steel concrete composite box girder bridges Steel-concrete composite bridges are used as an alternative to concrete bridges because of their ability to adapt their geometry to design constraints and the possibility of . Most ceiling fan boxes require 10 screws. However, some ceiling fan boxes require 8 screws. It is important to use the correct size screws for your ceiling fan box, as .

0 · steel box girder design example

1 · prestressed concrete box girder bridge

2 · prestressed concrete box girder

3 · prestressed box girder bridge

4 · precast segmental box girder

5 · post tensioned concrete box girder

6 · british small box girder bridge

7 · box girder bridge design example

A sheet metal worker is a professional who makes, installs and reconditions sheet metal products, such as various elements that are part of the heating, cooling and ventilation systems, as well as roofing and drainage systems.

To examine the effective width of steel-concrete composite box girder bridges, 120 models were analyzed in simple and double-box configurations. For all models, a cross . In this paper, a beam-truss model is introduced for the design analysis of composite box-girder bridges. An integrated research program for beam-truss models, . Steel-concrete composite girder bridges, in essence, are thin-walled structures, the dynamic responses of which will be greater than those of a typical Euler–Bernoulli beam under the train-bridge interaction because of the . Steel-concrete composite bridges are used as an alternative to concrete bridges because of their ability to adapt their geometry to design constraints and the possibility of .

Composite box girder bridge with rectangular steel box sections. For highway bridges, the structural configuration is usually of a reinforced concrete deck slab, carrying the traffic, on top of steel girders. The deck slab acts compositely with . Among the papers, those that have a method for calculating the effective width of steel-concrete composite girder bridges have been compared quantitatively and qualitatively with the. Curved steel–concrete composite girders are regularly adopted for use in ramp bridges in urban overpasses. As such, it is important that the lateral overturning stability of .This chapter focuses on straight steel–concrete composite box-girder bridges. A single box girder with multiple cells is economical for very long spans. Multiple webs reduce the flange shear lag .

In this study, based on the Euler-Bernoulli beam theory with the finite element method, a steel–concrete composite box girder bridge-train-MR-TMD coupling system .Some alternatives for the design of steel-concrete composite box girder bridges are presented in Figure 1 together with a detail of the steel-concrete interface, highlighting the position of the .Steel box girders and steel and concrete composite box girders are used for long spans, where the self weight of the bridge needs to be minimized, and for situations where their excellent high torsional stiffness is of particular benefit. . Steel–concrete composite bridges consist of steel and concrete parts which are connected by shear connector such as the widely-used headed stud. Through the chemistry bonding, interface friction and mechanical action the two different materials parts are combined as a composite structure system. Because of the structural mechanism, longitudinal and lateral .

The steel-concrete composite box girder bridge is a thin-walled structure composed of different kinds of materials. The unique structure of this bridge type leads to unique mechanical behavior. Specifically, slip between the concrete slab and steel box girder generated by the deformation of shear-connectors and shear-lag which cannot be ignored . A steel–concrete composite beam bridge fully exploits the mechanical advantages of the concrete structure and steel structure, and has the advantages of a fast construction speed and large stiffness. It is of certain research value to explore the application of this bridge type in the field of railway bridges. However, with the rapid development of domestic high-speed .

A 3 × 40 m simply supported steel–concrete composite box-girder bridge is selected to investigate the influence of its time-dependent behavior on its dynamic responses. The results showed that the time-dependent effect will amplify the dynamic characteristics of the composite box-girder bridge and the high-speed train. The maximum vertical . In addition, box girders offer an attractive appearance. The high torsional rigidity of box girders makes this type of construction preferable for bridges with curved girders. Also, the high rigidity assists the deck in distributing loads transversely. This is illustrated in Fig. 12.50. A single load placed off center on a bridge with single .composite box-girder bridges, especially curved bridges owing to their high torsional stiffness, certain design guidelines have been summarized and suggested as a result of numerical analysis using There are few studies on the temperature actions of steel-concrete composite structure bridges, especially in comparison to traditional bridges. For railway steel-concrete composite girder, temperature-induced deformations pose a more significant risk compared to highways, especially with the passage of high-speed trains. Yang et al. [27 .

The Steel Construction Institute Silwood Park Ascot Berkshire SL5 7QN Tel: 01344 623345 Fax: 01344 622944 . P:\CMP\Cmp657\pubs\P140\P140V02.doc ii Printed 16/02/04 . For medium span highway bridges, composite box girders offer an attractive form of construction. Design and construction techniques already popular and Steel-concrete composite bridges are used as an alternative to concrete bridges because of their ability to adapt their geometry to design constraints and the possibility of reusing some of the . Steel-concrete composite bridges fully utilize the mechanical properties of the materials. These bridges have lower self-weight and better seismic performance than concrete girders, and they avoid the fatigue cracking problem encountered in the orthotropic plates of steel girders, thereby making them widely used in railroad engineering with broad application .

The results show that compared with the ordinary concrete beam bridge, the steel-concrete composite simply supported box girder bridge has a 70% reduction in web weight, and has a stronger . The behaviour of a continuous, steel-concrete composite box girder bridge was monitored during construction of the concrete deck and during the first three years of operation. It was observed that . The utilization of steel-concrete composite girders in the civil engineering offers several advantages, such as a favorable strength-to-weight ratio, improved structural efficiency, decreased deflections, increased durability, simplified construction, expedited project schedules, adaptable and gradual construction, structural redundancy and safety, and aesthetic flexibility .

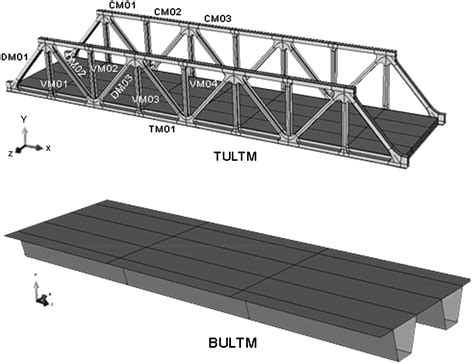

Based on the vehicle flow information of the highway within 10 years, the fatigue performance of a two-way four-lane steel-concrete composite continuous beam bridge deck is studied in this research.Composite steel box girder bridges have become an effective alternative to more conventional plate girder bridges and concrete girder bridges in North America in the past 25 years. At present a number of innovations taking place in Ontario and elsewhere have the potential of further enhancing the design, durability, .Based on the vehicle flow information of the highway within 10 years, the fatigue performance of a two-way fourlane steel-concrete composite continuous beam bridge deck is studied in this research. .e results indicate that the effect of the wheel track position is negligible for two-way four-lane bridge when the wheel track sways laterally, and . In this paper, a beam-truss model is introduced for the design analysis of composite box-girder bridges. An integrated research program for beam-truss models, including modeling implementation .

rapid sheet metal inc

The present paper aims to determine numerically in the Abaqus ® software the parameters that have the greatest influence on the effective width of steel-concrete composite box girder bridges. In the technical standards and in the literature, there is no specific recommendation for calculating the effective width in steel-concrete composite box girder bridge. The bridge is a three-span steel composite I-girder bridge with a total length of 206.5m. The main span is 73.5m long and the side spans are 66.5m long. This bridge is supported by abutments at both ends and two large piers with 8 piles each between spans. In the case of steel-concrete composite bridges, a widely adopted solution is the use of box girders, 43 which presents a series of advantages, such as greater torsional rigidity, durability .

Bridge optimization can be complex because of the large number of variables involved in the problem. In this paper, two box-girder steel–concrete composite bridge single objective optimizations have been carried out considering cost and CO $$_{2}$$ 2 emissions as objective functions. Taking CO $$_{2}$$ 2 emissions as an objective function allows to add . 1. Introduction. A steel-concrete composite box girder bridge is directly exposed to the environment, and the energy exchange between the bridge and the surrounding environment affects the temperature field of the composite box girder bridge [1 – 5].For bridges with steel box girders, temperature changes impact the stress and deformation of the main girder, resulting in .

This paper presents the structural performance of steel-concrete composite decks with profiled steel sheeting. The main objective of this study is to develop a longspan composite deck that weighs, less than the conventional cast-in-place concrete deck. The proposed deck system is composed of profiled sheeting that is perpendicular to the steel girder with perfobond rib shear . 1. Introduction. Horizontally curved steel–concrete composite box girders are widely used in construction of highway bridges. This type of structural system consists of a concrete deck connected with a steel box section beam that exhibits a high torsional rigidity which is important in resisting torsional effects produced by the curvature of the structure. To study the effect of the temperature field and gradient of a steel-concrete composite box girder bridge, a 5 × 35 continuous composite box girder bridge is used as the research object.

steel box girder design example

prestressed concrete box girder bridge

prestressed concrete box girder

What type and size of screws are need for each type of connection box? Generally the screw you need should come with the cover. Typically cover screws are 6/32. Do your faceplates not come with screws? Most hardware stores I have been to had a specific electrical screw section in their fastener area.

steel concrete composite box girder bridges|precast segmental box girder