design.

Recently I cut some Lexan with a 2 flute, straight cutter (1/4") and had better results than the spiral bits. 10,000 RPM (my minimum router speed) and 40-60 IPM produced decent results. I've been told that the single flute bits work even .

Hi All, This is my first post and I'm designing a new mini desktop CNC router that I thought I'd share with you guys. My background is about 10 years as a CNC machinist and metal fabricator. I have used equipment such as a HAAS VF2 mill, Daewoo Lynx L200 lathe, Mazak Laser, Flow Waterjet, and Strippet Turret Punch.

I have a new Sainsmart CNC Router 3018-MX3 assembled and Mach3 installed. Control board has a red and green lights on. The spindle motor spins when running a supplied g-code file.

junction box weatherproof

We do what we say, and we do it on time. See our full plate-to-paint process (best .

3018 cnc router parts|cnc 3018 pro software setup