fiberglass duct board vs sheet metal Sheet metal looks professional, takes longer and results in more leakage but duct board is quick, doesn't leak and doesn't sweat. Just wanting to know what the industry norm is . My brake light was stuck on and still is. I replaced the bulb and no difference. I removed the front cover under the high beam headlight and saw the connector with the orange/ two red wires (one with white strip) connected to the brake pressure switch.

0 · insulated fiberboard for duct work

1 · hvac duct board sheets lowe's

2 · hvac aluminum vs galvanized ducting

3 · galvanized vs aluminum ductwork

4 · flexible ductwork vs rigid

5 · flex duct vs sheet metal

6 · duct replacement with board

7 · alternatives to sheet metal

It means you withdrew or spent $200 from your HSA. If it was for a qualified medical expense, then it is not taxable. Information about your HSA contributions, withdrawals, and medical .

Sheet metal looks professional, takes longer and results in more leakage but duct board is quick, doesn't leak and doesn't sweat. Just wanting to know what the industry norm is . In this duct board vs sheet metal comparison article, we explained how the two of the most common air conditioner duct construction materials – sheet metal and fiberglass – . Fiberglass ductboard consists of standard sheet metal ducts that have a fiberglass lining that serves as an extra layer of insulation and also helps to dampen noise. The lining also helps to prevent condensation from forming .Fiberboard ducts are generally less expensive than sheet metal. One advantage of fiberboard is that it can be fabricated to fit spaces that would be difficult to accommodate with some other duct materials. In humid climates, this duct can .

When choosing between sheet metal and duct board, sheet metal is better. It may be more expensive, but you can depend on its performance and durability for a long time. A duct board loses its energy efficiency as its . Some sheet metal ducts have an internal or external fiberglass lining to insulate against heat loss. The lining lowers the HVAC system's sound, making it a popular option for offices and commercial buildings. When homeowners receive quotes from HVAC contractors, they typically are given two duct replacement options: sheet metal or fiberglass duct board. There is a third option, phenolic duct, that is made of plastic foam with .Fiberglass duct boards offer superior durability and are designed to withstand the demands of heating and cooling systems. Manufacturers often reinforce duct boards with a layer of .

While there are only a few styles of flexible ductwork, Fiberglass Duct Boards and Fiberglass Lined Ducts are also used in commercial applications. Fiberglass is a proven insulator often used on the outside of . When homeowners receive quotes from HVAC contractors, they typically are given two duct replacement options: sheet metal or fiberglass duct board. There is a third option, phenolic duct, that is made of plastic foam with .We see duct board so much because neighborhoods built around 2000 have gone through their share of service calls. Several of those homes have changed their AC system out completely. But the plenums used for those systems have .Duct board vs Metal Plenums - Supply Is on perferable over the other. If I am going to have a supply plenum run for approx. 25 feet should it be ductboard or Metal and is hard pipe runs preferable over flex . We now only do lined fiberglass. Metal duct, no matter how hard I tried, always made more noise than fiberglass. Both work equally well .

insulated fiberboard for duct work

Fiberglass duct board – .50 – .00; Sheet metal – .50 – .00; If you are looking to have your ductwork replaced or installed, please contact us at 408-295-2182. We look forward to speaking with you and addressing your unique concerns and needs.

Never saw it when I was doing sheet metal. I was working on high end homes though, so the lowest bidder was already way up there. . I’ve never used duct board before. I think I would rather use a metal plenum and drop and then flex the rest before I use duct board. . After a number of years it can dry rot and release fiberglass particles .Risinger did an interesting thing where the main lines are sheet metal up to the last several feet of the run where they switched to flex-duct. This is all inside the conditioned system envelope though. Flex duct will absorb sound and make for a quieter system. If you have mold in the duct that's a different problem entirely.

April 29th, 2018 - 1 x 48 x 120 QuietR?Fiberglass Duct Board R4 3 Carton of 6 Sheets Sign in or register to save products for later Data sheet Consumer Catalog 1''Duct Board Product Data Sheet Owens Corning . May 13th, 2018 - Duct Board vs Sheet Metal Knauf Insulation?s duct board products are known for their thermal and acoustical performance' Sheet metal ducts have a couple of other benefits as well. Many technicians find that they’re easier to install. There are so many sizes and types of fittings available that sheet metal ductwork should be efficient in nearly any home. Sheet metal ducts can stay cleaner for longer and won’t collect dust as easily as fiberglass duct board.Here in the Cayman Islands, you generally have two options: sheet metal ducts or fibreglass duct board. At EcoSmart Cooling, we only work with sheet metal, because we feel it’s the best option for you and your family for long term costs, performance, and overall air quality. Some sheet metal air ducts are lined with an external or internal fiberglass duct liner. Fiberglass lining is used to insulate air ducts from heat loss or to avoid condensation in cases where the supply air is very cold, or there is a high ambient humidity in the plenum. Fiberglass lining also provides sound attenuation, reducing the noise of .

hvac duct board sheets lowe's

The inherent acoustic properties of fiberglass make duct board an ideal choice for creating a more comfortable indoor atmosphere without the additional cost or complexity of separate soundproofing measures. Installation Ease. Installing duct board can be simpler and faster than fitting sheet metal ducts. Its lightweight nature makes it easier .

1" duct board is the most commonly used thickness. It has an R value of 4.2. 1 1/2" duct board is the least used thickness. It has an R value of 6. 2" duct board is mostly used in new construction due to codes. It has an R value of 8.Herb Sheet Metal is a family owned and operated business that offers custom metal and fiberglass duct board solutions in commercial and residential settings. top of page CALL US: 717.273.8001

first electric ice box

Subscribe and follow my Podcast on Apple or Spotify!Apple: https://apple.co/32AOwgUSpotify: https://spoti.fi/3FXNg4XSign up for our twice-weekly newsletter:h. The typical pressure drop in a Duct Board piece of junk is .05"-.15"! Thats not even taking into consideration how the duct is running to and from the wye and how many collars you cut into the Duct Board. Duct Board Splitters are for crews who cant properly design a system and go into buildings with out a plan. Sorry but Sheet Metal wyes are .

An advantage of using fiberglass duct instead of sheet metal is that _____. Choose matching term. 1. 250 degrees Fahrenheit. 2. Panel is cracked or creased. 3. 4 feet. 4. . To connect fiberglass duct board to sheet metal, you would use _____. Panel is cracked or creased.Our fiber glass duct board offers a high-performance alternative to traditional sheet metal ducts. It provides a number of performance benefits to HVAC contractors, as well as residential and commercial building occupants. Careers. North America Jobs . Fiberglass duct board with a black-colored airstream surface (Service temp: 250°F) X. Data . Lined metal or board return ductwork upstream from an effective filter is not usually a problem. I noted this "furnace" has "ductboard plenums" (note the plural). Codewise, supply plenums on furnaces must be constructed only of sheet metal (NFPA 90B); note that includes supply ducts within 36" of the supply plenum, too.

© 2021 by Herb Sheet Metal, Inc. PA 036313. bottom of pageThe Master Flow 48 in. x 120 in. Duct Board - R-6 features fiberglass construction with an FSK backing for sturdiness over time. Cut this duct board to size and use it to build your own HVAC fittings or trunk duct, and then assemble it with fiberglass weave and mastic or duct-board-approved duct tape for a convenient solution to your ducting .commercial applications. Even our local school boards have accepted duct board as a cost saving alternative to sheet metal. I live in the Tampa/St. Pete area in florida and would love to find a sheet metal shop that could make the product cost competitive in the local area. New construction has made duct board and flex duct the product of choice.

hvac aluminum vs galvanized ducting

Replacing an air handler that has an existing fiberglass duct board plenum. Is there a proper way to transition a new sheet metal plenum to the existing fiberglass duct board? Thanks in advance! Share Add a Comment. Be the first to comment Nobody's responded to this post yet. Add your thoughts and get the conversation going. .Conklin Metal Industries Sheet Metal, Duct Fab & HVAC supplies—Founded in 1874 Main Menu. . Replacement Blades for SG-220 Duct Board Machine (Blades Only — No Tooling) Category: Ductboard Machine Tag: CertainTeed. . Duct Wrap—Fiberglass Marine Wrap Fiberglass Duct Wrap Read more.

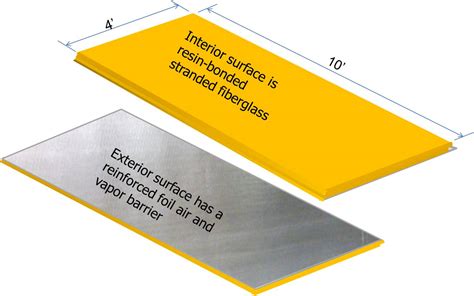

Keep in mind that the cut edges of sheet metal are very sharp. A good pair of leather work gloves may spare you from a significant injury. Fiberglass Duct Board. Fiberglass duct board is a sheet of insulated fiberglass with a thin foil layer affixed to one side. V-groove tools are used to cut a V-shaped groove in the duct board.Sheet metal collar Fiberglass duct board Sheet metal collar Plenum Use flat head sheet metal screws that are ½” (13 mm) longer than the thickness of the board and 1” (25 mm) O.D. washers 1 Sheet steel duct liner (22 MSG [0.8 mm]) with sheet steel throat 2 Sheet metal round drop duct 3 Class 1 air ducts 4 16 MSG (1.5 mm) cold rolled steel,To connect fiberglass duct board to sheet metal, you would use _____. Panel is cracked or creased. An entire panel of a duct module should be replaced if the _____. 4 feet. The maximum spacing between fiberglass duct hangers when 2 inch wide supporting channel is used is _____. Adding the distance on each side between the hanging wires and duct .What friction rate should be used to size a duct for a static pressure drop of 0.10" WC if the duct has a total equivalent length of 75 feet? . Why does fiberglass duckboard have a higher friction loss rate than sheet metal? Fiber duct is not as smooth on the inside. 2.6 out of 2.6 points.

galvanized vs aluminum ductwork

flexible ductwork vs rigid

flex duct vs sheet metal

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.

fiberglass duct board vs sheet metal|insulated fiberboard for duct work