sheet metal inspection Virtek LaserQC® dramatically increases throughput in precision sheet metal, tubing, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article . At Matodi, we offer both vertical and horizontal washers that range from entry-level to highly automated (all customizable) to best fit your current and future production needs. Neptun is the leading manufacturer of horizontal and vertical glass washing machines.

0 · surface inspection system for steel

1 · surface finish inspection equipment

2 · sheet metal quality checklist

3 · sheet metal inspection checklist

4 · scanning surface inspection system

5 · inspection lights for surface defects

6 · freescan combo 3d scanner

7 · automated optical surface quality inspection

This table briefly summarizes the levels of protection typically required to seal or vent enclosures that contain electronics. Complete definitions, features and test criteria for all NEMA enclosure types are at www.nema.org.

Visual inspections—The most basic form of inspection, it involves inspectors examining the sheet metal parts for any visible defects, such as scratches, dents, surface irregularities, or inconsistencies in color and finish.

A sheet metal inspection and reverse engineering solution using the InspecVision Planar2D - the worlds fastest 2D measurement system. Manufacturing sheet metal parts can be particularly .Virtek LaserQC® dramatically increases throughput in precision sheet metal, tubing, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article .SmartView Surface Inspection is industry-leading technology for real-time surface defect detection ideal for aluminum, steel, paper, plastics and nonwovens industries.

Sheet Metal Inspection. A sheet metal inspection and reverse engineering solution using the InspecVision Planar2D - the worlds fastest 2D measurement system.Precision Measurement Machines for Smart Manufacturing. We design, manufacture and sell vision systems for automated inspection and reverse engineering. Specialists in Sheet Metal .Our sheet metal inspection ensures precision and quality. Elevate your projects with our comprehensive quality assurance. Get your free quote and learn more! AI and machine learning are revolutionizing sheet metal inspection. Instead of just spotting defects, they’re now predicting and heading off issues before they happen. Using past data, these tools are shifting from just fixing .

Machine learning and AI are revolutionizing sheet metal inspection. Instead of just spotting defects, they’re now predicting and heading off issues before they happen. Using past . Sheet metal inspection is the process of evaluating and verifying the quality, accuracy, and conformity of sheet metal parts to ensure they meet the specified design .A sheet metal inspection and reverse engineering solution using the InspecVision Planar2D - the worlds fastest 2D measurement system. Electrical Laminations Inspection A lamination inspection solution within the Electric Motors, .

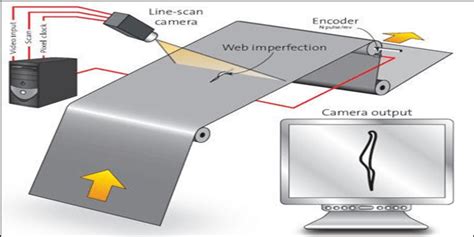

The most advanced surface inspection platform available to the market, SmartView ® combines powerful software, linescan camera technology, high-intensity lighting and industry-leading engineering to deliver a trusted . Sheet metal inspection is crucial for maintaining quality control in manufacturing, preventing defects, and ensuring that the final product meets the necessary standards for safety, performance, and reliability. These metrics help ensure that the fabricated parts meet design specifications and perform as intended. Metal Sheet Thickness Gauge, Stainless Steel Wire Metal Sheet Thickness Gauge Welding Gage Plated Size Double-Sided Inspection Tool Handy and Accurate 4.5 out of 5 stars 47 2 offers from 0 $ 5 70Inspection of Formed Sheet Metal. Micrometers and calipers can still be used to inspect a formed piece of sheet metal, however there are a few tools used specifically for the inspection of sheet metal parts. These tools should be available in any press brake department and sheet metal operators should be trained in their uses.

Precision for Your Sheet Metal Stamping Equipment . Whether you’re punching, blanking, bending, coining, embossing, flanging, cutting or sheering, sheet metal stamping is a precision business. . Improved Inspection and Quality Control . These fast, 3D feature and surface comparisons radically accelerate inspection times and production .

Traditional inspection methods for sheet metal often fall short when dealing with intricate designs and complex geometries. In modern manufacturing, there’s a pressing need for tools that offer both speed and precision. This is where inspection software like Creaform’s VXinspect comes into play.213 Sheet Metal Inspector jobs available on Indeed.com. Apply to Inspector, Quality Control Inspector, Sheet Metal Mechanic and more! Skip to main content. Home. . and monitor each inspection in the housing reporting software and/or mobile tablet to include printing inspection reports for each unit that is inspected and assign rating of pass . Amazon.com: Architectural Sheet Metal Inspection Guide: 9781617210068: SMACNA. Skip to main content.us. Delivering to Lebanon 66952 Update location . An invaluable inspection resource for owners of standing seam, batten seam, or Bermuda-type roofs. Presents practical troubleshooting and corrective tips for typical problems of roof panels .

surface inspection system for steel

Sheet Metal Inspection. Transducer Properties. Center frequencies from 4 to 5 MHz; For plates more than 350 mm; Ultra-high sensitivity; Excellent repeatibility of the acoustical characteristics; Excellent signal-to-noise ratio; Minimal crosstalk; Get in Touch. Ultrasonic Testing of Volume Defects and Thickness Tolerances.FabriVISION maximizes the throughput of your turret and laser by eliminating delays in the inspection process. FVL-HD-3030, FVL-HD-4848, Plus FabriVISION 3Di Laser with 3D intelligence technology . and other rigid parts. If you’re a quality-conscious sheet metal fabricator who strives to stay ahead of your competition, FabriVISION can .

I need some help from my fellow Covers - We are a sheet metal fabricator (job shop). We have a part we make for a customer that is about 18 inches in length. The customer has rejected the part because a dimension to the hole centers is out of tolerance. The cause of this is a slight bow in the material. This is not an uncommon condition in .

The automated solution from ZEISS, ATOS ScanBox, allows a fast and efficient inspection of sheet metal parts. Its non-contact measuring system can be used in the sheet metal forming process to guarantee consistent quality assurance from tool try-out and first article inspection up to production control during series production and assembly analysis.A guide to assist owners and operators with limited knowledge in architectural sheet metal components, fabrication, and installation. This advisory circular (AC) contains methods, techniques, and practices acceptable to the Administrator for the inspection and repair of nonpressurized areas of civil aircraft, only when there are no manufacturer repair or maintenance instructions. This data generally pertains to minor repairs. The repairs identified in this AC may only be used .

A standing seam roof uses a formed sheet metal joint with factory-applied sealant at the side lap joints, and sealant and exposed fasteners at the end lap joints. . However, a more detailed inspection shows that the flashing . This blog post addresses the inspection challenges involved in sheet metal manufacturing. If you are looking to enhance the quality of your sheet metal parts, balance the thoroughness of inspections with cost and time .Sheet Metal Inspection; Electrical Laminations Inspection; Gasket and Seal Inspection; O-Ring Inspection; In Line Inspection; Convert Paper Drawings to CAD; Castings; Reverse Engineering; Quality Control; Rapid Prototyping; Get in touch +44 (0) 2890 844 012 [email protected]. Managed Services.

To schedule a building or sheet metal inspection, please call 617-993-2663 the day before you would like the inspection and leave a message with the following information: Property address, including unit number if applicable; Permit number; Type of inspection; Your phone number; Please speak slowly and clearly and repeat all information. AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code: This specific code addresses the arc and braze welding requirements for nonstructural sheet metal fabrications. It encompasses commonly welded metals available in sheet form and includes requirements and limitations governing procedure, performance qualification, workmanship, and inspection .Whether you need engineering support, sheet metal fabrication, or inspection services, we have you covered. Contact our team to get started. OUR Certifications. ADVANTAGE METAL PRODUCTS. 7855 Southfront Road Livermore, CA 94551 Phone: +1 (925) 455-8789. Email: [email protected] CAREERS. INDUSTRIES.SHEET METAL INSPECTION GUIDE SHEET METAL AND AIR CONDITIONING CONTRACTORS’ NATIONAL ASSOCIATION, INC. www.smacna.org This is a preview of "SMACNA 1937-2004". Click here to purchase the full version from the ANSI store.

Technical standards and manuals developed by SMACNA members have worldwide acceptance by the construction and code community, as well as local and national government agencies. ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and .

surface finish inspection equipment

illustrator distribute evenly wihtin box

Visual Sheet Metal Inspection System; Sheet Metal Inspection; 2D Inspections Systems,Tìm chi tiết về Data Cabinet, Data Center của Visual Sheet Metal Inspection System; Sheet Metal Inspection; 2D Inspections Systems - Jiancheng Electronics Co., Ltd.

Manufacturing sheet metal parts is challenging: inspection remains critical for every sheet metal application. Here Matt Parry, applications engineer at industrial metrology specialist The Sempre Group, and Olivia McNeill, Sales & Marketing Manager at InspecVision, explain why automating inspection is critical. If inspection systems are expensive to purchase . Re: Sheet metal inspection - restrained or unrestrained Yes, but this topic moving off topic has been one of the most interesting topics I've seen in this (the inspection/test) forum in a while. The questions related to the sheet metal were answered two pages ago, but it branched out into an excellent thread on how often stuff is run at .

in custom metal fabrication charge

sheet metal quality checklist

This 30''/36” wide stainless steel under cabinet range hood is a durable companion for your kitchen. Featuring a pair of strong motors, touch screen panel, three baffle filters, and a long LED light, this unit will take your cooking experience to a new level.

sheet metal inspection|automated optical surface quality inspection