drywall over airtight electrical box At the time, they were called “vapor tight” boxes, and they were designed to reduce air movement through wall or ceiling cavities by sealing the box to the wall or ceiling air barrier; they also required sealing the electrical . CNC, an acronym for Computer Numerical Control, has revolutionized the woodworking industry. The mechanization and precision it offers stand unparalleled. Now, let us take you on a whirlwind tour of the bustling, dynamic world of wholesale wood CNC machine manufacturers.

0 · how to hang airtight drywall

1 · how to airtight drywall

2 · airtight metal electrical box

3 · airtight electrical box installation

4 · airtight drywall walls

5 · airtight drywall sealing

6 · airtight drywall installation

7 · air tight electrical boxes

CNC machining is the use of pre-programmed control tools and equipment applications to manufacture products. Like robots, CNC machines can help humans complete specific tasks. Compared with manual labor, CNC machining can improve precision, speed up production, improve safety and efficiency, and most importantly, save costs.

Electric boxes can be made air tight by caulking or sealing all openings in the box (including around wire penetrations) and by sealing the face of the box to the drywall. Specially . At the time, they were called “vapor tight” boxes, and they were designed to reduce air movement through wall or ceiling cavities by sealing the box to the wall or ceiling air barrier; they also required sealing the electrical .Three ways to make a box airtight. The cheapest way to seal an electrical box is to caulk or foam the holes in the back and to seal the perimeter to the drywall. This method is fine for a garage . Electrical Boxes. Sealing the holes created by electrical boxes eliminates a major source of air movement into exterior walls.

how to hang airtight drywall

how to airtight drywall

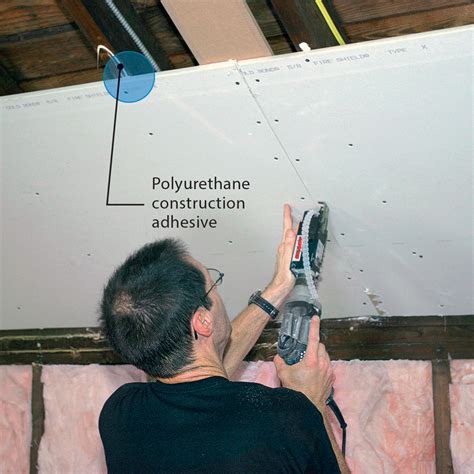

Drywall can be an effective air barrier, but only if you are careful to stop air from moving through electrical outlets, light fixtures, and other holes that connect living space to wall and ceiling . They even have a gasket to squeeze the polyethylene between the box flange and the drywall, making an airtight seal. According to the National Research Council of Canada, up to 30 litres of water can go through each . Wondering how installers who use the plastic airtight electrical boxes with the foam gasket (e.g. Nutek brand), deal with either 5/8″ drywall or even double 5/8 drywall which is .

You’ll also need airtight electrical boxes. Most include a flange that helps to seal the gap between the box and the drywall. Some airtight boxes have flanges with an integral gasket, while others have flanges that are designed to be caulked.

Electric boxes can be made air tight by caulking or sealing all openings in the box (including around wire penetrations) and by sealing the face of the box to the drywall. Specially designed airtight electric boxes with flexible boot seals at wire penetrations and a gasketed flange at the face can also provide air barrier continuity. At the time, they were called “vapor tight” boxes, and they were designed to reduce air movement through wall or ceiling cavities by sealing the box to the wall or ceiling air barrier; they also required sealing the electrical wires where they enter the box.Three ways to make a box airtight. The cheapest way to seal an electrical box is to caulk or foam the holes in the back and to seal the perimeter to the drywall. This method is fine for a garage shop. A better way is to use a premade electrical box cover, usually made from EPS foam, that wraps around the box and is caulked and foamed in place.

aluminum cnc aircraft spare parts factory

airtight metal electrical box

aluminum boat fuel tank fabrication

Electrical Boxes. Sealing the holes created by electrical boxes eliminates a major source of air movement into exterior walls.Drywall can be an effective air barrier, but only if you are careful to stop air from moving through electrical outlets, light fixtures, and other holes that connect living space to wall and ceiling cavities. The combination of the drywall, framing, and caulk, foam, and sealant make up the air barrier assembly. They even have a gasket to squeeze the polyethylene between the box flange and the drywall, making an airtight seal. According to the National Research Council of Canada, up to 30 litres of water can go through each electrical box over the course of a winter. Wondering how installers who use the plastic airtight electrical boxes with the foam gasket (e.g. Nutek brand), deal with either 5/8″ drywall or even double 5/8 drywall which is common in sound dampening installations.

The boxes are plastic with self sealing gaskets where the wires come through and they have a gasketed flange on the face. When the vapour barrier is put over the wall, and the drywall is fastened into place, the drywall will trap the vapour barrier against the gasket, making an air tight electrical box.

Running wires into airtight electrical boxes can be a pain. When the wires are stripped from their casing, one of them inevitably catches a rib on the back side of the wire-retention tab or bends off in a different direction than the rest of the wires because of the pressure required to lift the tab.You’ll also need airtight electrical boxes. Most include a flange that helps to seal the gap between the box and the drywall. Some airtight boxes have flanges with an integral gasket, while others have flanges that are designed to be caulked. Electric boxes can be made air tight by caulking or sealing all openings in the box (including around wire penetrations) and by sealing the face of the box to the drywall. Specially designed airtight electric boxes with flexible boot seals at wire penetrations and a gasketed flange at the face can also provide air barrier continuity.

At the time, they were called “vapor tight” boxes, and they were designed to reduce air movement through wall or ceiling cavities by sealing the box to the wall or ceiling air barrier; they also required sealing the electrical wires where they enter the box.Three ways to make a box airtight. The cheapest way to seal an electrical box is to caulk or foam the holes in the back and to seal the perimeter to the drywall. This method is fine for a garage shop. A better way is to use a premade electrical box cover, usually made from EPS foam, that wraps around the box and is caulked and foamed in place. Electrical Boxes. Sealing the holes created by electrical boxes eliminates a major source of air movement into exterior walls.

airtight electrical box installation

Drywall can be an effective air barrier, but only if you are careful to stop air from moving through electrical outlets, light fixtures, and other holes that connect living space to wall and ceiling cavities. The combination of the drywall, framing, and caulk, foam, and sealant make up the air barrier assembly.

They even have a gasket to squeeze the polyethylene between the box flange and the drywall, making an airtight seal. According to the National Research Council of Canada, up to 30 litres of water can go through each electrical box over the course of a winter.

Wondering how installers who use the plastic airtight electrical boxes with the foam gasket (e.g. Nutek brand), deal with either 5/8″ drywall or even double 5/8 drywall which is common in sound dampening installations.

The boxes are plastic with self sealing gaskets where the wires come through and they have a gasketed flange on the face. When the vapour barrier is put over the wall, and the drywall is fastened into place, the drywall will trap the vapour barrier against the gasket, making an air tight electrical box.

aluminum boat fabrication seattle

By choosing a stainless steel litter box, you can contribute to reducing plastic waste and promote a more eco-friendly lifestyle. On the other hand, plastic litter boxes remain a popular option due to their affordability and wide availability.

drywall over airtight electrical box|how to airtight drywall