swaging operation in sheet metal Swaging is a fundamental metalworking process that utilizes compressive forces to shape and deform metal parts or components. This technique involves the use of . Dive into our online wholesale cnc machined parts products catalog on globalsources.com! Source over 17411 cnc machined parts for sale from manufacturers with factory direct prices, high quality & fast shipping.Source over 158 power distribution boxes for sale from manufacturers with factory direct prices, high quality & fast shipping.

0 · what is the swaging process

1 · what is a swagging machine

2 · what is a swage

3 · swaging machine process

Find complete sets of walk-in cooler panels to create a walk-in cooler box for your cold storage. Shop staurantStore for fast shipping & wholesale pricing!

1. A Beginner’s Guide to Swaging Machines: Perfecting Sheet Metal Shaping and Forming. In the realm of metalworking, where precision and artistry intertwine, the swaging machine emerges as an indispensable tool for shaping and forming sheet metal. For those .Swaging machines optimize material utilization by minimizing waste and .As a noun, swaging can transform a piece of metal into a desired shape through pressure or hammering. Swaging results in taking an object and giving it a . Swaging is a fundamental metalworking process that utilizes compressive forces to shape and deform metal parts or components. This technique involves the use of .

Swaging machines optimize material utilization by minimizing waste and ensuring efficient use of sheet metal. The machines’ precision control allows for precise forming without the need for .

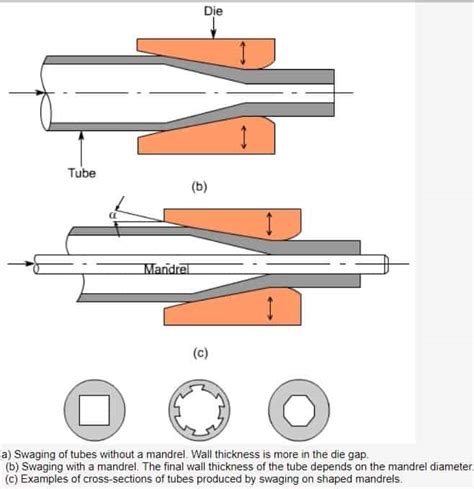

At its core, swaging is a metal forming method that is used to reduce rod, wire or tube. Unlike other methods, swaging uses a rapid succession of hammer strikes to form the metal. This chipless metal forming method, is an . Tube swaging is a process of forming metals that is used to cut down or alter the diameter or shape of rods or tubes. This process is unique because it does not require welding or cutting. In this guide, we will explore all .

curving sheet metal by hand

Swaging, also pronounced “swedge”, is a metal-forming technique in which the metal of one part is deformed to fit around another part by either pressing or hammering, or by forcing the material through a die. Swaging differs from .

Swaging is the deformation of fixing portions of workpieces in order to permanently fix parts to each other. There are 2 types of fixing that utilize swaging: fixing parts to each other and fixing parts to each other such that .Metal swaging or radial forging involves the forging of a work piece by use of die that exert compressive forces by impacts that act around the work's circumference. In manufacturing industry, swaging is usually performed as a . Metal swaging, pronounced ‘swedging’, is a technique for cold forming metal to the shape of a pre-made die. The process sees the metal deformed through the application of steady force, with the end shape of the .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .

Buy Rm-08 7'' Sheet Metal Bead Roller Rotary Burring Swaging Machine Rotary Steel Bending Bender Manual Tool Low Carbon Professional Sheet 22 Gauge 6 Die Sets Tool: . 【Manual Operation】Sheet metal bead roller calls for manpower operation. Working speed is all at your control. Pausing at any time is supported. Metal Bead Roller 7'' Sheet Rotary Burring Swaging Machine Rotary Steel Bending Bender Manual Tool Low Carbon Professional Sheet 22 Gauge 6 Die Sets Tool . 【Manual Operation】Sheet metal bead roller calls for manpower operation. . trunk pans and firewalls. Ideal for sheet metal fabrication shops and automotive industry for Performs .From workshop to construction site, Press and Shear’s range of ducting and swaging machines offers users a large choice of machines to suit most forming, ducting and seaming applications. . You can part exchange your sheet metal and fabrication machinery. You’ll receive a competitive price for your existing machine which can be offset .Today we will learn about swaging process. Swaging is a metal forming process of reducing diameter of a rod or tube by forcing it into a die with the help of reciprocating blow. This will plastically deform the metal and force it to flow into die and acquire die cavity shape. . Different Sheet Metal Operations . 2 thoughts on “Swaging .

It can also size, reduce, shape, taper, bond, or form metal parts. Benefits of Swaging Machines. Swaging offers numerous benefits to companies who choose this method of metal forming. High finish – Because the end result includes a high finish, this can eliminate the need for secondary operations, saving both time and money. 【Manual Operation】- Sheet metal bead roller calls for manpower operation. Working speed is all at your control. . 7 Inch Sheet Metal Bead Roller Rotary Burring Swaging Machine Rotary Steel Bending Bender Manual Tool, Forming Bead Roller Steel Bende Low Carbon Professional Sheet 22 Gauge 6 Die Sets Tool. Share:

The operation of sheet metal rolling machines is not without its challenges. Safety protocols must be strictly adhered to, as the powerful rollers can pose a hazard if not handled with care. Proper workpiece preparation and lubrication are essential to prevent damage and ensure smooth bending. . Top Benefits of Using a Swaging Machine in . Drawing: Stretching a sheet over a form, causing it to conform to a curved or angular shape. Rolling: Passing a sheet between rollers to reduce its thickness or to create a rounded shape. Types of Machines: Tailored to Specific Needs. The diverse range of sheet metal forming machines available cater to different manufacturing requirements.IThe RAS 11.15 with manual drive is the ideal swaging machine for the workshop as well as the construction site. The standard delivery already includes 9 sets of wheels for all common applications. Swaging Machine RAS 11.35: Motor Drive. The RAS 11.35 swaging machine comes on a stand and with 9 sets of wheels for all common applications. Sheet Metal Forming Operations. Fig 2: Forming Operations. Bending. Bending is a fundamental operation in sheet metal forming. In this process, a flat sheet or strip of material is subjected to external forces that cause it to deform and take on a specific angle or curvature around a linear axis.

Mechanical Advantage Tube Expander HVAC Swaging Tool Kit with Tube Cutter, Deburring Tool & 11 Expander Heads 3/8 to 1-5/8 Inches for Copper & Aluminum Refrigeration Pipes Expander Tools . Manual Operation. Sheet metal bead roller calls for manpower operation. Working speed is all at your control. Pausing at any time is supported. Much more .(e) squeezing, (d) swaging, or (e) turning? (a) ( (b) (c) (d) (e) 1. A sheet metal cutting operation that cuts out a portion of metal from the interior of a sheet or strip that will become part of the outline of the blank is called which one of the following: (a) cutoff, (b) notching, (c) parting, (d) seminotching, or (e) slotting? Top Benefits of Using a Swaging Machine in Sheet Metal Processing. By:Metmac; 2024-11-14; 22; Introduction: .

custom architectural metal fabrication services

Workers utilize power presses for heavy industrial situations where high pressure is needed to press, cut, form, or bend sheet metal. The sheet metal can be of various sizes and shapes, and the power press will still work. This machine is incredibly adaptable and has made the job of sheet metal workers easier. Bending Machine. This tool is .

BENCH SWAGER SWAGING MACHINE (BEAD ROLLER) BENCH SWAGER HEAVY DUTY PROFESSIONAL TOOL 7″ THROAT. Part Numbers:0208. COMPLETE WITH 6 SETS OF MANDRELS. CAN WORK IN FORWARD AND .

Typical press operations are defined below: . Drawing-A process in which a shell of any shape, is produced from flat sheet metal. Holding pressure is applied to the blank edge to prevent wrinkles in the flange as the punch forces the metal . Swaging is primarily used as a metal forming method to reduce rods, wires, and tubes. It’s a highly economical method for remodeling existing products with minimal waste. . Both processes also fall under cold metal forming operation in contrast to hot forming processes such as hot rolling, welding, and forging. The fundamental difference .Swaging machines are pivotal tools in the sheet metal fabrication industry, offering a myriad of advantages in terms of efficiency and precision. These versatile machines have revolutionized the way sheet metal components are formed and shaped, resulting in significant improvements in product quality, production speed, and cost-effectiveness.

custom aluminum fabrication toronto

Both blanking and piercing are shearing operations. In case of piercing or punching, the material which is cut out from the sheet metal is scrap and the reining material is the actual part. Difference between Blanking and Piercing. As I said earlier, both are metal shearing operations used for cutting sheet metal. The major differences are as . Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting. Buy 1Pcs Steel Swaging Punch Hand Tool Tubing Pipe Expander Metal Processing Tool for Industry (CT-95): . Operation Mode: Manual: Sheet Count: 1: About this item . High quality material: This tubing pipe expander metal processing tool is made of high quality steel, it is sturdy and reliable to use. A great choice for you ;

There’s no denying that sheet metal plays a pivotal role in projects across numerous industries. Sheet metal is commonly fashioned from steel or aluminum and typically takes a thin and flat form. Despite this, sheet metal alterations are commonplace — and essential — depending on the application in question. This is where the forming of sheet metal parts .

Shave operations most commonly associate with punched openings such as round holes, but free-edge features also can be shaved. . The die-matrix opening should measure 1.25 to 1.50 percent of sheet metal thickness per side larger than the shave punch: 0.032 in. x 1.5 percent = 0.0005-in./side. Thus, the final matrix diameter measures 0.3762 in.Besides, manual and semi-automatic operations are available. KDM is your leading supplier. Send Inquiry. Metal Pipe Embossing Machine for Decorative Sheet . Metal Pipe Embossing Machine for Decorative Sheet can process stainless steel pipe, iron pipe, pipe, aluminum pipe. Besides KDM can custom different types of machines based on the client . The various operations performed in a sheet metal shop are marking cutting, shearing, bending & joining etc. . False wiring SWAGING Making a groove in sheet metal in round job by swaging machine is called swaging. BENDING It is same as swaging but done away from the edge, it is done by bending machine giving concave shape on the sheet.Sheet Metal Machines; Swaging Machines. Swaging Machine Manufacturer in India ! This machine is designed for various operations with semi-automatic system. Since Master exports inception in 1962, we have gained experience and expertise of many years in this industry. Our network of manufacturers, dealers, and clients spans access national as .

what is the swaging process

Fast, accurate machining of parts means highly efficient production rates, which also contributes to quicker assembly processes. Even manual assembly lines are made more efficient by using CNC machining to produce parts that fit seamlessly together.

swaging operation in sheet metal|what is a swage