formability of sheet metal Numbers of theoretical and numerical models have been developed and used to predict the formability of sheet metals. These modelling techniques are primarily developed . Choosing the right surface finish for CNC parts is important to ensure that the part meets the desired functional and aesthetic requirements. Some of the key factors to consider when selecting a CNC machining surface .

0 · thinning in sheet metal forming

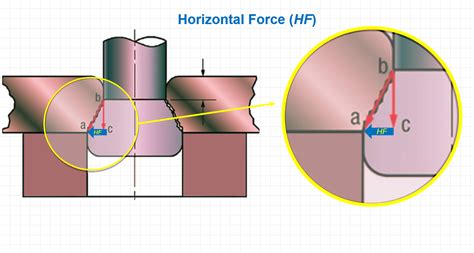

1 · stripping force in sheet metal

2 · stretch forming of sheet metal

3 · sheet metal forming press dies

4 · sheet metal forming by hand

5 · press forming of sheet metal

6 · flanging process in sheet metal

7 · draw forming sheet metal

In the back of a metal junction box will be a "nub" which is threaded for a 10-32 screw. This is for a ground wire. I suppose that what you have found by the two really good answers is that the term "sockets" and "outlets" are not very definitive.

thinning in sheet metal forming

Sheet metal forming operations are so diverse in type, extent, and rate that no single test provides an accurate indication of the formability of a material in all situations. This article presents an . Formability is the ability of a given metal work piece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is .

stripping force in sheet metal

The formability is the capability of sheet metal to undergo plastic deformation to a given shape without defects. The defects have to be .

Formability is the ability of a given metal work piece to undergo plastic deformation without being damaged. The plastic deformation capacity .

Numbers of theoretical and numerical models have been developed and used to predict the formability of sheet metals. These modelling techniques are primarily developed .

Formability is simply the ability of a sheet metal product to be formed into the desired shape reliably and repeatedly using the selected metal grade and stamping system parameters like the forming process, lubrication, die materials, and tool coatings.

Know-how on mechanical behaviour of sheet metal forming operations like deep drawing etc., are very much essential for quality production of articles having wide industrial and domestic applications such as automobile, beverage, aerospace and kitchenware. Forming limit diagram (FLD) is one of the most useful tools to evaluate the formability of sheet metals, which was originally proposed by Keeler [1] for the negative minor strain region, and then extended by Goodwin [2] for the positive minor strain region. The out-of-plane [3], [4] and in-plane [5], [6] formability tests, as two primary experimental methods, have .

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage).. Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping .

stretch forming of sheet metal

The formability of steel sheet is related to various microstructural features of the sheet. The article describes some of the forming characteristics of the more commonly used formable grades. It also lists the typical mechanical properties for common grades of .The formability of sheet metal materials through the deep drawing process is affected by various parameters, such as die chamber pressure, die radius and sheet thickness, all of which directly influence the product’s quality. This paper investigates the formability of the DC01 sheet metal material. DC01 is a carbon steel sheet, which has a .The formability of sheet metal materials through the deep drawing process is affected by various parameters, such as die chamber pressure, die radius and sheet thickness, all of which directly influence the product’s quality. This paper investigates the formability of the DC01 sheet metal material. DC01 is a carbon steel sheet, which has a .5.2 Methods of Evaluating Sheet Metal Formability 179 5.2 Methods of Evaluating Sheet Metal Formability At the end of the nineteenth century, due to the development of the sheet forming technology, sheet metal formability became a research topic. A detailed presen tation of this research can be found in references [5.10 to 5.12].

2.2 Research methodology. In order to study mechanism on the controllable sheet metal formability caused by MRE in the presence of external magnetic field, research strategy shown in Fig. 2 was adopted in this work. At first, stress-strain relationships of MREs containing different contents (φ) of ferromagnetic particles in the presence of external magnetic field with .steel Bubble chart. steel Banana diagram. Steel strength ductility diagram—it’s been called a lot of things over the years. Now called the steel Global Formability Diagram, a new 2021 version is available for download and use. In addition in this article, we define Advanced High-Strength Steels, Ultra-High-Strength Steels and 3rd Generation steels.The process formability of incremental sheet forming (ISF) is better than the conventional forming processes. Stretching, through-thickness-shear, bending-under-tension (BUT), and compressive forces are the proposed deformation mechanisms for improved formability; however, researchers have not corroborated (on consensus) the relative significance of any one among these. .

Formability in sheet metals has dependency on several parameters and processing history of the sheets and also on the microstructure and phases in metals 10,11,12,13,14,15.

A review on modelling techniques for formability prediction of sheet metal forming. Int. J. Lightweight Mater. Manuf., 1 (Issue 3) (September 2018), pp. 115-125. View PDF View article View in Scopus Google Scholar [22] R. Hill. On discontinuous plastic states, with special reference to localized necking in thin sheets.

In this chapter, sheet-metal formability tests, such as the tensile test, the plane-strain test, and the in-plane stretching test are analyzed.The FEM and experimental methods were used in order to demonstrate how two-dimensional in-plane simulation can help interpret and develop such tests, as well as to understand the nature of material behavior and governing mechanics. At the same time, cold recycling, or re-manufacturing, of sheet metals is an emerging area studied mostly empirically; in its current form, it lacks theoretical foundation. In order to address the challenge of residual formability for sheet-metal products, a reformability index is introduced in this study. The prediction of the sheet metal forming limits assumes primary importance, even if the material formability cannot be easily quantified since it depends on many interacting factors related to both the sheet metal under deformation and the applied process parameters [26]. The first attempt to predict the forming limits was the phenomenological . The intrinsic formability of sheet metal is often restricted by the appearance of the plastic flow localization during straining. The sheet metal will fail when the critical limit strain approaches, which is always characterized by the forming limit curve (FLC) plotted in the forming limit diagram (FLD).

Namely, the formability of sheet metal under biaxial stretching is analyzed based on a model of surface roughening caused by a certain distribution of the r-value in sheet metals [14]. 2.1. Equations of plasticity under plane stress.The formability of aluminium sheet at room temperature is lower than for a typical deep drawing steel grade (about two thirds of mild steel). . In sheet metal applications, friction can cause thickness variations within the formed part; excessive thinning can result in localized failure (splits). Moreover, the strain path during sheet metal .

The formability of sheet metal materials through the deep drawing process is affected by various parameters, such as die chamber pressure, die radius and sheet thickness, all of which directly influence the product’s quality. This paper investigates the formability of the DC01 sheet metal material. DC01 is a carbon steel sheet, which has a .The formability of the sheet metal under hot stamping conditions was evaluated by Zhutao Shao et al. [5] using Continuum Damage Mechanics (CDM)-based materials model. The 2D CDM based materials model comprises a set of equations describing the viscoplastic behaviour of material which captures the feature of FLCs. The cruciform specimens as .Testing and modelling of material behaviour and formability in sheet metal forming. Dorel Banabic. CIRP Annals. See full PDF download Download PDF. Related papers. Characterisation and modelling of the plastic material behaviour and its application in sheet . Cold Rolled Steel Sheets Offer a Variety of Outstanding Properties, Including Easy formability and a Smooth, Clean Surface, and is Easy to Weld. : Industrial & Scientific . Our steel sheet metal plates come with a 1/8-Inch tolerance, ensuring enhanced precision for all your project needs. Size: 12” x 24” Thickness: 18 Gauge Metal Type .

large metal house letters

This paper presents a new combined experimental and theoretical methodology for determining the formability limits by wrinkling in sheet metal forming. The methodology is based on the utilization of rectangular test specimens clamped along its narrower sides and compressed lengthwise and is aimed at replicating the physics behind the occurrence of wrinkling in .

The formability of sheet metal is defined as the adaptability of sheet metal to the stamping process, that is, the ability of sheet metal to produce plastic deformation without failure in a specified processing process [1]. The most visualized way to evaluate the formability of sheet metal is the forming limit diagram (FLD).Formability, in the conventional sheet metal–forming process, is the ability of the metal to deform without failure. In ISF, however, the plastic zone is restricted to the small area of contact between the tool and the workpiece, and formability is quantified using the maximum forming or draw angle; sometimes, the depth of forming has also .

Sheet metal formability refers to a material's ability to undergo shaping without failures like necking or tearing. Three main factors influence formability: 1) the metal's properties, 2) friction levels during forming, and 3) the equipment used. Common tests to evaluate formability include cupping, tension, bulge, and forming limit diagrams. .

sheet metal forming press dies

sheet metal forming by hand

press forming of sheet metal

What you’ll find at any hardware store will be pre-rolled dimensional metal studs. They are usually 25 gauge aluminum rated at 33Ksi (kilopounds per square inch) and more commonly known .

formability of sheet metal|stretch forming of sheet metal