industry standard sheet metal fabrication tolerances Explore the role that precision metal fabrication plays in the aerospace sector, the stringent industry standards and regulations that govern manufacturing, and showcase how precision metal fabrication is shaping the . $46.09

0 · typical sheet metal tolerances

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm steel sheet tolerance chart

Figuring out how to clean vintage metal objects often ends up being a trial-and-error process. The good news is that vintage/antique metal objects are usually pretty easy to clean, provided they are in good condition, .

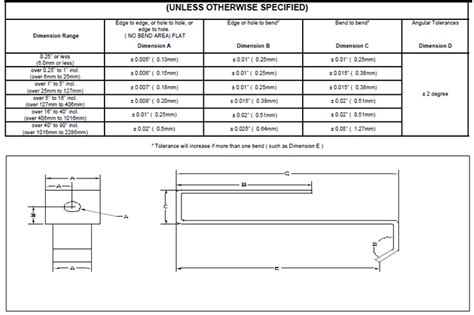

There are three types of sheet metal tolerances: Material, Dimensional, and Geometric. We work with three types of tolerances: Dimensional tolerances: These refer to the variations that are allowed in a part’s physical dimensions. If .

These tolerances are recommended and best practices. We can obtain tighter tolerances (depending on part geometry/ construction), so feel free to contact us for more information or . Explore the role that precision metal fabrication plays in the aerospace sector, the stringent industry standards and regulations that govern manufacturing, and showcase how precision metal fabrication is shaping the . At Pinnacle Precision, meeting the stringent demands of the medical industry is at the core of what we do.Our expert team leverages specialized fabrication processes and medical-grade materials to consistently deliver high-quality, precision medical parts that perform in even the harshest environments.. Our capabilities empower the industry with innovative solutions .

Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about . As raw material, sheet metal has behavioral weirdness. Some of that weirdness, stress in particular, is relieved during manufacturing. The resulting bend angle variation, and sometimes the required adjustment to the flat layout, contributes to the reason that machined parts (typical tolerance of ±0.002 in.) can routinely have tighter .One of the most critical aspects of sheet metal fabrication is managing tolerances, which are the permissible variations in a part's dimensions. Tolerances are essential for ensuring that parts fit together correctly, function as intended, and meet required quality standards. Without precise tolerance control, manufacturers can encounter significant issues such as misalignments, . For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. General Tolerances. For sheet metal fabrication, there are a few general tolerances that the industry uses everywhere.

6) Standard tolerance and standard tolerance class. Sheet metal standard tolerance is any tolerance listed in the national standard to determine the size of the tolerance zone. The standard tolerance level is the level to determine the accuracy of dimensions. The standard tolerance is divided into 20 grades. As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals.In the realm of Neway's expertise in sheet metal fabrication, here's how tolerance considerations influence the choice of thickness: . The industry standards for sheet metal stamping tolerances typically specify dimensional variations allowed in the final stamped parts. Factors like material thickness, part complexity, and the specific .

Overview of Industry Standards in Metal Fabrication Standards about bend radii in metalworking are set out to maintain consistency, quality, and reliability in sheet metal parts. Typically, bend radii are based on the thickness and type of the material, and such guidelines must always be followed to prevent the material from failing and to . Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing . Fabricators can only bend sheet metal so far before damaging it, and we call that smallest possible inner curvature the bend radius (or internal radius.) You can slash your lead time and avoid the high cost of custom tooling by designing your part’s bend radius to 0.030"—the industry standard for sheet metal up to 0.125" (⅛") thick. Last updated on July 15th, 2024 at 10:39 am. At Approved Sheet Metal, we have extensive experience fabricating high-precision sheet metal components and assemblies for aerospace industry customers.. Whether you’re seeking quick-turn prototypes or low-volume productions, ASM works closely with engineers to ensure every aerospace part adheres to the .

Tim Heston, The Fabricator's senior editor, has covered the metal fabrication industry since 1998, starting his career at the American Welding Society's Welding Journal. Since then he has covered the full range of metal fabrication processes, from stamping, bending, and cutting to grinding and polishing.

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool . The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges .Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).

typical sheet metal tolerances

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. . Industry 4.0; New Product Introduction (NPI) Factory and Machinery; . The standard tolerance for bend angles is ± 0.5°, ensuring precision while allowing for minimal variance.utilizing “soft tooling” or standard tooling, turrets lend themselves to both the highly flexible production of prototypes and inexpensive production quantities. Tolerances – The feature to feature tolerance for the turret press is +/-.004”, the punched hole tolerance is +/-.002”.

Now consider 16-gauge mild steel. The sheet has a nominal thickness of 0.059 in., an upper limit of 0.0648 in., and a lower limit of 0.0548 in., giving us a range of 0.010 in. Add this to the 0.002-in. depth-of-penetration variation noted earlier, and .

0.3.1 In this standard only groups B and C are covered. The tolerances for the fabrication of steel railway bridges and allied structures which fall into Group A will be covered in a separate standard. 0.4 This standard keeps in view the practice being followed in . Sheet metal fabrication (bending, cutting, slitting, etc) is a whole other animal as it requires looser tolerances because of the higher variations. The number of variables and the size of variation change depending on how much manual labor vs. use of equipment and automation. . Monitoring processes involved operator quality checks using . What is ISO 2768-1 standard tolerances for sheet metal fabrication? This is the industry standard for covering linear, flatness, radius, determining tolerances, and angular dimensions, and more. At LC Rapid, we validate our sheet metal fabrication services for tolerance classification of ISO 2768-1 fine (metal) and media (plastic). The most .

It plays an essential role in the production of various items we use daily. With a projected industry growth in sheet metal fabrication services of USD 3.52 billion from 2021 to 2026, the importance of sheet metal fabrication is growing in the manufacturing industry. Here's a breakdown of key industries and how they leverage sheet metal . For part sizes without marked tolerance ranges, this standard should be followed. Please note that all tolerance limits are given in mm. Part 1: General Tolerances ISO 2768-1. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). Precision Refined: Improved Workpiece Tolerances with MAV Plate Rolls Unlock the full potential of metal forming with MAV Plate Rolls, highlighted in this informative video from our MAV series. This episode focuses on how the MAV technology significantly improves workpiece tolerances, ensuring unparalleled precision in every roll. In This Video: Precision .

tolerance sheet metal.xls Author: Rick Slocum Created Date: 3/11/2009 8:16:56 AM .

steel plate thickness tolerance chart

bowers sheet metal

bosch dishwasher junction box with power cord

standard sheet metal tolerances chart

Bring a dart board into your game room, and keep it safe with a classic style with the Viper Metropolitan Dartboard Cabinet for steel tip darts! This cabinet will complete the look of your game room with one of four traditional finishes.$184.99

industry standard sheet metal fabrication tolerances|typical sheet metal tolerances