arc welding box section steel Shielded metal arc welding is the process of joining two metal pieces using a flux covered electrode which is melted in an electric arc and becomes a fused part of the pieces being welded. This article will describe the . Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified. Experience lead times as short as 1 day.

0 · welding shielded metal

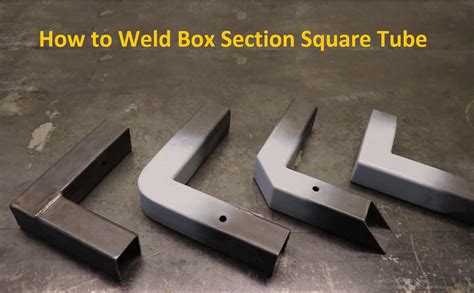

1 · welding box section corners

2 · square tube 90 welding

3 · how to weld box corners

4 · arc welding for 2mm steel

5 · arc welding 3mm steel

eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials.

Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Just about any arc set will weld 2mm, the chances of success more to do with the operator than the machine, you should manage fine after a few practice runs if you have .

Shielded Metal Arc Welding (SMAW) is defined by the American Welding Society (AWS) as an arc welding process with an arc between a covered electrode and the weld pool.

sheet metal surface treatment

Arc / stick welding box section corners, harnessing the heat warp, making it work for you. Shielded metal arc welding is the process of joining two metal pieces using a flux covered electrode which is melted in an electric arc and becomes a fused part of the pieces being welded. This article will describe the .Using arc welding can make it more effective if you know how to do it. Before you finally start to fix the item that is probably pricy, you must practice the arc welding on thin metal more and more. To get the skill, try padding, butt joint, and tee . Built-up box members are fabricated by assembling four steel plates and welding by submerged arc welding (SAW), as shown in Fig. 1. Because SAW has a high heat input, the influence on strength and toughness .

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

welding shielded metal

The welding of Hollow Structural Sections (HSS) does have some unique features. Unlike open sections, where welding is typically possible from both sides of an element, welding of HSS is . Is it possible to just fusion tack the galvanised mesh to the box section using a short pulse of the foot pedal with the TIG torch or would I have to take the coating off first? Would .

Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Just about any arc set will weld 2mm, the chances of success more to do with the operator than the machine, you should manage fine after a few practice runs if you have welding knowledge. Have you considered one of the panel adhesives used by the motor trade or does it have to be welded?

Here's some early attempts at using my cheap little Wolf arc welder to join pieces of steel angle iron which have walls of about 3mm thick. In places the walls seem nearer 4mm. In the first image, I joined two pieces of angle iron to make a bit of box section, to hold a .

Shielded Metal Arc Welding (SMAW) is defined by the American Welding Society (AWS) as an arc welding process with an arc between a covered electrode and the weld pool. If you can't get box section a tight size to fit inside your box you can custom make a box section from 2 pieces of angle iron trimmed to fit & welded along the edges.

Arc / stick welding box section corners, harnessing the heat warp, making it work for you.

Shielded metal arc welding is the process of joining two metal pieces using a flux covered electrode which is melted in an electric arc and becomes a fused part of the pieces being welded. This article will describe the use of flux-coated welding rods and a simple, transformer type cracker box welding machine.Using arc welding can make it more effective if you know how to do it. Before you finally start to fix the item that is probably pricy, you must practice the arc welding on thin metal more and more. To get the skill, try padding, butt joint, and tee joint in a different position on thin metal. Built-up box members are fabricated by assembling four steel plates and welding by submerged arc welding (SAW), as shown in Fig. 1. Because SAW has a high heat input, the influence on strength and toughness at the HAZ is of concern.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. Here's some tips on cutting, welding and finishing steel box corners to a seamless finish.

sheet metal tools aviation

Just about any arc set will weld 2mm, the chances of success more to do with the operator than the machine, you should manage fine after a few practice runs if you have welding knowledge. Have you considered one of the panel adhesives used by the motor trade or does it have to be welded? Here's some early attempts at using my cheap little Wolf arc welder to join pieces of steel angle iron which have walls of about 3mm thick. In places the walls seem nearer 4mm. In the first image, I joined two pieces of angle iron to make a bit of box section, to hold a .Shielded Metal Arc Welding (SMAW) is defined by the American Welding Society (AWS) as an arc welding process with an arc between a covered electrode and the weld pool. If you can't get box section a tight size to fit inside your box you can custom make a box section from 2 pieces of angle iron trimmed to fit & welded along the edges.

Arc / stick welding box section corners, harnessing the heat warp, making it work for you. Shielded metal arc welding is the process of joining two metal pieces using a flux covered electrode which is melted in an electric arc and becomes a fused part of the pieces being welded. This article will describe the use of flux-coated welding rods and a simple, transformer type cracker box welding machine.

welding box section corners

square tube 90 welding

Using arc welding can make it more effective if you know how to do it. Before you finally start to fix the item that is probably pricy, you must practice the arc welding on thin metal more and more. To get the skill, try padding, butt joint, and tee joint in a different position on thin metal. Built-up box members are fabricated by assembling four steel plates and welding by submerged arc welding (SAW), as shown in Fig. 1. Because SAW has a high heat input, the influence on strength and toughness at the HAZ is of concern.

sheet metal tabs

how to weld box corners

Zmetal Precious has a leading CNC machining parts factory in China. We deliver high-quality products with custom solutions at wholesale prices. Trust us for fast delivery, and get a free quote now!

arc welding box section steel|welding shielded metal