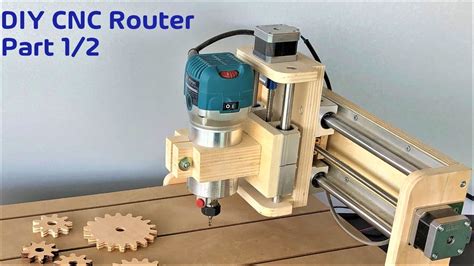

build a cnc milling machine with dc motors A desktop CNC machine is the perfect tool to make small to medium sized parts and projects from a nearly infinite number of materials. The Sienci Mill One is specifically designed to be simple, easy to use, require a minimal number of components, and provide the highest degree of performance and rigidity compared to other machines in its price .

Junction boxes come in various sizes, and the screw size depends on the specific box size. For smaller junction boxes, #6 (3.5mm) screws with a length of 0.75 to 1 inch (19 to 25mm) are commonly used.

0 · sienci mill one cnc machine

1 · how to make a cnc machine

2 · how to build a cnc

3 · diy cnc milling machine

4 · diy cnc machine kit

5 · diy cnc machine

6 · build your own cnc machine

7 · build a cnc machine from scratch

$179.99

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal .A desktop CNC machine is the perfect tool to make small to medium sized parts and projects from a nearly infinite number of materials. The Sienci Mill One is specifically designed to be simple, . CNC milling machine conversion using an Arduino Mega 2560 to control brushless DC motors powered by the ODrive motor controller. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.A desktop CNC machine is the perfect tool to make small to medium sized parts and projects from a nearly infinite number of materials. The Sienci Mill One is specifically designed to be simple, easy to use, require a minimal number of components, and provide the highest degree of performance and rigidity compared to other machines in its price .

CNC milling machine conversion using an Arduino Mega 2560 to control brushless DC motors powered by the ODrive motor controller. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine. There are three stepping motors and .

why is amo poping in my metal box

And here I've put together a circuit that I think is the absolute cheapest and easiest way to control stepper motors with step and direction signals. It works with many of the free or low cost softwares that produce step and direction signals through the parallel printer port. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach. Stepper motors are DC motors that move in steps. They have multiple coils that are organized in groups called "phases". By energizing each phase in sequence, the motor will rotate, one step at a time. With computer controlled stepping you can achieve very precise positioning and/or speed control. Learn how to build your own CNC machine from scratch with our step-by-step guide. Discover essential components, detailed assembly instructions, and expert tips for creating a powerful, customized CNC machine tailored to your needs.

I designed and built my own Bridgeport milling machine CNC controls (X, Y, and Z axes). The design was based on various elements I learned about from the similar projects others have attempted, with a few of my own improvisations and innovations. Setting up a Brushless DC Motor (BLDC) on the ODrive position and speed controller. Stepping through first-time install and setup of all elements to get the motor up and running.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.A desktop CNC machine is the perfect tool to make small to medium sized parts and projects from a nearly infinite number of materials. The Sienci Mill One is specifically designed to be simple, easy to use, require a minimal number of components, and provide the highest degree of performance and rigidity compared to other machines in its price .

CNC milling machine conversion using an Arduino Mega 2560 to control brushless DC motors powered by the ODrive motor controller.

Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine. There are three stepping motors and .

And here I've put together a circuit that I think is the absolute cheapest and easiest way to control stepper motors with step and direction signals. It works with many of the free or low cost softwares that produce step and direction signals through the parallel printer port. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach. Stepper motors are DC motors that move in steps. They have multiple coils that are organized in groups called "phases". By energizing each phase in sequence, the motor will rotate, one step at a time. With computer controlled stepping you can achieve very precise positioning and/or speed control. Learn how to build your own CNC machine from scratch with our step-by-step guide. Discover essential components, detailed assembly instructions, and expert tips for creating a powerful, customized CNC machine tailored to your needs.

I designed and built my own Bridgeport milling machine CNC controls (X, Y, and Z axes). The design was based on various elements I learned about from the similar projects others have attempted, with a few of my own improvisations and innovations.

sienci mill one cnc machine

The specific screw size that is required will be specified in the installation instructions for the electrical box. Junction boxes are typically secured with 6 screws. 6 screws are 0.113 inches in diameter and have a thread pitch of 1.00 threads per inch.Junction boxes like that one are 8-32. Ground screws are 10-32. Also, you could buy a ceiling hugger style fan instead of a stem mounted one, .

build a cnc milling machine with dc motors|build a cnc machine from scratch