sheet metal stamping dies pdf The basics of metal stampings. Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers. Parts can be flat and simple . Mild steel sheet. 18 or 20 or 22 gauge. About $30 for a 4'*4' piece. 22 gauge for new Hondas. 18 for old vw pans. 20 gauge for old vw bodies. It's a personal .

0 · stamping dies manufacturing process

1 · stamping die standards and requirements

2 · stamping die clearance

3 · sheet metal stamping at home

4 · sheet metal hole stamping tool

5 · sheet metal forming dies

6 · how transfer metal stamping tools

7 · design tooling for stamping dies

Looking for the best metal bending tools? Look no further than our top picks, including manual, hydraulic, and electrical options.

Sheet Metal Stamping. Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they .Sheet Metal Stamping Dies & Processes. After watching the program and .

Metal stamping is a complex process that can include a number of metal forming processes — blanking, punching, bending, and piercing, to name a few. All of these processes come with .The basics of metal stampings. Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers. Parts can be flat and simple .PAM-STAMP 2G, provides a completely integrated sheet-metal-forming simulation for a wide range of applications. The simulation can show the location of defects such as splits and .Normal metal stamping processes involve driving a sharpened tool steel punch through the sheet or strip material and into a die cavity where the slug or scrap is ejected.

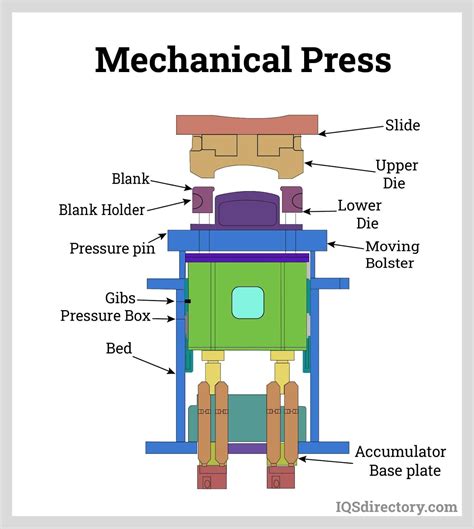

The document then details the essential components of stamping including presses, dies, lubrication and progressive and transfer die technology. It defines common stamping operations like drawing, bending, punching and explains .Sheet Metal Stamping Dies & Processes. After watching the program and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. . Check Pages 1-5 of Sheet Metal Stamping Dies & Processes in the flip PDF version. Sheet Metal Stamping Dies & Processes was published by on 2016-04-15. Find more .

PDF | In sheet metal stamping, it is known that wear is unevenly distributed over the die radius and that multiple wear mechanisms may occur. | Find, read and cite all the research you need on . The increasing use of high-strength steels in sheet metal automotive parts usually brings about shape distortion problems that can not be easily solved compared to stamping parts of conventional . Boljanovic, Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) Topics . PDF download. download 1 file . SINGLE PAGE PROCESSED JP2 ZIP download. download 1 file . TORRENT download. download 13 Files download 6 Original. SHOW ALL. IN COLLECTIONS .ble for die tryout personnel to get an approved HSS stamping if the part design and die process are not optimized. Flange die bend radii must be small in order to minimize springback. . or for mass reduction through a reduction in sheet metal thickness, or gauge. An increase in strength generally leads to reduced ductility or formability .

Stamping dies are the tools that shape and cut sheet metal parts. They are commonly developed using computer-aided design (CAD) software and analytical programs to create and prove-out highly accurate, unambiguous designs. These designs are then translated into stamping dies by skilled craftsmen, known as diemakers. Once these stamping dies are mounted into presses, .bottom side of the hole is relative to the die clearance. Die clearance is the difference between the punch diameter and die diameter. It is usually about 10% of the material thickness. To get a constant diameter through the entire material thickness the .

To sustain the stamping die industry under the current global situation, cost and time are most important factors that need to be focus. In this case study, the main problem of design . Design and Analysis of Stage Progressive Die for a Sheet Metal Component 835 Published By: Blue Eyes Intelligence Engineering and Sciences Publication (BEIESP)Metal stamping uses dies and presses to shape metal sheets. Dies are the main components that do the cutting, punching, and shaping. There are different types of dies, including single station dies, multiple station dies, and progressive dies. Sheet metal stamping is commonly used in the automotive industry due to its high production rates and low costs. The stamping process uses .Sheet Metal Stamping Dies & Processes Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. • • • • • • the terms “ductility” and “formability” are explained the essential components of the stamping process are detailed . Blanking Die Design. See the below drawing for a simple blanking die design. The portion of the sheet metal which is punched through the die is the blank or the component. Blanking Die. Note that the blanking die is provided with an angular relief after a .

Check Pages 1-5 of Sheet Metal Stamping Dies & Processes in the flip PDF version. Sheet Metal Stamping Dies & Processes was published by on 2016-04-15. Find more similar flip PDFs like Sheet Metal Stamping Dies & Processes. Download Sheet Metal Stamping Dies & Processes PDF for free.“Stamping press” Machine tool that performs most sheet metal operations “Stampings”Sheetmetal products. A set of die and punch . Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. Rubber pads can have a general purpose shape, like a membrane. Alternatively, they can be machinedKeywords: knowledge-based engineering, automotive panel stamping, die design. DOI: 10.3722/cadaps.2010.75-87 1 INTRODUCTION Sheet-metal parts are conventionally used to replace expensive cast and forged products in mass production in the automotive industries. Sheet-metal stamping to produce parts with freeform

sheet metal welding test pieces

Download Free PDF. Die Design Fundamentals. José Luis Maldonado Gómez. See full PDF download Download PDF. . This article assesses the tribological performance of new composite tool sets for stamping dies. Four sets of composite countersamples were tested. . The sheet metal working processes is predominantly used in various aspects not .

stamping dies manufacturing process

Discover how sheet metal stamping can change your production line and yield. . Here are the steps involved in setting up for sheet metal stamping: Installation of Dies: The custom-designed dies created in the planning stage are installed into the stamping press. Careful alignment and securing are critical to ensure precision in the stamping .

Sheet metal stamping is used to form three-dimensional parts from flat sheet metal shapes known as ‘blanks’. It is widely used in the car industry to form inner and outer body panels (hoods, doors, fenders etc.) and is used to make appliance panels like oven tops and metal sinks. StampingExtrusion: The extrusion process forces metal through a die with a specifically shaped hole, creating long parts . assisted sheet metal stamping tools—has improved the efficiency and effectiveness of metal stamping operations. 1080 Tri-State Parkway, Gurnee, IL, 60031 • Phone: 847.855.9200 Fax: 847.855.9300 • [email protected] .a part that optimizes all the features that the metal stamping process offers. Material Selection There are many sheet and strip materials to choose from that respond well to metal stamping and forming. However, price and availability can vary greatly and affect the cost and delivery of production metal stampings. There are factors that should be

sheet metal welding conference 2016

High-speed sheet metal stamping is popular because it is economical and quick means of producing intricate, accurate and durable components in large quantities.These dies are set to shape and then used to stamp benchmark parts out of steel sheet. Keywords: Discrete Dies, Rapid Tooling, Sheet Metal Forming, Die Design Introduction There is a need in the sheet metal forming sector of U.S. industry to . 30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John .Ningbo Metal Sharing Supply Chain Management Co., Ltd China Customized Metal Stamping Dies,Customized Sheet Metal Parts supplier & manufacturer,offer low price, high quality Provide Laser Cutting Servic etc. Mr. kinyon . What can I do for you? 8613515883958. Contact Now; Home; About Us .

sheet-metal-forming-processes-and-die-design Identifier-ark ark:/13960/s2gqstq6128 Ocr tesseract 5.0.0-1-g862e Ocr_autonomous true Ocr_detected_lang en . PDF download. download 1 file . SINGLE PAGE . Sheet metal stamping of complex geometries normally involves the use of drawbeads to control the metal flow in the forming die. Drawbeads are, however, often the most tribologically severe part of the stamping dies. Selection of a suitable tribosystem for this type of forming operation depends on parameters such as local contact pressures, sliding speed, .kuat diberikan pada sheet metal untuk menghasilkan tegangan kompresi yang tinggi pada plat untuk menghasilkan deformasi plastis. Jenis-jenis proses penekanan ini adalah : a. Stamping atau Marking. Stamping atau Marking digunakan untuk membuat tanda, simbol, huruf atau bentuk lainnya dengan proses cold forging. b. Heading. Prediction of tool wear pattern for sheet metal stamping die for processing of advanced high strength steel (AHSS) parts is a highly challenging task in automotive applications as there are many .

Die entry line stamping direction blankholder • Other run-offs components. Typically, a dieface contains local elements (sausages) designed to . In sheet metal forming practice, we distinguish five basic modes of deformation: • STRETCHING: The material is expanded in both directions. This mode of deformation is

stamping die standards and requirements

I use both in my Linclone mig, and the .030 in my cold wire feeder for tig work. You can planish it pretty good, or just grind it off. And yes it is easy to grind if you use Argon75/25Co2.

sheet metal stamping dies pdf|sheet metal hole stamping tool