build a sheet metal bender Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until . Waste reduction with factory fabricated dimensional material. Downweight: reduce dead load with lightweight aluminum. Easy plenum access. Interior and exterior applications. Compatible with industry standard lighting, HVAC, speaker, fire safety, and security services. Standard patterns shown. Perforations not available on real wood veneer.

0 · make your own metal bender

1 · homemade sheet metal press brake

2 · homemade sheet metal brake plans

3 · homemade sheet metal brake

4 · homemade sheet metal bending brake

5 · homemade sheet metal bender plans

6 · homemade sheet metal bender

7 · homemade metal bender plans

eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials.

make your own metal bender

At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). In this video i have made a sheet metal bending tools. This homemade tool can be use for small fabrication projects, This sheet metal bender only for thin metal sheet, this is. In this video I'll be building a sheet metal bender. This bender is designed to bolt to my welding bench, using 5 each 3/4" Whitworth studs. The bender measu.Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until .

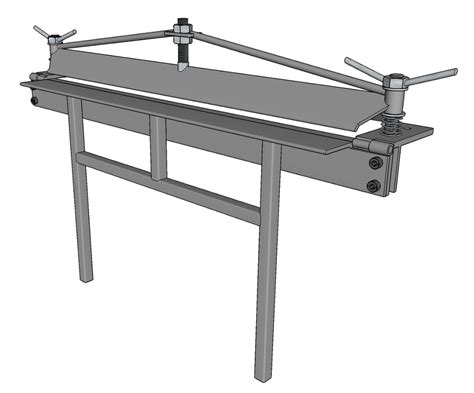

In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and . here you get the plans of my awesome DIY Sheet Metal Bender which you can see on my youtube channel www.youtube.com/c/themetalist. Your are able to bend Metal with 750 mm of length. You could also build it in 1 m. .This tutorial teaches you how to build your own basic sheet metal bender to help you bend those sheet metals into the right shape for your projects. The video creator ‘TheEnginesmith’ shares that he has spent about nzd .

This document provides instructions for building a DIY sheet metal and acrylic bender using basic woodworking tools and materials. The bender allows precise bending of sheet metal up to .A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal .A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle).

In this video i have made a sheet metal bending tools. This homemade tool can be use for small fabrication projects, This sheet metal bender only for thin metal sheet, this is. In this video I'll be building a sheet metal bender. This bender is designed to bolt to my welding bench, using 5 each 3/4" Whitworth studs. The bender measu.Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent. Since it almost always bends crooked, I end up rebending - and generally just .

In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and hinged handle. here you get the plans of my awesome DIY Sheet Metal Bender which you can see on my youtube channel www.youtube.com/c/themetalist. Your are able to bend Metal with 750 mm of length. You could also build it in 1 m. The maximum thickness of steel should be not thicker than 1.5-2 mm.

This tutorial teaches you how to build your own basic sheet metal bender to help you bend those sheet metals into the right shape for your projects. The video creator ‘TheEnginesmith’ shares that he has spent about nzd (approximately US) on the materials.

This document provides instructions for building a DIY sheet metal and acrylic bender using basic woodworking tools and materials. The bender allows precise bending of sheet metal up to 2mm thick and acrylic up to 10mm thick.

A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal brakes can be expensive, but building one yourself from repurposed materials can be both cost-effective and efficient for smaller projects. Materials and Tools .

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). In this video i have made a sheet metal bending tools. This homemade tool can be use for small fabrication projects, This sheet metal bender only for thin metal sheet, this is. In this video I'll be building a sheet metal bender. This bender is designed to bolt to my welding bench, using 5 each 3/4" Whitworth studs. The bender measu.

Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent. Since it almost always bends crooked, I end up rebending - and generally just .

homemade sheet metal press brake

In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and hinged handle. here you get the plans of my awesome DIY Sheet Metal Bender which you can see on my youtube channel www.youtube.com/c/themetalist. Your are able to bend Metal with 750 mm of length. You could also build it in 1 m. The maximum thickness of steel should be not thicker than 1.5-2 mm.

This tutorial teaches you how to build your own basic sheet metal bender to help you bend those sheet metals into the right shape for your projects. The video creator ‘TheEnginesmith’ shares that he has spent about nzd (approximately US) on the materials.This document provides instructions for building a DIY sheet metal and acrylic bender using basic woodworking tools and materials. The bender allows precise bending of sheet metal up to 2mm thick and acrylic up to 10mm thick.A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal brakes can be expensive, but building one yourself from repurposed materials can be both cost-effective and efficient for smaller projects. Materials and Tools .

metal fabricators in philadelphia pa

Arlington CP3540-1C 3-1/2 Inch and 4 Inch Ceiling Box Cover. Arlington's CP3540-1 covers unused 3-1/2 inch and 4 inch round and octagonal boxes prior to the installation of a fan or fixture. Non-rusting, paintable plastic.

build a sheet metal bender|homemade sheet metal bender