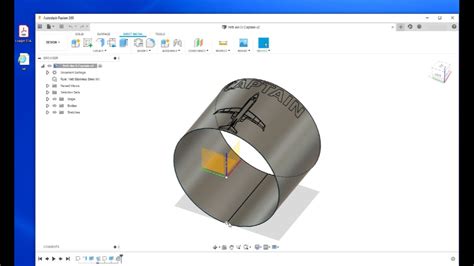

creating sheet metal parts in fusion 360 In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu. Hydraulic pistons smoothly open the waterproof lockable lid, revealing 380L (100Gal) of interior storage on an elevated floor. Perfect for tucking away bulky cushions, garden accessories or sporting equipment.

0 · fusion 360 unfold sheet metal

1 · fusion 360 sheet metal tutorial

2 · fusion 360 sheet metal thickness

3 · fusion 360 sheet metal hem

4 · fusion 360 sheet metal drawing

5 · fusion 360 sheet metal basics

6 · fusion 360 create flat pattern

7 · autodesk fusion 360 sheet metal

QILIPSU Waterproof Junction Box, IP67 Outdoor ABS Plastic Electrical Enclosure with Mounting Plate, Wall Brackets, Weatherproof Hinged Grey Cover for Projects (11.2"x7.7"x5.1")

Thanks to SendCutSend.com for sponsoring this free course!Demo Files: https://bit.ly/F360SheetMetalFusion 360 Sheet Metal tools can be used to design and man.In Fusion, a sheet metal part starts out as a flat piece of metal with a consistent thickness. A flange feature consists of a face and bend connected to an existing face along an edge. In the .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, . In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu.

Create a sheet metal component using Fusion.

By the end of this video, you’ll be able to create a basic sheet metal part in Fusion 360’s sheet metal workspace. You'll learn how to create a base flange, flanges, and how to.Learn how to create and import sheet metal parts in Autodesk Fusion 360. Learn about documenting sheet metal parts. Learn about preparing the nesting layout without and with the .Learn how to create a sheet metal drawing with a bend table and take the part into CAM to be manufactured. Learn some cool tricks with sheet metal, such as creating mitered flanges, .

To make this design, we will cover creating a base flange, adding bends, folding and unfolding the design virtually, adding holes and other features, and creating bending patterns that can be shared with manufacturers to get .

Are you looking to create sheet metal designs with precision and ease? Look no further than Autodesk Fusion 360. This versatile software allows you to design, simulate, and modify sheet metal parts with incredible accuracy. Thanks to SendCutSend.com for sponsoring this free course!Demo Files: https://bit.ly/F360SheetMetalFusion 360 Sheet Metal tools can be used to design and man.In Fusion, a sheet metal part starts out as a flat piece of metal with a consistent thickness. A flange feature consists of a face and bend connected to an existing face along an edge. In the Design workspace, switch to the Sheet Metal toolbar.The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, and practice the principles of manufacturing and begin applying your new skills to real-world projects.

In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu.Create a sheet metal component using Fusion. By the end of this video, you’ll be able to create a basic sheet metal part in Fusion 360’s sheet metal workspace. You'll learn how to create a base flange, flanges, and how to.Learn how to create and import sheet metal parts in Autodesk Fusion 360. Learn about documenting sheet metal parts. Learn about preparing the nesting layout without and with the manufacturing extension.

Learn how to create a sheet metal drawing with a bend table and take the part into CAM to be manufactured. Learn some cool tricks with sheet metal, such as creating mitered flanges, fixing non-orthographic punches, and mirroring sheet metal parts.

fusion 360 unfold sheet metal

fusion 360 sheet metal tutorial

To make this design, we will cover creating a base flange, adding bends, folding and unfolding the design virtually, adding holes and other features, and creating bending patterns that can be shared with manufacturers to get your sheet metal parts made.

Are you looking to create sheet metal designs with precision and ease? Look no further than Autodesk Fusion 360. This versatile software allows you to design, simulate, and modify sheet metal parts with incredible accuracy.

Thanks to SendCutSend.com for sponsoring this free course!Demo Files: https://bit.ly/F360SheetMetalFusion 360 Sheet Metal tools can be used to design and man.

In Fusion, a sheet metal part starts out as a flat piece of metal with a consistent thickness. A flange feature consists of a face and bend connected to an existing face along an edge. In the Design workspace, switch to the Sheet Metal toolbar.

The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, and practice the principles of manufacturing and begin applying your new skills to real-world projects.In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu.Create a sheet metal component using Fusion. By the end of this video, you’ll be able to create a basic sheet metal part in Fusion 360’s sheet metal workspace. You'll learn how to create a base flange, flanges, and how to.

Learn how to create and import sheet metal parts in Autodesk Fusion 360. Learn about documenting sheet metal parts. Learn about preparing the nesting layout without and with the manufacturing extension.Learn how to create a sheet metal drawing with a bend table and take the part into CAM to be manufactured. Learn some cool tricks with sheet metal, such as creating mitered flanges, fixing non-orthographic punches, and mirroring sheet metal parts.

To make this design, we will cover creating a base flange, adding bends, folding and unfolding the design virtually, adding holes and other features, and creating bending patterns that can be shared with manufacturers to get your sheet metal parts made.

fusion 360 sheet metal thickness

fusion 360 sheet metal hem

Get the best deals on Waterloo Collectible Tool Boxes & Chests when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

creating sheet metal parts in fusion 360|fusion 360 sheet metal basics