cnc g0704 part 2 2 nema 23 motors for X & Y 570 oz/in 5A 1/4" Dual Shaft Stepper Motors. Control software is Mach4 software. It can be viewed HERE. The software comes with a Dell touch screen Laptop . When it comes to sheet metal welding, the type of metal you use can make all the difference. The choice of metal for sheet metal welding depends on the project’s specific requirements, such as strength, corrosion resistance, and aesthetic considerations.

0 · grizzly model g0704

1 · grizzly g0704 upgrades

2 · grizzly g0704 manual

3 · grizzly g0704 cnc kit

4 · grizzly g0704 cnc conversion kit

5 · grizzly g0704 benchtop mill

6 · g0704 cnc conversion plans

7 · g0704 cnc conversion kit

Choosing the right size screws for electrical boxes is crucial for a secure and stable installation, ensuring safety and preventing hazards such as loose connections or compromised structural integrity.

I'm using a PC case, as it was inexpensive and has plenty of room to add extra components such as spindle control boards etc at a later date.I'm following th.

G0704 CNC conversion part 2. Disassembly, milling pockets for Y axis extension and ball screw, along with oil channels.Music by Fedor Baranov of Impervious..Pls see the following video: CNC G0704 Part 2 - Assembling the Control Box. CNC G0704 Part 3 - Teardown. CNC G0704 Part 4 - Y Axis Installation. CNC G0704 Part 5 - X Axis Installation. CNC G0704 Part 6 - Z Axis & Done.

Part 2 of the chip guard build Here is the epoxy I use http://amzn.to/2bYJ9do Thanks for stopping by folks, my videos are designed mostly for newer machinists and fabricators looking to check.

2 nema 23 motors for X & Y 570 oz/in 5A 1/4" Dual Shaft Stepper Motors. Control software is Mach4 software. It can be viewed HERE. The software comes with a Dell touch screen Laptop . In Ryan’s G0704 post he scraped the ways, resulting in a much more accurate surface as well as eliminating the looseness issues. However, I am going to eliminate the dovetail ways entirely and instead replace them with .I'm using a PC case, as it was inexpensive and has plenty of room to add extra components such as spindle control boards etc at a later date.I'm following th.

G0704 CNC conversion part 2. Disassembly, milling pockets for Y axis extension and ball screw, along with oil channels.Music by Fedor Baranov of Impervious..Pls see the following video: CNC G0704 Part 2 - Assembling the Control Box. CNC G0704 Part 3 - Teardown. CNC G0704 Part 4 - Y Axis Installation. CNC G0704 Part 5 - X Axis Installation. CNC G0704 Part 6 - Z Axis & Done. Part 2 of the chip guard build Here is the epoxy I use http://amzn.to/2bYJ9do Thanks for stopping by folks, my videos are designed mostly for newer machinists and fabricators looking to check.

2 nema 23 motors for X & Y 570 oz/in 5A 1/4" Dual Shaft Stepper Motors. Control software is Mach4 software. It can be viewed HERE. The software comes with a Dell touch screen Laptop with everything set up. All aluminum parts anodized to be scratch and corrosion resistant. All stainless steel hardware. It also includes the stand. In Ryan’s G0704 post he scraped the ways, resulting in a much more accurate surface as well as eliminating the looseness issues. However, I am going to eliminate the dovetail ways entirely and instead replace them with linear guide rails from Misumi. Shop-built 4 axis CNC Sherline mill with A2ZCNC extended XY and CNC Sherline lathe. 4 axis CNC Grizzly G0704 - based on Hoss' plans Manual Sherline 4400 and LMS 3540 lathes Well, since you guys did not let me buy an inexpensive metal lathe to play with (link to that thread). decided to convert my G0704 to a CNC machine. Will document my journey with this project here. A few threads and videos I looked at on this.

I am fairly luck that the Dallas chapter has a well tooled machined shop area for me to be able to complete my project. The big stuff they have is a Bridgport Mill with DRO, 2 larger lathes, and even an older Haas CNC ( wish i had training to . It is designed to fit a Nema23 stepper motor. The 4 outer holes are to mount the stepper standoffs and the 3 around the bearing pocket are to secure the bracket to the base. The lower hole on the base will need to be drilled and tapped as it does not exist (or left out entirely).

grizzly model g0704

I'm using a PC case, as it was inexpensive and has plenty of room to add extra components such as spindle control boards etc at a later date.I'm following th.G0704 CNC conversion part 2. Disassembly, milling pockets for Y axis extension and ball screw, along with oil channels.Music by Fedor Baranov of Impervious..Pls see the following video: CNC G0704 Part 2 - Assembling the Control Box. CNC G0704 Part 3 - Teardown. CNC G0704 Part 4 - Y Axis Installation. CNC G0704 Part 5 - X Axis Installation. CNC G0704 Part 6 - Z Axis & Done. Part 2 of the chip guard build Here is the epoxy I use http://amzn.to/2bYJ9do Thanks for stopping by folks, my videos are designed mostly for newer machinists and fabricators looking to check.

p.i.t. portable 3 drawer steel tool box

2 nema 23 motors for X & Y 570 oz/in 5A 1/4" Dual Shaft Stepper Motors. Control software is Mach4 software. It can be viewed HERE. The software comes with a Dell touch screen Laptop with everything set up. All aluminum parts anodized to be scratch and corrosion resistant. All stainless steel hardware. It also includes the stand. In Ryan’s G0704 post he scraped the ways, resulting in a much more accurate surface as well as eliminating the looseness issues. However, I am going to eliminate the dovetail ways entirely and instead replace them with linear guide rails from Misumi.

Shop-built 4 axis CNC Sherline mill with A2ZCNC extended XY and CNC Sherline lathe. 4 axis CNC Grizzly G0704 - based on Hoss' plans Manual Sherline 4400 and LMS 3540 lathes

painted aluminum sheet metal suppliers

grizzly g0704 upgrades

Well, since you guys did not let me buy an inexpensive metal lathe to play with (link to that thread). decided to convert my G0704 to a CNC machine. Will document my journey with this project here. A few threads and videos I looked at on this. I am fairly luck that the Dallas chapter has a well tooled machined shop area for me to be able to complete my project. The big stuff they have is a Bridgport Mill with DRO, 2 larger lathes, and even an older Haas CNC ( wish i had training to .

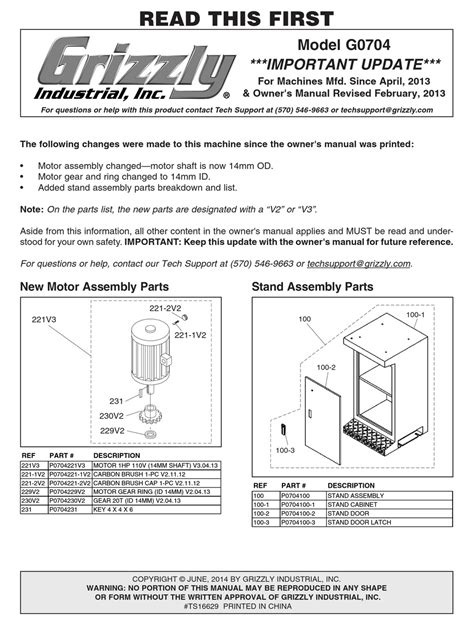

grizzly g0704 manual

It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To weld mild steel, choose an American Welding Society classification wire such as ER70S-6, which has a weld puddle that wets out nicely.

cnc g0704 part 2|grizzly g0704 upgrades