different metal brackets In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, . Rubbermaid 14.5-Inch Peel Resistant Metal Twin Track Closet Shelf Bracket in White for Wood/Wire Shelving

0 · types of brackets hardware

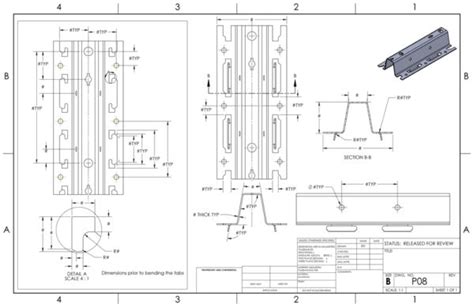

1 · sheet metal bracket design guidelines

2 · rectangular metal bracket

3 · metal bracket with screw holes

4 · home depot metal braces

5 · existing designs for brackets

6 · different types of metal brackets

7 · bendable metal brackets

Shop White Metal Shelving Hardware & Brackets from our Shelving Department at The Home Depot Canada.

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, .

When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.

types of brackets hardware

sheet metal bracket design guidelines

The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting . Bracket variations differ depending on the uses and the things they are meant to support. L-brackets, Box brackets, J-brackets, U-brackets, gusset brackets, and Z-brackets .Metal brackets are highly versatile, strong, and durable, making them ideal for a broad range of applications, including construction, manufacturing, automotive, and aerospace. They can be produced using several methods, such as CNC machining, . In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications.

When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves. Bracket variations differ depending on the uses and the things they are meant to support. L-brackets, Box brackets, J-brackets, U-brackets, gusset brackets, and Z-brackets are a few of the metal bracket configurations. J-brackets are frequently employed in automotive applications and construction.Whether you need a bracket for your industrial, commercial, or private project, custom metal brackets are essential to fit the dimensions of your space safely and securely. Bespoke metal shelving brackets provide support and structural integrity to numerous applications.

Sheet metal brackets are components made from sheet metal through cutting, bending, and forming processes designed to support or attach structures. They come in various shapes and sizes, including flat, angle, U, and Z shapes, and are typically made from steel, aluminum, or brass materials.A mounting bracket is a general term to describe brackets used for different kinds of mounting requirements needed when installing a shade sail. There are several kinds, including internal corner brackets, external corner brackets, diamond pad eyes, and wall plates.Choose from our selection of steel brackets in a wide range of styles and sizes. In stock and ready to ship.

Metal brackets are hardware components made from various metals, including steel, aluminum, and iron. They are designed to provide structural support, enhance stability, and facilitate secure connections in multiple applications.Metal brackets are highly versatile, strong, and durable, making them ideal for a broad range of applications, including construction, manufacturing, automotive, and aerospace. They can be produced using several methods, such as CNC machining, . In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications.

When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves. Bracket variations differ depending on the uses and the things they are meant to support. L-brackets, Box brackets, J-brackets, U-brackets, gusset brackets, and Z-brackets are a few of the metal bracket configurations. J-brackets are frequently employed in automotive applications and construction.Whether you need a bracket for your industrial, commercial, or private project, custom metal brackets are essential to fit the dimensions of your space safely and securely. Bespoke metal shelving brackets provide support and structural integrity to numerous applications.

rectangular metal bracket

Sheet metal brackets are components made from sheet metal through cutting, bending, and forming processes designed to support or attach structures. They come in various shapes and sizes, including flat, angle, U, and Z shapes, and are typically made from steel, aluminum, or brass materials.A mounting bracket is a general term to describe brackets used for different kinds of mounting requirements needed when installing a shade sail. There are several kinds, including internal corner brackets, external corner brackets, diamond pad eyes, and wall plates.Choose from our selection of steel brackets in a wide range of styles and sizes. In stock and ready to ship.

metal bracket with screw holes

home depot metal braces

existing designs for brackets

different types of metal brackets

Black stainless steel appliances with white cabinets, in particular, offer a modern appearance and a sleek finish. On the other hand, pairing your black appliances with blue cabinets or other hues like green adds depth and a classic look to your kitchen.

different metal brackets|sheet metal bracket design guidelines