diy sheet metal forming 1. Place the sheet metal in the correct position on the positive die and slide the negative on top! It's like a little metal sandwich! 2. Find a long, metal cylinder that will fit between the two . The term storage bin term is commonly used when referring to a shipping container, however, we rarely use it because to us the term ‘bin’ also refers to both plastic bins (typically used for home storage of small items or packing), or larger open roof bins . See more

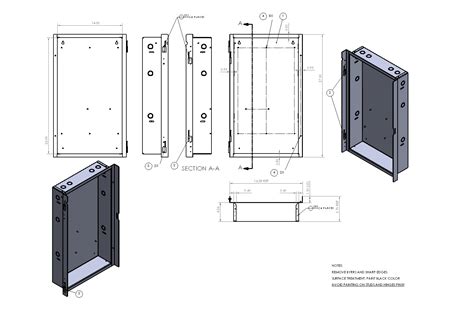

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

In most cases today, homeowners hang the decorative old-looking metal stars on their homes simply because they enjoy and like them. Usually they are 5-pointed and come in various sizes. Sometimes they are hung on the porch wall. Other times you see them hung near the gable, on the garage or on a barn.

A quick DIY process on how I built and welded a simple metal forming tool for making smooth and gentle bends on sheet metal.Follow me on Instagram: https://w. This video will outline 2 different types of metal forming you can do at home in your garage or workshop. The metal forming covered today will be hydraulic . This video shows how to create and form your own sheet metal parts with limited tooling. In this video I show how to make a simple metal brake with a couple . Complex curves can be repeated thousands of times over, by putting a sheet of steel between shaped tooling in a press and applying huge force. The same work that would take a skilled panel.

1. Place the sheet metal in the correct position on the positive die and slide the negative on top! It's like a little metal sandwich! 2. Find a long, metal cylinder that will fit between the two .

Hot-rolled, pickled, and oiled (HRPO) steel is the most common material for tools because it is suitable for most forming applications. Making the tool is a simple process, but first you must consider some very important . In this article we will share the most common and important tools, machines, and techniques for the DIY fabricator. Metal Shaping or forming can only change metal in four .Sheet metal is easy to cut, bend, and form. You can make a ton of different cool stuff with it too! Check out these sheet metal projects to get some ideas.

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-scale.

Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent.A quick DIY process on how I built and welded a simple metal forming tool for making smooth and gentle bends on sheet metal.Follow me on Instagram: https://w. This video will outline 2 different types of metal forming you can do at home in your garage or workshop. The metal forming covered today will be hydraulic .This video shows how to create and form your own sheet metal parts with limited tooling. In this video I show how to make a simple metal brake with a couple .

Complex curves can be repeated thousands of times over, by putting a sheet of steel between shaped tooling in a press and applying huge force. The same work that would take a skilled panel.1. Place the sheet metal in the correct position on the positive die and slide the negative on top! It's like a little metal sandwich! 2. Find a long, metal cylinder that will fit between the two stainless steel rods. Place this cylinder on top of the metal sandwich and place the . Hot-rolled, pickled, and oiled (HRPO) steel is the most common material for tools because it is suitable for most forming applications. Making the tool is a simple process, but first you must consider some very important design factors. In this article we will share the most common and important tools, machines, and techniques for the DIY fabricator. Metal Shaping or forming can only change metal in four ways. You can bend, cut, shrink and stretch metal to form it. Below are the common tools and techniques to perform these tasks. Bending Metal.

Sheet metal is easy to cut, bend, and form. You can make a ton of different cool stuff with it too! Check out these sheet metal projects to get some ideas.

sheet metal layout drawings

sheet metal forming types

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-scale.

Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent.

A quick DIY process on how I built and welded a simple metal forming tool for making smooth and gentle bends on sheet metal.Follow me on Instagram: https://w.

This video will outline 2 different types of metal forming you can do at home in your garage or workshop. The metal forming covered today will be hydraulic .

This video shows how to create and form your own sheet metal parts with limited tooling. In this video I show how to make a simple metal brake with a couple . Complex curves can be repeated thousands of times over, by putting a sheet of steel between shaped tooling in a press and applying huge force. The same work that would take a skilled panel.1. Place the sheet metal in the correct position on the positive die and slide the negative on top! It's like a little metal sandwich! 2. Find a long, metal cylinder that will fit between the two stainless steel rods. Place this cylinder on top of the metal sandwich and place the . Hot-rolled, pickled, and oiled (HRPO) steel is the most common material for tools because it is suitable for most forming applications. Making the tool is a simple process, but first you must consider some very important design factors.

In this article we will share the most common and important tools, machines, and techniques for the DIY fabricator. Metal Shaping or forming can only change metal in four ways. You can bend, cut, shrink and stretch metal to form it. Below are the common tools and techniques to perform these tasks. Bending Metal.Sheet metal is easy to cut, bend, and form. You can make a ton of different cool stuff with it too! Check out these sheet metal projects to get some ideas.

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-scale.

sheet metal forming process pdf

sheet metal forming press dies

If you are starting a re-side project and plan to keep your home’s existing roofing, there is a good rule of thumb for matching siding color to your home’s roof: pair a warm color with another warm color, or a cool color with .

diy sheet metal forming|sheet metal forming types