electrical enclosures nema 4 vs nema 4x prolinkdirectory Acceptance of Terms By using the Pro Link Directory Site in any way you are . Sheet metal weight and gauge chart. Stainless steel, copper, zinc, aluminum, steel and galvanized steel.

0 · what is nema 4x rating

1 · nema type 4x meaning

2 · nema enclosure sizes chart

3 · nema 4x stainless steel enclosure

4 · nema 4x specifications

5 · nema 4x hinged enclosure

6 · nema 4 weatherproof enclosure

7 · nema 4 enclosure definition

To make a metal box, first decide on the type of metal, and the size of the box you want to create. I recommend using 20 gauge sheet metal for strength and durability. Copper or brass sheet metal are nice choices as they are inexpensive and they antique nicely.

The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant materials, such as stainless steel and aluminum, can qualify for the NEMA .A SEO friendly free link directory where you can find best sites selected by hand and .Link/Article cancellations by ProLinkDirectory.com .

4ft by 8ft sheet metal

Acceptance of Terms By using the Pro Link Directory Site in any way you are .ProLinkDirectory offers you the ability to submit your articles to a relevant .

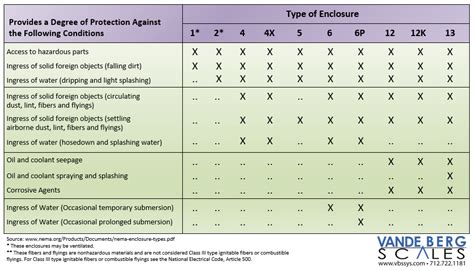

NEMA 4 enclosures give protection from solid and water ingress that can occur from windblown dust, rain, splashing or hose directed water. It can also give protection from ice formation that can possibly occur on the outside surface of . Understanding the key differences between NEMA 4 and NEMA 4X enclosures is critical to ensure optimal protection for your electrical components. While both offer substantial protection, the additional corrosion resistance of .The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant .

NEMA 4X enclosures share many similarities with NEMA 4 enclosures but are specifically designed to offer superior corrosion resistance. They provide the same level of protection against water, dust, and . Evaluating the construction design for the NEMA 4 electrical enclosure, it is quite clear that powerful protection against most environmental conditions. Meanwhile, it is effective for both indoor and outdoor usage.

I have a choice of two NEMA 4X boxes. One is specifically rated NEMA 4X Class 1 Division while the other is just NEMA 4x. My system is going to be used in a Class 1 Division II . The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant materials, such as stainless steel and aluminum, can qualify for .NEMA 4 enclosures give protection from solid and water ingress that can occur from windblown dust, rain, splashing or hose directed water. It can also give protection from ice formation that can possibly occur on the outside surface of the cabinet. Understanding the key differences between NEMA 4 and NEMA 4X enclosures is critical to ensure optimal protection for your electrical components. While both offer substantial protection, the additional corrosion resistance of NEMA 4X enclosures can be .

The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant materials, such as stainless steel and aluminum, can qualify for the NEMA 4X rating. NEMA 4X enclosures share many similarities with NEMA 4 enclosures but are specifically designed to offer superior corrosion resistance. They provide the same level of protection against water, dust, and environmental hazards as NEMA 4 enclosures but excel in harsher environments.

Evaluating the construction design for the NEMA 4 electrical enclosure, it is quite clear that powerful protection against most environmental conditions. Meanwhile, it is effective for both indoor and outdoor usage.

I have a choice of two NEMA 4X boxes. One is specifically rated NEMA 4X Class 1 Division while the other is just NEMA 4x. My system is going to be used in a Class 1 Division II environment and all the electrical components are Class 1 Division 2.NEMA 4 and NEMA 4X enclosures share similarities in terms of their primary purpose for outdoor use and protection against environmental elements. However, there is a key difference between the two: NEMA 4: NEMA 4 enclosures are designed to provide protection against the ingress of solid foreign objects (like dust) and water. NEMA 4. Watertight and for outdoor use. Type 4 provides a degree of protection against rain, sleet, wind-blown dust, splashing/hose-directed water, and damage from ice forming on the exterior of the enclosure. NEMA 4X. Type 4X provides the same protection as type 4 with the addition of corrosion protection. NEMA 5. Dust-tight and for indoor use.

In this article, we’ll break down what enclosure buyers can expect from NEMA 4 enclosures and NEMA 4X enclosures. We’ll also give a quick overview of how corrosion works, and why certain types of devices may need NEMA 4X enclosures for corrosion protection. The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant materials, such as stainless steel and aluminum, can qualify for .NEMA 4 enclosures give protection from solid and water ingress that can occur from windblown dust, rain, splashing or hose directed water. It can also give protection from ice formation that can possibly occur on the outside surface of the cabinet.

Understanding the key differences between NEMA 4 and NEMA 4X enclosures is critical to ensure optimal protection for your electrical components. While both offer substantial protection, the additional corrosion resistance of NEMA 4X enclosures can be .The difference is that the NEMA 4X must provide additional protection against corrosion beyond that provided by the NEMA 4. As a result, only enclosures fabricated from corrosion-resistant materials, such as stainless steel and aluminum, can qualify for the NEMA 4X rating. NEMA 4X enclosures share many similarities with NEMA 4 enclosures but are specifically designed to offer superior corrosion resistance. They provide the same level of protection against water, dust, and environmental hazards as NEMA 4 enclosures but excel in harsher environments.

Evaluating the construction design for the NEMA 4 electrical enclosure, it is quite clear that powerful protection against most environmental conditions. Meanwhile, it is effective for both indoor and outdoor usage.

I have a choice of two NEMA 4X boxes. One is specifically rated NEMA 4X Class 1 Division while the other is just NEMA 4x. My system is going to be used in a Class 1 Division II environment and all the electrical components are Class 1 Division 2.NEMA 4 and NEMA 4X enclosures share similarities in terms of their primary purpose for outdoor use and protection against environmental elements. However, there is a key difference between the two: NEMA 4: NEMA 4 enclosures are designed to provide protection against the ingress of solid foreign objects (like dust) and water.

NEMA 4. Watertight and for outdoor use. Type 4 provides a degree of protection against rain, sleet, wind-blown dust, splashing/hose-directed water, and damage from ice forming on the exterior of the enclosure. NEMA 4X. Type 4X provides the same protection as type 4 with the addition of corrosion protection. NEMA 5. Dust-tight and for indoor use.

what is nema 4x rating

The perfect size for automotive sheet metal is between 18 to 20 gauge. 20 gauge is the most used gauge sheet metal for automotive functions. The abundant metal will be 0.0478 to 0.0359 inches and still need to be cautious about the bumper and metal finish.

electrical enclosures nema 4 vs nema 4x prolinkdirectory|nema 4x hinged enclosure