cnc machine coolant concentration To ensure optimal performance, you must monitor, maintain, and adjust central and individual CNC .

TRIEB SHEET METAL COMPANY: Commercial Heating Ventilating-Air Conditioning Full Mechanical Contracting Plans and Spec. Design Build Phone: 913-831-1166 Fax: 913-831-4577 Mailing Address: P.O. Box 6797 Kansas City, Kansas 66106 Shipping Address: 1642 South 45th Street Kansas City, Kansas 66106 Contacts: Dan Tumberger

[email protected] .

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Your number one resource for custom metal stamping. We have been one of the leading deep draw metal stamping manufacturers since 1933. Our customers depend on Wedge Products to deliver high-quality products with speedy shipment and competitive pricing.

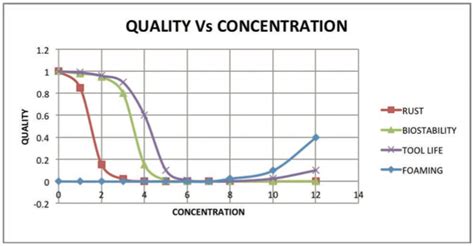

To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best . Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary .

Coolant concentration plays a critical role in CNC machining processes. The primary purpose of using a coolant is to reduce heat and friction generated during the cutting process. The coolant .

CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC . It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal .

To ensure optimal performance, you must monitor, maintain, and adjust central and individual CNC . To check the concentration of coolant you’ll need to use a refractometer. This device uses a special scale, called Brix scale, to show the density of the water sample. Some types of coolant might require you to apply .

machine coolant concentration chart

Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, .

CNC machine coolants play a vital role in achieving optimal efficiency in a CNC shop by reducing heat build-up, lubricating cutting tools, and preventing discoloration and . Find the Right Coolant Concentration. Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of most 3-axis CNC machines provide detailed data on the necessary type of coolant and the coolant’s concentration level.

To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best practices. This chart provides a guideline for coolant concentration levels based on the type of material being machined and the cutting parameters involved.

Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary depending on the specific machining operation.

coolant tank for cnc machine

Coolant concentration plays a critical role in CNC machining processes. The primary purpose of using a coolant is to reduce heat and friction generated during the cutting process. The coolant accomplishes this by lubricating the cutting tool and removing .

CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface. It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal concentration, consider the specific operation at hand.

To ensure optimal performance, you must monitor, maintain, and adjust central and individual CNC machine coolant systems. However, small coolant systems use less efficient components for oil separation and filtration, resulting in constant and variable concentration levels. To check the concentration of coolant you’ll need to use a refractometer. This device uses a special scale, called Brix scale, to show the density of the water sample. Some types of coolant might require you to apply a specific correction factor when measuring the concentration in the refractometer.

Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, ensuring efficient operation and extended tool life. CNC machine coolants play a vital role in achieving optimal efficiency in a CNC shop by reducing heat build-up, lubricating cutting tools, and preventing discoloration and failure in various machining processes such as CNC milling, turning, or drilling.

Find the Right Coolant Concentration. Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of most 3-axis CNC machines provide detailed data on the necessary type of coolant and the coolant’s concentration level.To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best practices. This chart provides a guideline for coolant concentration levels based on the type of material being machined and the cutting parameters involved. Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary depending on the specific machining operation.Coolant concentration plays a critical role in CNC machining processes. The primary purpose of using a coolant is to reduce heat and friction generated during the cutting process. The coolant accomplishes this by lubricating the cutting tool and removing .

coolant system for milling machine

CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface. It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal concentration, consider the specific operation at hand.

To ensure optimal performance, you must monitor, maintain, and adjust central and individual CNC machine coolant systems. However, small coolant systems use less efficient components for oil separation and filtration, resulting in constant and variable concentration levels. To check the concentration of coolant you’ll need to use a refractometer. This device uses a special scale, called Brix scale, to show the density of the water sample. Some types of coolant might require you to apply a specific correction factor when measuring the concentration in the refractometer. Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, ensuring efficient operation and extended tool life.

cnc butt fusion machine suppliers

cnc carving machine diy

Our mission would be to build inventive products to consumers with a superior working experience for wholesale aluminum machining parts, Resin 3d Printing Parts, Turning Machining Aluminum Parts, Cnc Machining Prototyping Parts,Sheet Metal Fabrication. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand .

cnc machine coolant concentration|best coolant for cnc machine