3d printed sheet metal dies Support these projects on patreon: / stuffmadehere Check out the subreddit: https://tinyurl.com/smhere In this video I show more techniques for 3D printed sheet metal press forming tools. I. Need a custom tailored design for your dumpster enclosure? Since we are a one stop shop, we can tailor you enclosure to your exact specifications! We have some preexisting design options or if you have a design in mind, simply let us know and we will get the job done! Gate panels are Kynar Painted Metal available in 8 key colors.

0 · 3d printing sheet metal

1 · 3d printed sheet metal tooling

2 · 3d printed cast dies

3 · 3d printable sheet metal forming

We’ll work within the confines of your existing space to build the perfect trash enclosure for your needs. Whether you have plans or not, we’ll design a custom structure that fits your needs and specifications. Our modular kits are packaged and shipped to your location, with easy assembly by any local installation team.

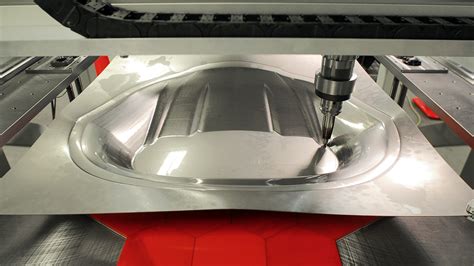

Learn how to use 3D printed tooling for sheet metal forming and dimple dies. Plus, learn which materials to use and get tips and tricks for creating your own. Support these projects on patreon: / stuffmadehere Check out the subreddit: https://tinyurl.com/smhere In this video I show more techniques for 3D printed sheet metal press forming tools. I. Custom Tooling and Fixturing: Creating tools for sheet metal forming, such as dies for stamping or bending, is expensive and time-consuming. With 3D printing, you can precisely . In today's episode, I'm seeing whether 3D Printed Press Dies can help make a custom aluminum panel for my Datsun 280z.

3d printing sheet metal

3d printed sheet metal tooling

Below we outline the process of forming sheet metal parts with 3D printed plastic dies . The report highlights how to leverage in-house additive manufacturing to reduce the cost of toolingThe collaboration between Emiliano Corrieri from Accademia Della Piegatura and Crea3D has resulted in a V-bending die entirely 3D printed, which takes its cue from a version already on the market but made in steel using traditional .

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-scale.

Learn how to use 3D printed tooling for sheet metal forming and dimple dies. Plus, learn which materials to use and get tips and tricks for creating your own.

Support these projects on patreon: / stuffmadehere Check out the subreddit: https://tinyurl.com/smhere In this video I show more techniques for 3D printed sheet metal press forming tools. I. Custom Tooling and Fixturing: Creating tools for sheet metal forming, such as dies for stamping or bending, is expensive and time-consuming. With 3D printing, you can precisely produce these parts to your specifications, cutting costs and wait periods.In today's episode, I'm seeing whether 3D Printed Press Dies can help make a custom aluminum panel for my Datsun 280z.

Below we outline the process of forming sheet metal parts with 3D printed plastic dies . The report highlights how to leverage in-house additive manufacturing to reduce the cost of tooling

The collaboration between Emiliano Corrieri from Accademia Della Piegatura and Crea3D has resulted in a V-bending die entirely 3D printed, which takes its cue from a version already on the market but made in steel using traditional techniques. Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts at large quantities. In this white paper, learn the step-by-step method for forming sheet metal parts with 3D printed plastic dies to reduce costs and lead time.Figur’s patent-pending Digital Sheet Forming (DSF) technology eliminates the need for a traditional stamping press or custom tools, molds, and dies – delivering sheet metal forming that is accessible, flexible, and cost-effective, even at low volumes. In part 2 of the 3D Printed Press Die Series, I'm pressing a much larger sheet metal panel and testing the limits of my 3D Printer.

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-scale.Learn how to use 3D printed tooling for sheet metal forming and dimple dies. Plus, learn which materials to use and get tips and tricks for creating your own. Support these projects on patreon: / stuffmadehere Check out the subreddit: https://tinyurl.com/smhere In this video I show more techniques for 3D printed sheet metal press forming tools. I.

3d printed cast dies

Custom Tooling and Fixturing: Creating tools for sheet metal forming, such as dies for stamping or bending, is expensive and time-consuming. With 3D printing, you can precisely produce these parts to your specifications, cutting costs and wait periods.

In today's episode, I'm seeing whether 3D Printed Press Dies can help make a custom aluminum panel for my Datsun 280z.Below we outline the process of forming sheet metal parts with 3D printed plastic dies . The report highlights how to leverage in-house additive manufacturing to reduce the cost of tooling

The collaboration between Emiliano Corrieri from Accademia Della Piegatura and Crea3D has resulted in a V-bending die entirely 3D printed, which takes its cue from a version already on the market but made in steel using traditional techniques.

Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts at large quantities. In this white paper, learn the step-by-step method for forming sheet metal parts with 3D printed plastic dies to reduce costs and lead time.Figur’s patent-pending Digital Sheet Forming (DSF) technology eliminates the need for a traditional stamping press or custom tools, molds, and dies – delivering sheet metal forming that is accessible, flexible, and cost-effective, even at low volumes.

Fabricating steel sheets can present challenges, such as controlling the thermal expansion and contraction during welding, leading to warping or distortion. Also, steel is susceptible to rust and corrosion without proper treatment and coating. Hence, the fabrication process requires additional surface finishing steps.

3d printed sheet metal dies|3d printing sheet metal