cnc lathe machine line diagram One crucial aspect of understanding CNC machines is delving into their schematic diagrams. In this comprehensive guide, we will explore the ins and outs of CNC machine schematic . Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.

0 · schematic diagram of cnc machine

1 · explain Mcu in cnc

2 · diagram of cnc lathe machine

3 · cnc turning lathe machine

4 · cnc machine labelled diagram

5 · cnc lathe machine specification

6 · cnc lathe headstock

7 · block diagram of cnc machine

I have a number of 20x20 paver step stones in the backyard. Some of these stones have been pushed up by tree roots. So this weekend I removed about a dozen of these step stones to expose the roots to see if I can .

Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at .Train your operators and staff in the proper use and maintenance of CNC lathe machines. Continuous education and training can help to prevent costly mistakes and reduce downtime. .

One crucial aspect of understanding CNC machines is delving into their schematic diagrams. In this comprehensive guide, we will explore the ins and outs of CNC machine schematic .

While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .

CNC Lathe. A CNC lathe is the most updated type of lathe machine discussed in this article. CNC machines are integrated with modern computer numeric control systems (CNC). These systems allow users to add a CAD/CAM program to . In this guide, we'll preview the 8 pivotal parts of a CNC lathe machine, provide proof of their significance, and give you a preview of their integral role in the machining process. CNC lathe machines signify the .

schematic diagram of cnc machine

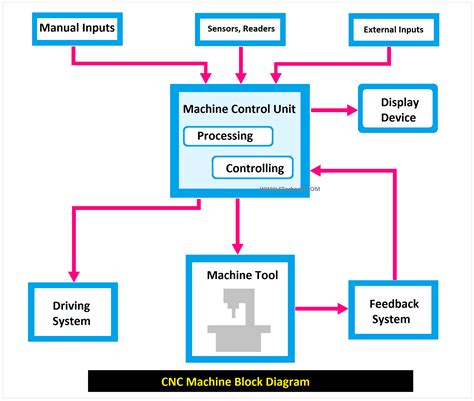

In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit .

explain Mcu in cnc

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing .

Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at distributors such as Amazon.Train your operators and staff in the proper use and maintenance of CNC lathe machines. Continuous education and training can help to prevent costly mistakes and reduce downtime. By understanding a CNC lathe machine diagram and its components,operators and machinists can work more efficiently.

A CNC lathe is a fully automated machine capable of precise turning and drilling operations. It follows G-code programming intended for subtractive manufacture (cutting) and starts with either a suitable material blank or a preform.One crucial aspect of understanding CNC machines is delving into their schematic diagrams. In this comprehensive guide, we will explore the ins and outs of CNC machine schematic diagrams and provide a detailed analysis of each component.

While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts.

CNC Lathe. A CNC lathe is the most updated type of lathe machine discussed in this article. CNC machines are integrated with modern computer numeric control systems (CNC). These systems allow users to add a CAD/CAM program to command the machine. In turn, the CNC lathe automatically operates according to the input. In this guide, we'll preview the 8 pivotal parts of a CNC lathe machine, provide proof of their significance, and give you a preview of their integral role in the machining process. CNC lathe machines signify the evolution of manufacturing.In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.

diagram of cnc lathe machine

Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at distributors such as Amazon.Train your operators and staff in the proper use and maintenance of CNC lathe machines. Continuous education and training can help to prevent costly mistakes and reduce downtime. By understanding a CNC lathe machine diagram and its components,operators and machinists can work more efficiently.

A CNC lathe is a fully automated machine capable of precise turning and drilling operations. It follows G-code programming intended for subtractive manufacture (cutting) and starts with either a suitable material blank or a preform.One crucial aspect of understanding CNC machines is delving into their schematic diagrams. In this comprehensive guide, we will explore the ins and outs of CNC machine schematic diagrams and provide a detailed analysis of each component.While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts.

CNC Lathe. A CNC lathe is the most updated type of lathe machine discussed in this article. CNC machines are integrated with modern computer numeric control systems (CNC). These systems allow users to add a CAD/CAM program to command the machine. In turn, the CNC lathe automatically operates according to the input. In this guide, we'll preview the 8 pivotal parts of a CNC lathe machine, provide proof of their significance, and give you a preview of their integral role in the machining process. CNC lathe machines signify the evolution of manufacturing.In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine.

electrical boxes meter metal door

electrical boxes for lap siding

A box plot is an easy method to display the set of data distribution in terms of quartiles. Visit BYJU’S to learn its definition, and learn how to find out the five-number summary of box plot with Examples.

cnc lathe machine line diagram|explain Mcu in cnc