cnc machining flatness How can one get a flatness under .0003" for a 28" x 10" plate of 1018 steel?-I can use 1/2", 3/4" or 1" thickness.-The whole thing doesn't necessarily have to be flat; but I am mounting support blocks to it in several places, and the mounting surfaces need to be dead flat, *and* all sit at the same height within .0003". The new dishwasher is a Bosch, which has its own electrical box that needs to be mounted in a cabinet next to the dishwasher (usually the under-sink cabinet). The existing .

0 · geometric tolerance cnc

1 · flatness of cnc machined parts

2 · flatness in cnc machine

3 · cnc tolerances explained

4 · cnc tolerance range

5 · cnc machining tolerances

6 · cnc machine flatness chart

7 · 3 axis cnc machine

The LOCATOR Male pivots in its permanent metal denture housing for a genuine resilient connection of the prosthesis. The retentive nylon male remains in static contact with the female socket while its metal denture cap has a full range of rotational movement over the male.

+1 on the manual machining. I always liked the fact that I could feel ( and hear ) the cut. I am at this moment doing some consulting at a shop that is building 2 machines that I designed years ago. 2 guys are cnc only. 1 of them is a lathe guy an he is pretty good at it. The other one is a mill guy and not so good. We check flatness coming out of op 2 even though we know they won't be good parts as far as flatness is concerned. This is done to make sure they don't go past about .006" out of flat, since anything more than that, op 3 won't clean up. We generally will get about 300-600 parts from one corner of the inserts at 375 SFM before they go past .006".

At times, some of these parts will have reasonably tight tolerances for parallelism and/or flatness, for example +/- .002 on dimension, or .0008 total parallelism. I'll admit - I am rather inexperienced with CNC milling. I've had to take on the role of programmer due to our previous man leaving, and I really want to try to solve this problem. This part includes general geometrical tolerances of straightness and flatness. It also includes circularity and cylindricity. ISO 2768-2 simplifies draws, fixing general tolerances in three classes — H, K, and L. . From AT-Machining, I’m a CNC Machining Expert in this field for more than 20 years. We offer cost-effective machining . How can one get a flatness under .0003" for a 28" x 10" plate of 1018 steel?-I can use 1/2", 3/4" or 1" thickness.-The whole thing doesn't necessarily have to be flat; but I am mounting support blocks to it in several places, and the mounting surfaces need to be dead flat, *and* all sit at the same height within .0003".Tolerancing Guidelines for CNC Machining. Also, be aware that these are bilateral tolerances. If expressed in unilateral terms, the standard tolerance would read +0.000/- 0.010 in. (or +0.010/- 0.000 in.) while a limit-based tolerance in our bracket example would be 1.005 / 0.995 in.. All are acceptable, as are metric values, provided that you spell them out on the design.

geometric tolerance cnc

When it comes to precision CNC machining where every detail and dimensional tolerance are crucial, two important concepts play a significant role: straightness and flatness. Straightness and flatness help define the shape and form of a feature on a part, and understanding each one is essential for achieving meticulous accuracy. Guys looking to machine 1.25x18x27inch plate as flat and parallel as possible in either 6061 or 7075 skimming off as little as necessary to get it right. I could possibly go up to a 1.5" thick plate. How flat is realistic? Would .001" flatness along the whole plate even be possible? Machine is a fairly low hours Haas. Is there a way to check flatness with a renishaw probe in a haas to see if a part is loaded correctly? . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new .

CNC Machining Services. CNC Turning. CNC Milling. sheet metal fabrication. 3D Printing. Cooperative supply services. EDM Machining. Investment Casting. Aluminum Extrusion. . Common tolerances for flatness in machining and manufacturing processes can vary widely depending on the material, the size of the surface, the type of process used, and . We test flatness on aerospace stuff with granite and an electronic height gage. Our typical callout is .002 or .005 flatness. that is easily detectible with our Tesa Hite. Only other ways I know of to inspect flatness is optical or CMM. Remember too that flatness is different than parallelism and is sometimes misinterpreted. Tips on Holding Flatness. Thread starter rokstarr999; Start date Jul 8, 2024; Replies 14 Views 574 R. rokstarr999 Aluminum. Joined Feb 7, 2014 Location Sonoma County, USA. Jul 8, 2024 #1 8.5" dia x .609 total thickness down to .045" +.002/-.002 lip inside the large cutouts. . CNC Machining. ABOUT PRACTICAL MACHINIST. This table specifies the permissible deviations for straightness and flatness based on the nominal lengths in millimeters. These tolerances ensure that surfaces are even and straight to a specified degree, critical in maintaining structural integrity and function. . On-demand CNC Machining prototyping and parts with Custom Finishes and low .

On one of our special purpose machines, we could get .0002" flatness or better. I would expect something more in line with .000050" flat and parallel for only 24". On a CNC milling machine in decent condition, .0006-.0003 is a better estimate. I would not try this on a manual mill, as most don't have anywhere near the requisite accuracy.I have a part (approx 150 x 120mm) that needs excellent flatness, but it must be by CNC milling. It would be too costly in production to use a secondary process (e.g. lapping) Hope someone can help me. . If strength is not an issue one can machine the surface close to that required then stresses relieve the material and finish the machining . CNC Machining . Flatness. Thread starter rickk; Start date Oct 16, 2011; Replies 11 Views 6,885 . 9 million a year we are using mori seiki nl 2000 to machine these parts are only problem is we have to hold a 10 micron flatness and a 1 RA surface finish in powdered metal i know fun stuff. we are holding are own but the ones we do get for high .

I need to mill a thick 200mm * 200mm Aluminum 6061-T6 plate with a flatness requirement of 0.02mm and best surface finish that can be obtained by milling. What is the best tool for these requirements? Face mill or end mill? . Are you using a manual machine or cnc? Manual machine, like a bridgeport, is easy to check the tram of head. . I was able to get my flatness down to .0003 by placing the part on a newly faced fixture plate. Thankfully there is a bolt circle on the lower step around the island, so I can hold the part while leaving the top face open to be cut. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year .

Every week, Team Protocase is bringing you a Proto Tech Tip video, where we'll give an informative look at a particular aspect of sheet metal fabrication and.

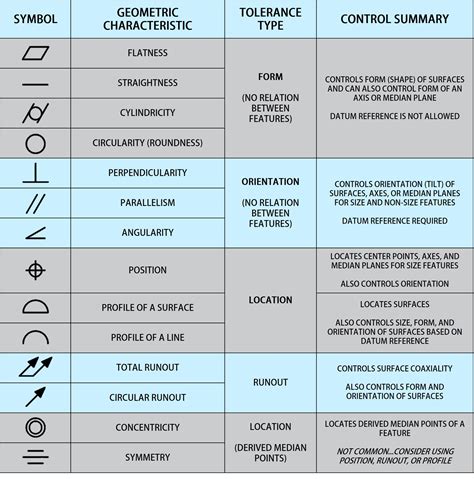

Standard CNC machining tolerances depend on their linear measurements: Fine (f) ranges from ±0.0019685 to ±0.019685 inch (±0.05 to ±0.5 mm) . flatness, and positioning. GD&T uses extremely precise measurements for a part’s dimensions. GD&T looks at the following when considering CNC machining tolerances: CNC Machining . Flatness issues milling 304 stainless. Thread . . Flatness issues milling 304 stainless. Thread starter Ukraine Train; Start date Feb 17, 2016; Replies 21 Views 11,118 Prev. 1; 2; First Prev 2 of 2 Go to page. Go. Atomkinder Titanium. Joined May 8, 2012 Location Mid-Iowa, USA. Mar 29, 2016 #21 It's probably been said enough by . Flatness is an important concept in GD&T used for controlling flat surfaces. Read on how the flatness callout is used in your engineering drawings. . Whether custom CNC machining, 3D printing, or rapid injection molding, WayKen’s commitment to GD&T guarantees that every component meets the strict standards of precision and functionality.

CNC Machining . 303 Stainless-- Help with order of operations / flatness. Thread starter rokstarr999; Start date Jan 10, 2023; Replies 13 Views 1,419 R . flatness-wise. Reactions: Don Davis 87 and rokstarr999. mhajicek Diamond. Joined May 11, 2017 Location Maple Grove, MN, USA. Jan 10, 2023 CNC machining is a precise and controlled process that can be used to achieve very tight tolerances and flatness requirements. In conclusion, post-casting machining is an important process in .Quality Assurance in CNC Machining. Flatness serves as a key indicator of quality in CNC turning machining. Rigorous quality assurance measures, including continuous monitoring and inspection during CNC processes, ensure that surfaces maintain the specified flatness. This meticulous attention to detail guarantees the precision and reliability . CNC machining tolerances are important parameters when manufacturing products, no matter their intended applications. Nowadays, most industrial and consumer products require consistency to meet manufacturing standards. . Similarly, it indicates the part’s geometric properties, including its flatness, concentricity, and true position. More .

Welcome to Intellicut Inc, We Offer Unsurpassed Level Of Precision CNC Machining with unparalleled customer service That Meets Your Mission-Critical Needs. ISO9001:2015, AS9100:2016 certified, NIST SP-800-171 certified, ITAR registered.

flatness of cnc machined parts

flatness in cnc machine

cnc tolerances explained

electrical box on my property

What is a Septic Distribution Box and How Does it Work? A septic tank distribution box, or D-box, is a junction box that connects the outlet pipe from the septic tank to the multiple distribution pipes heading to different sections of the drain field.

cnc machining flatness|cnc machine flatness chart