cnc machining parameter Setting CNC machine parameters correctly is crucial for ensuring precision, efficiency, and the overall success of the machining process. The following eight steps outline the process from initialization to execution, . Neither under sells or over presents in shape, size, color, or design. Adding it as the final touch to your setup before entertaining guests will give you that "Ahh" moment when everything comes together perfectly. Made from thick gauge steel, indoor/outdoor use, modular. Rust resistant, commercial grade.

0 · data entry cnc parameter

1 · cnc parameters explained

2 · cnc parameters examples

3 · cnc parameter settings

4 · cnc machining parameters list

5 · cnc machining parameters explained

6 · best cnc parameters

7 · 7 cnc parameters

Whether you're looking for show-stopping style or a classic silhouette, explore our collection of dresses from Versace for the perfect outfit. This designer's dresses are made from the finest of fabrics, including linen and silk, so you'll be feeling as good as you look.

Setting CNC machine parameters correctly is crucial for ensuring precision, efficiency, and the overall success of the machining process. The following eight steps outline the process from initialization to execution, . Hello Steve, It would help if you were to identify the Type of machine, ie., Lathe or Mill. If a lathe, and as a Lathe Control doesn't have a dedicated G73 High Speed Peck Cycle (G73 is a Pattern Repeat, Multi-repetitve Cycle), parameter bit 5101.2 needs to be set to either 0, or 1 to specify the behavior of the G83 Cycle. I'm looking for a parameter controls rapid moves so that during a diagonal direction move, it will move in a straight line to the new location. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical . CNC Machining . fanuc option parameters. Thread starter turner13; Start date Apr 10, 2008; Replies 6 Views 29,886 T. turner13 Aluminum. Joined May 31, 2007 . but does anyone know how to switch the option parameter write enable on a DOOSAN 21i FANUC control.

Optimization of CNC Milling Parameters – Machining Parameters Selection. Note: The selection principle of machining parameters for milling operation is to give full play to the working efficiency and cutting performance of the machine tool on the premise of ensuring the machining quality. Under the condition that the rigidity of the process . If your machine is a 3 or 4 axis machining centre, then its quite likely that only System Variable #5083 will have a value registered. System Variables #5081 to #5088 are System Variables for Tool Length Offsets.

and my these machine optional parameter is visible and i can edit and change any word in optional parameter 9900 to 9998 . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way . Figured I'd ask a few questions of my own to help myself better understand what some parameters do and see if I can make our machine more accurate in the process. The machine in question is a CR Onsrud 5 axis gantry style router running Fanuc 31i-B5. Stationary table, gantry moves in X, ball screw for Y, entire mast moves for Z, and the head . Bah, As far as I'm concerned the machine comes with a control, I bought the machine and the control. The parameters are there to control specific functions of the machine and I have every right to edit or change them to suit my needs as required.Section 1 – Main parameters: Cutting speed, feedrate, Feed per Tooth, . Machining Power (All Applications): Based on raw material and MRR. Metal Removal Rate (All Applications): Based on cutting data and tool geometry. Cut Time (All Applications): Given for a nominal distance (100 mm or 4″ for turning, 10 mm or 3/8″ for grooving, etc.)

We have two new (to us) Doosan Lynx 220L lathes with Fanuc Oi controllers. When I'm doing setups and I call up a tool through MDI to take a skim cut, check for clearance, impress my girlfriend, whatever, as soon as I hit RESET the tool geometry goes away and I'm back to machine absolute.

data entry cnc parameter

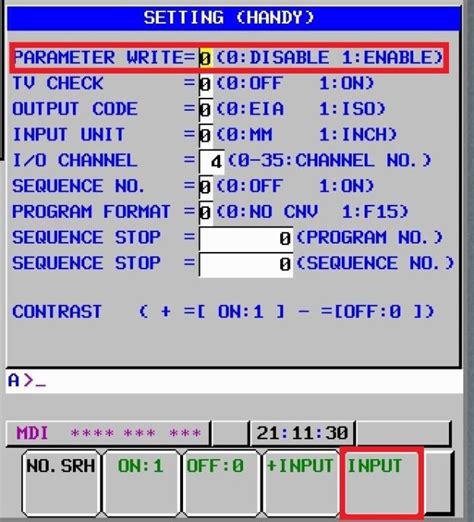

Go to the offset setting pages under settings there is a parameter write enable you need to be in MDI press 1 input to enable. the machine will alarm, now you can change to 9000 programs just make sure you go back in and turn the parameter write disable back on so you don't change something else on accident or have some one else changing things. CNC Machining ABOUT PRACTICAL MACHINIST With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. CNC machine parameters are the various settings that allow the machine to perform specific tasks accurately and efficiently. 1. Axis Parameters. The axis parameters are the settings that control the movement of the CNC machine. CNC machines typically have three to five axes, and each axis has its own parameters. These parameters control the . This doesn't work at the shop I'm currently at. Is there a parameter that can be changed to enable this? Fanuc Oi series controller. I've already changed #5213 and # 5214 to limit wear offset max and incremental input of wear offsets. Are there any other parameters that you typically like to check and change when a new machine rolls into the shop?

CNC Machining . Find parameter 5006 in Fanuc OM. Thread starter Monsieurmark; Start date Dec 25, 2017; Replies 0 Views 1,208 . “Bryan, there is a bit parameter in the settings that will make it where you don't jump suddenly in Z when you change turn on/off the tool compensation or apply a new tool number. I think it might be parameter 5006 .

went into the parameters and checked and everything looks fine. i try homing the machine with the menu and i get the same message although i can home it with job and type cs it works. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for .

If the machine is operating effectively, leave them as set in the actual machine's control. If you don't already have communication successfully established between machine and the outside world, you may be looking at parameter #553 in unison with other parameters, in making that happen, but only if the I/O setting parameter is set to 1.

cnc parameters explained

cnc parameters examples

cnc parameter settings

CNC Machining . Fadal parameters and tuning. Thread starter toadjammer; Start date Jul 10, 2020; Replies 8 Views 2,707 . Ultimately that control doesn't have much that's tweakable in regards to the parameters of the machine motion as far as I'm aware. If you're running in G8 (which you likely are/should be) then as far as I know the control . Ignore this and navigate to the parameter you want to change. Most of the parameters are in 8 Bit format with bit Zero right most and counts towards the left to bit seven. Parameter 0552 is in Decimal Format and 10 will be registered for 4800 Baud Rate, 11 for 9600 Baud. Once you have finished setting parameters, the PWE has to be set back to "0".

today in this article I will explain how to set the machining parameters of your CNC machine in a simple and safe way, even if you have little or no experience. It is indeed essential to machine with the right parameters to avoid burning the wood and making the surface rough, as well as risking breaking the router bit and even hurting yourself!

I need to either find the parameter value so I can put in H#5200 (example) so it will use whichever tool is in - or i will need to right a macro and use 3 sub programs for the different tools - which then I will probably need to find the variable for the 'T' value. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique .

I'm trying to set the silly thing up in the parameters. The manual says G900 is the distance from the table to the probe, G901 and G902 being the X-Y positions, G903 changes whether the offset is from the spindle or the bottom of the machine (mine is a high column, 300mm), G904 being breakage detection tolerance, G905 being overrun distance,and . i have compiled a list of fanuc option parameters in an excel spreadsheet. free to all interested. it also lists the 100% operational cad/cam packages i have available. [email protected] I have a Mori MV35/40 with Yasnac MX1 controller and 20 position tool changer and am looking for the parameter settings. I am mainly looking for the option settings and settings pertaining to the 20 position tool changer located in parameters 6030-6049 & 7000-7095. Ive had some discussion and.

Machining is one of the eight basic manufacturing processes. This textbook covers the fundamentals and engineering analysis of both conventional and advanced/non-traditional material removal . Control Parameters Ok, thank you Bill for your posts in this thread. WRT the parameters you listed in your first post, I have the following for #26: . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical . The 2 parameters combine to 3 different combinations- LF only, CR+LF, and LF+CR+CR. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers .

dengerus metal in the old house such as

definition of enclosure electrical divider

Made of exquisite foil covered pleated polyester, it is designed to stretch in the direction of the folds, making it incredibly versatile and perfect for creating iconic statement pieces. Sleek, elegant and absolutely captivating, our Titanium Pleated Polyester Fabric feels luxurious to the touch and exudes pure sophistication.

cnc machining parameter|cnc parameter settings