metal fabrication examples The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . Galvanized steel is a type of steel that has been coated with a metallic layer to protect the base steel substrate from corrosion. Types of galvanized coatings include zinc (Zn), aluminum (Al), combinations of zinc & aluminum, and combinations of zinc & aluminum & magnesium.

0 · what are fabricated metal products

1 · types of metalworking

2 · types of metal processing

3 · products made by fabrication

4 · manufacturing methods for metals

5 · manufacture of fabricated metal products

6 · different methods of fabrication

7 · basic metal fabrication

Converters that are used to continuously translate electrical input to mechanical output or vice versa are called electric machines. The process of translation is known as electromechanical .

what are fabricated metal products

metal stand bracket for 4x4 post

types of metalworking

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, . See moreChoosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See moreThis guide provides a basic understanding of metal fabrication, the different methods, and considerations for choosing a fabricator. For more . See more

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, . Metal fabrication is easy to understand at an elementary level. With that being said, the numerous metal fabrication processes involved are each unique and highly detailed. Knowing the basic tenets of each is key to .

Metal fabrication is the process of turning raw metals into pre-made shapes for assembly use. For example, the panels that comprise the frame of an automobile are made through custom metal fabrication processes, which .Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] process involving the creation of machines, parts, and structures from various raw materials. Typically, a .

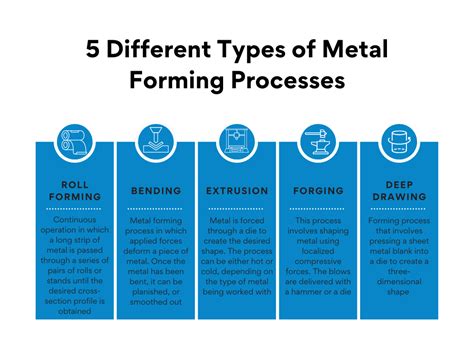

metal steel drawer door file cabinet

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .Parts made in Protolabs’ 3D printing, sheet metal fabrication, and machining processes have minimum and maximum size restrictions. Since part envelopes are continually expanding at Protolabs, please look at the design guidelines .In this list, you’ve encountered popular types of metal fabrication like casting, forging, metal stamping, cutting, extrusion, and welding. As mentioned before, these methods are used for crafting different metal components that are used .Three of the most common types of metal fabrication include structural, commercial and industrial. Structural fabrication refers to metalworking done as part of the building process. The construction industry is one of the largest .

Metal Fabrication and Processes. Every industry has different needs, and each fabricated piece has its own specifications. The metal fabrication process might include a variety of methods to reduce, shape and join . Sheet metal fabrication is also convenient and cost-effective. It’s an affordable way to design and mass-produce high-quality products. And because of their light weight, sheet metal products are easier and less .Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves .

Examples of Metal Fabrication Products 14 July, 2023 Metal fabricated products are adaptable and long-lasting products made through the skillful process of shaping, cutting, and assembling diverse metal components.

At Tuckey Metal Fabricators, we've specialized in a variety of metal fabrication processes for customers across various industries. Learn more on our blog! 24-Hour Emergency Care; . For example, the panels that comprise the frame of an automobile are made through custom metal fabrication processes, which are usually performed at a fabrication .

For example, if a metal fabricated piece is to be produced via CNC machining, a solid bar or tube is often used. However, since precision sheet metal fabrication constitutes a significant portion of the metal fabrication industry, the preferred raw material form is often a flat or rectangular piece of sheet or plate metal.

A place to show off your metal working skills from bending to welding. If it's made of metal and you built it or modified it we want to see it. This includes art, vehicle modification, structures, and anything metal

Metal Fabricators create the components and parts of products that are made out of metal. Skills relevant to this position and found on sample resumes include building patio fencing to scale of blueprints taken from customers, building steering columns for city works vehicles, cleaning and preparing parts for powder coatings, and inspecting and packaging finished parts. Fabrication plays a significant role in metalworking, where various processes are used to shape and assemble metal components for industrial applications. Examples of Fabrication in Real-World Applications 1- Steel Fabrication: In construction, steel beams and columns are fabricated to provide structural support for buildings.Metal Fabricator resume education example. A Metal Fabricator typically needs to have a high school diploma or equivalent, although some employers may prefer applicants with a certificate or two-year degree in welding technology or a related field. . Certificate in Metal Fabrication – ABC College, Anytown, USA (2017) High School Diploma .Portfolio of custom fabrications completed with Poma Architectural Metals. These work examples show expert metal fabrication for architectural designs.

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] . Welder-produced products, often referred to as weldments, are examples of fabrication. Boilermakers originally specialized in fabricating boilers, .

I understand this will vary from location to location and from product to product, but was wondering if anyone could give some 'common' examples of. per ISO/TS 16949 Clause 7.2.1 (c). 'statutory and regulatory requirements related to the product' Product is automotive in nature, mostly. For decades, metal fabricators have equated productivity to effort—how to get more parts per hour out of a press brake or cut faster with an ultrahigh-powered fiber laser. Still, “focused effort” is last on Meyer’s list; “commitment to excellence” and “intelligent planning” come before it—for good reason. . The example shows . Considerations Before Outsourcing Metal Fabrication. A business must spend time determining its specific metal fabrication needs. This involves identifying the type and complexity of projects it will be outsourcing. For .

Give examples of past projects you have worked on, and any achievements you have had in metal fabrication. Highlight your problem- solving skills and ability to work in a team. Show your enthusiasm for the position and explain why you would be a great fit for the company.Some fabricated metal product examples include bolts and screws, cutlery, pipe fittings, car parts and even hand tools. However, it is difficult for many of us to understand what precision metal fabrication entails, as well as all of the areas .

Metal fabricators typically work with a range of raw materials that may include different types of metal such as plate metal, expanded metal, welding wires and rods, and cast metal. . Some example fabrication processes include: #1. Burning and Cutting. Burning and cutting tools are used to cut through raw materials, with the most common .

A Sheet Metal Worker is a highly skilled construction and fabrication professional who works with metal materials to create and assemble products. When crafting a resume for a Sheet Metal Worker position, it’s important to include an objective .

The metal fabrication industry is expected to experience significant transformation in the coming years. Take into the following trends to go ahead in the market! 3D printing and additive manufacturing; 3D printing or additive manufacturing utilizes a CAD model or a digital 3D model to create a three-dimensional object. It deposits, joins, or .

For example, an effective resume objective might read: "Experienced sheet metal mechanic seeking to apply 10+ years of expertise in welding and fabrication to a role with ABC Company." This example communicates relevant skills and . A Sheet Metal Worker should have metal fabrication skills as they are required to measure, cut, bend, and shape sheets of metal into various parts and structures. This skill is crucial for a resume objective because it demonstrates the candidate's ability to perform essential job duties, which include designing and creating metal parts for .Fabrication Examples. Facebook. 0. Fabrication Examples. Fabricated parts. Custom exhaust duct work to carry chiller system heat out of the building in the summer and inside in the winter. . KAD Industries is a local sheet metal fabrication and machining services provider serving western Massachusetts, Connecticut, and surrounding areas. .

Before a raw metal material can be used for manufacture and assembly, it still needs to undergo different types of metal fabrication techniques. These processes can vary, depending on the purpose of the metal, but they can nevertheless be found in a number of structural, industrial, or decorative applications. 1. Rolling Metal. In the fabrication sector, rolling metal is among the most often used techniques. This procedure will be helpful particularly when dealing with sheet metal. Rolling reduces thickness by passing metal stock between two rollers, therefore guaranteeing consistency and strength. Large-scale projects like manufacturing steel beams .If you want to see more build videos, please Subscribe, Like, & Comment. Support more content production by buying some cool CCS merch: https://store.classic. Metal Fabrication Cover Letter. James Brown. 238 Broadway. New York. NY . United States. To. The HR Manager. XYZ Company. 354 F 63 rd Street. New York. NY 10022. United States. Subject- Application for the position of Metal Fabrication. Dear. I have always delivered my best in fulfilling the requirements of the client in the fabrication tasks .

Sheet metal hems have four main types. Each type is used for a particular purpose. In this section, we will discuss open, closed, roll and teardrop hems, their characteristics and uses in different industries. It is made by bending the metal sheet’s edge back onto itself without fully closing it.Steel is grouped into four categories: 1. Carbon steel– Carbon steel has a higher concentration of carbon than other types of steel (up to 2.5% carbon), which adds to carbon steel’s strength. Carbon steel is commonly used to make construction materials, tools, automotive components, and more. 2. Alloy . See more

metal fabrication examples|types of metalworking