electric vehicle battery box adhesive Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how. For a size-6 screw, use a 7/64-inch drill bit, and for a size-8 screw, use a 1/8-inch drill bit. If you are using a size-10 screw, the recommended pilot hole size is 9/64 inches. It is important to note that the pilot hole should be drilled before inserting the sheet metal screw.

0 · Solutions for Electric Vehicle Battery Applications

1 · Seven Ways Adhesives Push EV Design Forward

2 · Electric Vehicles and the Growing Significance of

3 · Electric Vehicle and Electrification Adhesive Solutions

4 · EV Battery Solutions

5 · EV Battery Pack Integration

6 · EV Battery Box Bonding Adhesive: A Comprehensive Guide

7 · Adhesives for Electric Vehicles

8 · Adhesives for EV Battery Applications: Q&A

9 · Adhesive Solutions for EV Batteries

Determining the correct size drill bit for a specific screw is essential for ensuring a secure and professional-looking result. Using the wrong size drill bit can lead to stripped screw heads, weak connections, and an .

Manufacturers can ensure electric vehicles’ long-term reliability and safety by choosing the suitable bonding adhesive for EV battery boxes, contributing to a greener, more .Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.

At Ellsworth Adhesives, we provide innovative adhesive solutions tailored to meet the rigorous demands of EV and electrification battery systems. Our products are engineered to offer .3.311.37.29

3.92,458.442.81

Bonding Electric Vehicle Battery Boxes. Adhesives are often used to bond and seal the lid of the battery pack to the body. High-performance plastics help keep the battery lightweight and . We have a wide range of adhesive and tape technologies that can be applied to specific EV Battery Pack needs. For example, we are working on the second generation of .AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, .

Solutions for Electric Vehicle Battery Applications

Looking for the right EV battery pack integration adhesives? Fortunately, Bostik formulates innovative, structural adhesives designed to make meeting evolving processes easy.New battery designs are required to fuel the electric vehicle revolution. Critical end-consumer perceptions of range anxiety, as well as price and safety concerns, must be addressed through batteries that offer reliable and safe operation of .

Here are seven ways adhesives— including some that also function as a thermal inter-face material (TIM)—are helping advance EV design. One of the biggest challenges in designing .

Adhesives, sealants, gaskets, and thermal materials play an essential role in several areas of the EV battery’s technology, including the battery cells, battery modules, battery packs, and the battery management system .

Manufacturers can ensure electric vehicles’ long-term reliability and safety by choosing the suitable bonding adhesive for EV battery boxes, contributing to a greener, more sustainable future.

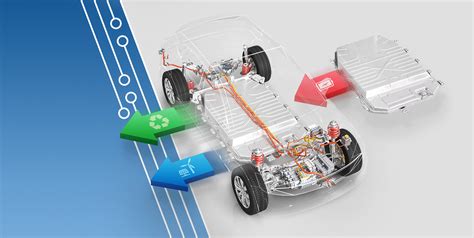

Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.At Ellsworth Adhesives, we provide innovative adhesive solutions tailored to meet the rigorous demands of EV and electrification battery systems. Our products are engineered to offer thermal management, fire protection, and environmental resilience, ensuring every component within the battery system operates at peak efficiency.Bonding Electric Vehicle Battery Boxes. Adhesives are often used to bond and seal the lid of the battery pack to the body. High-performance plastics help keep the battery lightweight and durable, as well as offering vibration, impact and weather resistance.

We have a wide range of adhesive and tape technologies that can be applied to specific EV Battery Pack needs. For example, we are working on the second generation of more conformable dielectric tapes for electrical insulation.AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids.Looking for the right EV battery pack integration adhesives? Fortunately, Bostik formulates innovative, structural adhesives designed to make meeting evolving processes easy.

New battery designs are required to fuel the electric vehicle revolution. Critical end-consumer perceptions of range anxiety, as well as price and safety concerns, must be addressed through batteries that offer reliable and safe operation of the car in tandem with fast charging.Here are seven ways adhesives— including some that also function as a thermal inter-face material (TIM)—are helping advance EV design. One of the biggest challenges in designing batteries for plug-in hybrids and EVs is thermal management of the battery pack. Battery components must oper-ate within a window of 15-60°C during operation and charging. Adhesives, sealants, gaskets, and thermal materials play an essential role in several areas of the EV battery’s technology, including the battery cells, battery modules, battery packs, and the battery management system (BMS).

Manufacturers can ensure electric vehicles’ long-term reliability and safety by choosing the suitable bonding adhesive for EV battery boxes, contributing to a greener, more sustainable future.Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.At Ellsworth Adhesives, we provide innovative adhesive solutions tailored to meet the rigorous demands of EV and electrification battery systems. Our products are engineered to offer thermal management, fire protection, and environmental resilience, ensuring every component within the battery system operates at peak efficiency.

Bonding Electric Vehicle Battery Boxes. Adhesives are often used to bond and seal the lid of the battery pack to the body. High-performance plastics help keep the battery lightweight and durable, as well as offering vibration, impact and weather resistance. We have a wide range of adhesive and tape technologies that can be applied to specific EV Battery Pack needs. For example, we are working on the second generation of more conformable dielectric tapes for electrical insulation.

AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids.Looking for the right EV battery pack integration adhesives? Fortunately, Bostik formulates innovative, structural adhesives designed to make meeting evolving processes easy.

New battery designs are required to fuel the electric vehicle revolution. Critical end-consumer perceptions of range anxiety, as well as price and safety concerns, must be addressed through batteries that offer reliable and safe operation of the car in tandem with fast charging.

Seven Ways Adhesives Push EV Design Forward

Here are seven ways adhesives— including some that also function as a thermal inter-face material (TIM)—are helping advance EV design. One of the biggest challenges in designing batteries for plug-in hybrids and EVs is thermal management of the battery pack. Battery components must oper-ate within a window of 15-60°C during operation and charging.

metal fabrication ns

metal fabrication oxnard

metal fabrication newton abbot

Electric Vehicles and the Growing Significance of

The early Craftsman wrenches were made of chrome vanadium steel, and the growth of the Craftsman brand coincided with the larger picture of the growing importance of alloy steel in tool making. In 1933 Sears captured this sentiment by making "Vanadium" a sub-brand in its "Craftsman Vanadium" wrench series.

electric vehicle battery box adhesive|Electric Vehicles and the Growing Significance of