astm sheet metal thickness tolerance Since 24 Ga has an ASTM range of .0236 to .0316, the midpoint is .0276. And since ALL steel weighs approximately 41.88 lbs per cubic foot, the nominal weight of 24 Ga 60″ wide material . Find a variety of vintage and antique storage cabinets on 1stDibs, including unique Art Deco storage cabinets, chinoiserie cabinets and more. Shop our vintage 1950s metal kitchen cabinets selection from top sellers and makers around the world. Global shipping available.

0 · steel thickness tolerance chart

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · ASTM sheet metal gauge chart

Explore a wide range of our Antique Soap Box selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy returns!

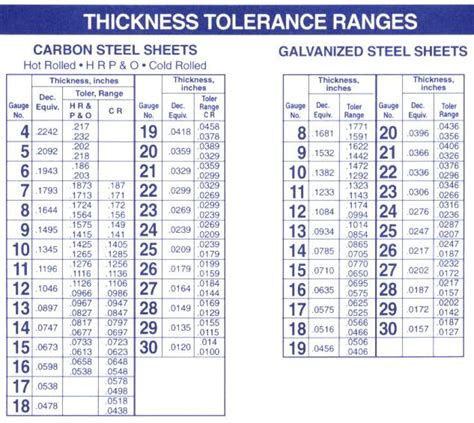

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, .Various ASTM Specs for Steel Sheets A366 Cold Rolled Commercial Quality A569 Hot Rolled Commercial Quality A570 Hot Rolled Structural Quality A526 Zinc Coated (Galvanized) Steel .Since 24 Ga has an ASTM range of .0236 to .0316, the midpoint is .0276. And since ALL steel weighs approximately 41.88 lbs per cubic foot, the nominal weight of 24 Ga 60″ wide material .

1.8 Metallic-coated steel sheet covered by this specification is produced to thickness requirements expressed to 0.001 in. [0.01 mm] for both coils and cut lengths. The thickness is .

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect .

(ASTM 924/97A) Out-of-square is the greatest deviation of an end edge from a straight line at right angles to a side and touching one corner. It is also out-of-square deviation is one half of .These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); .

Thickness, width and length tolerances for A36 plates are in accordance with ASTM A6. ASTM A6 Half-Standard Flatness tolerances are available for plate thicknesses of 3/8 inches to 3.0 . The following table from ASTM A568/A568M – 13a provides the tolerances for hot rolled sheet steel. The tolerances include variation along the coil length and across the coil width. The variation attributable to the profile .

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.

Various ASTM Specs for Steel Sheets A366 Cold Rolled Commercial Quality A569 Hot Rolled Commercial Quality A570 Hot Rolled Structural Quality A526 Zinc Coated (Galvanized) Steel A526/A527 Galvanneal A591 Electrolytically Zinc PlatedSince 24 Ga has an ASTM range of .0236 to .0316, the midpoint is .0276. And since ALL steel weighs approximately 41.88 lbs per cubic foot, the nominal weight of 24 Ga 60″ wide material is .0276 * 41.88 * 5’.or 5.78 lbs. per foot.1.8 Metallic-coated steel sheet covered by this specification is produced to thickness requirements expressed to 0.001 in. [0.01 mm] for both coils and cut lengths. The thickness is the total of the vase steel and the coating. 1.9 The values stated in inch-pound units or SI units are to be regarded separately as standard. Within the text, the .

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.(ASTM 924/97A) Out-of-square is the greatest deviation of an end edge from a straight line at right angles to a side and touching one corner. It is also out-of-square deviation is one half of that difference. The tolerance for all thicknesses and all sizes is 1/16 inch (.0625) per 6 inches of width or fraction thereof. STANDARD ASTM MILL TOLERANES

These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); and ASTMA653/A653M-94, Standard Specification for Sheet Steel, Zinc-Coat (Galvanized) or Zinc-Iron Alloy Coated (Galvanized) by the Hot-Dip Process.Thickness, width and length tolerances for A36 plates are in accordance with ASTM A6. ASTM A6 Half-Standard Flatness tolerances are available for plate thicknesses of 3/8 inches to 3.0 inches. Inquire for specific mill flatness capabilities. The following table from ASTM A568/A568M – 13a provides the tolerances for hot rolled sheet steel. The tolerances include variation along the coil length and across the coil width. The variation attributable to the profile can be in the order of 1 – 5% of the average thickness depending on a variety of factors.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.

Various ASTM Specs for Steel Sheets A366 Cold Rolled Commercial Quality A569 Hot Rolled Commercial Quality A570 Hot Rolled Structural Quality A526 Zinc Coated (Galvanized) Steel A526/A527 Galvanneal A591 Electrolytically Zinc PlatedSince 24 Ga has an ASTM range of .0236 to .0316, the midpoint is .0276. And since ALL steel weighs approximately 41.88 lbs per cubic foot, the nominal weight of 24 Ga 60″ wide material is .0276 * 41.88 * 5’.or 5.78 lbs. per foot.1.8 Metallic-coated steel sheet covered by this specification is produced to thickness requirements expressed to 0.001 in. [0.01 mm] for both coils and cut lengths. The thickness is the total of the vase steel and the coating. 1.9 The values stated in inch-pound units or SI units are to be regarded separately as standard. Within the text, the .Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.(ASTM 924/97A) Out-of-square is the greatest deviation of an end edge from a straight line at right angles to a side and touching one corner. It is also out-of-square deviation is one half of that difference. The tolerance for all thicknesses and all sizes is 1/16 inch (.0625) per 6 inches of width or fraction thereof. STANDARD ASTM MILL TOLERANES

These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); and ASTMA653/A653M-94, Standard Specification for Sheet Steel, Zinc-Coat (Galvanized) or Zinc-Iron Alloy Coated (Galvanized) by the Hot-Dip Process.

Thickness, width and length tolerances for A36 plates are in accordance with ASTM A6. ASTM A6 Half-Standard Flatness tolerances are available for plate thicknesses of 3/8 inches to 3.0 inches. Inquire for specific mill flatness capabilities.

high precision milling part manufacturer

Find many varieties of an authentic brass plant stands antique available at 1stDibs. Frequently made of metal, brass and wood, every brass plant stands antique was constructed with great care.

astm sheet metal thickness tolerance|stainless steel sheet tolerance chart