cnc machine change reference point To set the home position, you need to identify the reference point on each axis. This can be done by manually moving the machine's spindle or tool to a known position, . Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to .

0 · unity cnc reference point

1 · setting a reference point in cnc

2 · reference point in cnc

3 · doosan cnc reset reference point

4 · doosan cnc machine reference position

5 · doosan cnc change reference position

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.

unity cnc reference point

jackie kennedy metal sheet

When you send the machine to the first refernce position with G28 in absolute mode (G90) the machine moves first to the part zero (G54 or G92) and then to the machine .The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning. Place an empty tool holder in the Tool Change Pot that is in the Tool Change Ready position, one having an end face that will allow easy measurement of the distance from . To set the home position, you need to identify the reference point on each axis. This can be done by manually moving the machine's spindle or tool to a known position, .

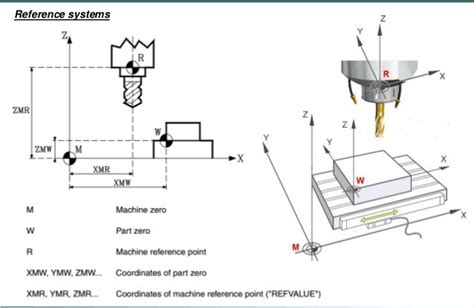

Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and .

Generally speaking, there is no need to change or calibrate the reference point after the machine is installed and commissioned, but it is necessary in the following cases: (1) when an axis of the scale or encoder is . Grid shift lets you make small adjustments in the primary (G28) zero return position, but G30 lets you set any point on the machine as a "second" zero point. Grid shift is only good . Almost all current model CNC machine tools have a special reference position. For machines having Fanuc or Fanuc-compatible controls, this special position is called the zero .During G28 reference point return command machine, first reaches intermediate-point rapidly (G00), then it moves rapidly to reference-point position. Programming G28 X(U) Z(W) X, Z absolute intermediate point position. U, W .

Setting a reference point in CNC is one of the most critical steps in the machining process. It establishes the starting point for all machining operations, ensuring that the machine knows precisely where to position the tool relative to the workpiece.

When you send the machine to the first refernce position with G28 in absolute mode (G90) the machine moves first to the part zero (G54 or G92) and then to the machine zero position. When you send it in incremental mode it goes direct to the machine zero position.The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning. Place an empty tool holder in the Tool Change Pot that is in the Tool Change Ready position, one having an end face that will allow easy measurement of the distance from table to end face, or table to the underside of the Tool Change Ring.

setting a reference point in cnc

To set the home position, you need to identify the reference point on each axis. This can be done by manually moving the machine's spindle or tool to a known position, usually the machine's limit switches or fixed physical stops. Once you reach these positions, you can set them as the home position. 3. Configuring the Home Position.Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools. Generally speaking, there is no need to change or calibrate the reference point after the machine is installed and commissioned, but it is necessary in the following cases: (1) when an axis of the scale or encoder is replaced, the . Grid shift lets you make small adjustments in the primary (G28) zero return position, but G30 lets you set any point on the machine as a "second" zero point. Grid shift is only good for +/- one full turn of the pulse coder.

Almost all current model CNC machine tools have a special reference position. For machines having Fanuc or Fanuc-compatible controls, this special position is called the zero return position. Other names for the machine’s reference position include the home position, grid zero, and machine origin.

During G28 reference point return command machine, first reaches intermediate-point rapidly (G00), then it moves rapidly to reference-point position. Programming G28 X(U) Z(W) X, Z absolute intermediate point position. U, W incremental intermediate point position. Examples. For following exmaples suppos actual referece-point position on your . Setting a reference point in CNC is one of the most critical steps in the machining process. It establishes the starting point for all machining operations, ensuring that the machine knows precisely where to position the tool relative to the workpiece.

When you send the machine to the first refernce position with G28 in absolute mode (G90) the machine moves first to the part zero (G54 or G92) and then to the machine zero position. When you send it in incremental mode it goes direct to the machine zero position.The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning. Place an empty tool holder in the Tool Change Pot that is in the Tool Change Ready position, one having an end face that will allow easy measurement of the distance from table to end face, or table to the underside of the Tool Change Ring. To set the home position, you need to identify the reference point on each axis. This can be done by manually moving the machine's spindle or tool to a known position, usually the machine's limit switches or fixed physical stops. Once you reach these positions, you can set them as the home position. 3. Configuring the Home Position.

Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools. Generally speaking, there is no need to change or calibrate the reference point after the machine is installed and commissioned, but it is necessary in the following cases: (1) when an axis of the scale or encoder is replaced, the .

Grid shift lets you make small adjustments in the primary (G28) zero return position, but G30 lets you set any point on the machine as a "second" zero point. Grid shift is only good for +/- one full turn of the pulse coder. Almost all current model CNC machine tools have a special reference position. For machines having Fanuc or Fanuc-compatible controls, this special position is called the zero return position. Other names for the machine’s reference position include the home position, grid zero, and machine origin.

When it comes to bonding fabrics to metal, using the right type of glue is crucial for achieving a strong and durable bond. Fabric-to-metal projects often require a specialized adhesive that can effectively adhere to both porous fabric .

cnc machine change reference point|setting a reference point in cnc