how to cnc mill parts Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine . For a #8 screw, use a 3/ 32″ drill bit for drilling softwood and a 1/8″ drill bit for drilling hardwood. The closest match you can get to the diameter of a #8 screw without the threads is a 1/8” straight drill bit. This number translates to 0.125” or 3.175 mm.

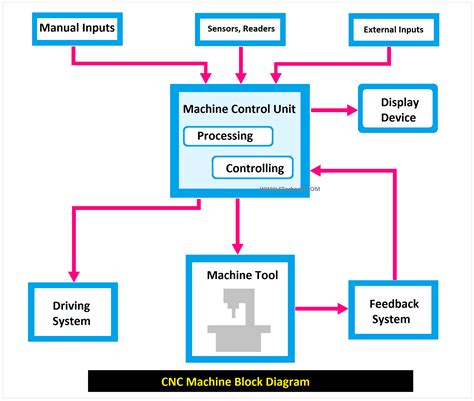

0 · schematic diagram of cnc machine

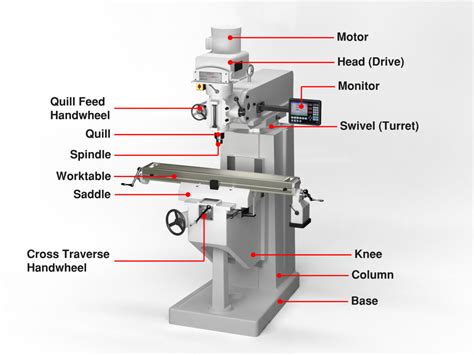

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Rayon is manufactured from wood pulp that is chemically dissolved and undergoes a multi-step process resulting in the soft, lustrous rayon fibres. Polyester on the other hand, is a synthetic material with long, stable fibres that gives it the strength it is best known for.

schematic diagram of cnc machine

Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine . I need to do some machining on very long parts (approximately 9' long) which is much longer than the X travel on my CNC machines. I can run them on an open-sided bed mill so I can hang the parts off side of the . The table is another crucial component of a CNC milling machine, as it determines the size and shape of the parts that can be produced. A larger table will allow the machine to cut larger parts, while a smaller table may be .

These rigid and powerful machines consist of various parts that work in synchronization to perform the desired milling operation. Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work .

At times, some of these parts will have reasonably tight tolerances for parallelism and/or flatness, for example +/- .002 on dimension, or .0008 total parallelism. I'll admit - I am rather inexperienced with CNC milling. I've had to take on the role of programmer due to our previous man leaving, and I really want to try to solve this problem.

If you imagine what a detail should be, we are imagining how to do it.Professionally, efficiently and quickly execute your part.Contact us: https://bnkmachin.Flexibility: Many CNC Milling robots are easy to reprogram for different parts and jobs. They can handle a variety of materials, part sizes, and milling operations - Perfect for high-mix shops. When choosing a CNC Milling robot, consider the types of parts you produce, your shop's needs, and available floor space.CNC milling is a mechanical method that is used to make parts or components that have been specifically developed. . this is beneficial for job shops that utilize turn-mill machines since it allows them to produce parts more cheaply. A single turn-mill machine may execute procedures that previously required three, four, or five machines .

Choosing the right material is crucial for the functionality and durability of your CNC milling parts. Advantages of CNC Milling Parts. Precision: CNC machines offer high accuracy, ensuring parts meet exact specifications. Repeatability: Ideal for producing multiple identical parts. Versatility: Capable of creating complex shapes and intricate .

oday we set up the machine to finish machining the bottom of the part we started in Episode 1!Stay tuned for more CNC related educational videos.Thank you to. CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.

A CNC milling machine is a computer-controlled machine tool used for milling. It is a very versatile machine that can perform many operations. In this . As a CNC machine operator, you have to oversee the CNC machines. Quality parts need specific tools. The drawings are engineering-centered. I advise users to undertake high-skilled .Copper milling. Copper is an incredibly versatile metal, making it an optimal choice for producing CNC machined custom parts.The alloy has several useful properties alongside its versatility—this is why companies working in industries such as electrical, construction, transport and consumer goods use it for many applications. Discover why climb milling is a must for thin-walled parts. Get expert tips and advice for optimizing your CNC milling process at CNCCookbook.com. GW CALCULATOR. GW CALCULATOR; GW EDITOR; . Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great .CNC Milling Machine Parts. There are various components of the general CNC milling machine. Let’s see them one by one. 01. Column. The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine.

Fixturing methods for parts too large for a traditional 6" vise. Let's cover how to use low profile mod vises, super glue fixturing for large parts, brass to. In this CNC milling machine tutorial, we will provide a comprehensive guide on how to use a CNC milling machine. We will cover the basics of CNC milling mach.

milling machine parts diagram

In conclusion, designing parts for CNC milling necessitates engineering expertise and a practical understanding of the manufacturing process. By optimizing the design for CNC milling, parts can be produced more efficiently and accurately, . This post discusses the importance of accuracy and precision in CNC milling and some tips to improve precision and accuracy in CNC milling. [email protected]. 866.262.6233 REQUEST A QUOTE. HOME; . There is a great deal of importance when it comes to accuracy and precision in CNC milling. To produce the highest quality parts and products, all . CNC milling and milling are two very similar processes that can create identical products, but they each have their own strengths and weaknesses depending on the task at hand. For example, in many cases CNC milling can save time and money over traditional milling, while some tasks may be better suited to the craftsmanship of manual milling tools.eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials. Online Ordering. Free Shipping. Quality Guaranteed.

For making gun parts with a CNC machine, beginners should also calibrate the machine, program cutting paths, and maintain the correct feed rates and spindle speeds for different materials. Regularly inspecting and replacing cutting tools is essential .

These cnc machinist tricks will help save you from a lot of scrapped parts and a lot of headaches when it comes to machining thin parts.Aerospace ISOGRID Fre. CNC Machinists – Running production mill turned parts takes a specialized machinist as they must think in both milling and turning (lathe) operations. Check our open positions for job openings for CNC Mill Turning Machinists. Inspection Capabilities – With high rates of production for complicated parts, mill turn production lines require .Mill Automatic Parts Loader CNY ONLY. Not Currently Available In Your Region Automate Your Part Production on Small VMCs The Haas Automatic Parts Loader is a simple and affordable way to automate part production and boost productivity. . Includes CNC Control Cabinet Cooler, Remote Jog Handle-Touch, and Auto Door when ordered with a machine . How To Use A CNC Milling Machine: Step-by-Step Instructions. CNC mills are computer numerical controlled milling machines, which come with 3, 4 or 5 axes to perform milling job simultaneously.. CNC milling machine is a high-precision metal fabricator with a high-speed spindle, high-power servo motor and heavy-duty machine bed structure, which works similar to .

From beginners seeking a better understanding of CNC machine parts to experienced professionals looking for a reliable parts catalog, this guide covers it all. Bookmark this page, download the PDFs, and enhance your CNC machine setup for optimum performance and productivity. . Equipped with 3-4-5 axis CNC milling and CNC turning machines .CNC milling is utilized broadly in assembling bike parts, including cranksets, brake parts, and bike stems. Manufacturers remove the material from a workpiece to make complicated shapes and features. Rotating cutting apparatuses on CNC milling machines definitively eliminates material from the workpiece as per prearranged guidelines.

Some projects call for specific drill bit sizes, but a bit set that includes sizes from 1/16 inch to 1/4 inch will work for many jobs around the home and workshop. You can add .

how to cnc mill parts|cnc mill diagram