k factor table for sheet metal What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses. 【Large Size】The largest single-sheet magnet available on the market, our magnetic sheet measures 12 inches by 8.5 inches. Easily stick large posters or 14-inch photos onto your fridge or other metallic surfaces. 【Extra Strong Magnetic Backing】The 20mil (0.5mm) thickness ensures an extra strong magnet, suitable for even heavier items.

0 · solidworks sheet metal k factor

1 · k factor sheet metal calculator

2 · k factor explained

3 · k factor bending sheet metal

4 · bending calculation for sheet metal

5 · bending allowance in sheet metal

6 · bend allowance k factor chart

7 · 304 stainless steel k factor

See more at: http://www.goengineer.com/products/solidworks/Learn how to get started with SOLIDWORKS Sheet Metal. Whether you have just started using SOLIDWOR.

This K-factor calculator will assist you in finding the K-factor for sheet metal. Sheet metal is the building block of structures, from forming the body of automobiles to the skin of aircraft wings.

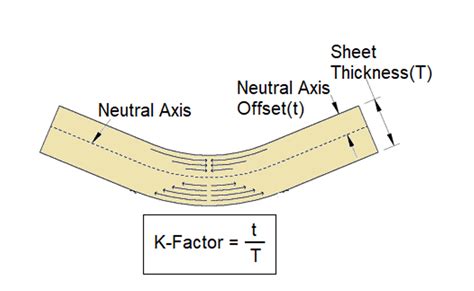

The K-Factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. It’s used to determine Bend Allowances and Bend Deductions ahead of the first piece. The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending .Calculate. K Factor: Bend Allowance: mm. Y Factor: Calculate the K-factor for your sheet metal with our user-friendly online calculator. Ideal for engineers and designers. What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses.

Article. Bending and Forming. Figure 1. When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. The K-factor is the ratio of the neutral axis location (t) to the material thickness (Mt). Question: . The k-factor allows you to calculate the bend allowance, the outside setback, the bend deduction, and the flat layout of the precision part you’re forming. Defining the Neutral Axis. To understand the k-factor, you .

solidworks sheet metal k factor

The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and .To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left. After bending the sheet, . mike miller wrote: ↑ Mon May 17, 2021 8:23 pm @DennisD yes, we actually used your method to determine the K-factor for each material thickness we use. My biggest question now is how to implement this. For example, the gauge table will specify a K-factor across the board, but obviously that won't agree with a bend table.

Hi all, I was wondering if there was any way to expand the imperial gauge table for sheet metal, as I am using gauges other than the 3 through 5 that they provide. I know that I can edit the spreadsheet myself, however, the cells do .K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × . The k-factor is fundamental to designing precise sheet metal products. It allows you to anticipate the bend deduction for a large variety of angles without having to rely on a chart. While modern bend deduction charts now are reasonably accurate, historically bend calculation charts, both for bend allowances and bend deductions, were notorious .

What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.

Start a new part > create a base flange > set the sheet metal parameters to whatever you want > delete the base flange feature and any sketches > save as part template > enjoy your new defaults Extra tip: K factor is a dimension that can be used in custom properties. The syntax is "D2@[email protected]". I have my templates set so .K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format. The K-factor is determined by the physical properties of the material, bending method, bending angle, and other factors. Material Properties: it typically ranges between 0.30 and 0.50.In general, the K-factor of soft copper or soft copper materials is 0.35, the K-factor of materials such as semi-hard copper or brass, mild steel and aluminium is 0.41, and the K .

160 SolidWorks Sheet Metal Tutorial: K-Factor, bend allowance, calculating K-factor manually/by table/ software The SolidWorks Sheet Metal tutorials section . The bend allowance/bend deduction of the sheet metal (specified in K-factor) By configuring and utilizing a sheet metal gauge table, we can speed up the process of selecting the correct wall thickness (based on gauge value) and selecting the correct bend radius (based on available tooling).We can also automate the process of selecting the .

K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the material thickness where neither compression nor tension occurs during bending. Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal parts that were bent using the following formula: As discussed previously, there are several sources from which the K-factor value can be obtained, such as material suppliers, test data, experience, and manuals. To establish an accurate sheet metal model using the K-factor . In reality, how a real metal part will stretch as it bends depends on a number of physical factors (tooling, material homogeneity etc.) which can’t be accurately replicated using a ‘fudge’ K-factor. Most sheet metal shops will produce their own bend tables by physically bending test pieces to specified angles and taking accurate .

The K factor is a key metric in many fields like statistics, engineering, and manufacturing. This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical .

I work on Solidworks Sheet Metal for designing sheet metal boxes, plates, hoppers,etc. But when it comes to entering K Factor for Mild Steel and Stainless Steel it gets confusing as this affects the blank size. In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data. With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the .

I’d like to review K-Factor and how K-Factor applies to your sheet metal designs. K-Factor Defined. K-Factor– A constant determined by dividing the thickness of the sheet by the location of the neutral axis, which is the part of sheet metal that does not change length. So if the thickness of the sheet was a distance of T = 1 mm and the .For each sheet metal part, you can either specify a K-factor or use the default one. Changing the K-factor for a Sheet Metal Part. To change the K-Factor for a sheet metal part, select the root node in the Mechanical Browser and type a value in the K-Factor field. The value must lie in the range [0, 1], since the neutral surface is located .

You can specify the bend allowance or bend deduction values for a sheet metal part in a bend table. You can also specify K-Factor values in their own K-Factor bend tables. The bend table also contains values for bend radius, bend angle, and part thickness. . or k-factor values in the spreadsheet, depending on your choice for Type in step 2 .

CATIA V5 is the metal bending software of choice across many industries. This tutorial covers how the K-Factor impacts metal bending and Learn how to calculate the K-factor in Sheet Metal Bending with this CATIA V5 tutorial.

The neutral axis is a theoretical place within the sheet metal material thickness that experiences no expansion or . So, what is the “best” way to recalculate your k-factor tables? Perhaps it’s an Excel spreadsheet. Perhaps you can bend test pieces. Just know that the k-factor is but one variable among many to consider. Slide Show | 5 . In SolidWorks, go to "system options", "file locations", then using the dropdown menu select "sheet metal gauge table". This is where you will copy the gauge tables to, or you can add a path to anywhere that you would like to store the gauge tables. . Using these values, you will then need to change the (k-factor) until you get the bend .K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.Overriding Default Gauge Table Values. You can use the sheet metal gauge table to assign values for the whole part. This is called the default. However, you can modify K-Factor, bend allowance, and bend deduction per feature or per bend. You can do this in the PropertyManager by selecting Custom Bend Allowance and making selections.

k factor sheet metal calculator

5001-96-SS-10 Long Solid Handle Bar Pulls, 10 Pack, 3.75" x 6.125", Stainless Steel

k factor table for sheet metal|bending calculation for sheet metal