cnc machine operator skills Mastery of technical skills including engineering knowledge, CAD/CAM software, and G-code programming is critical for CNC machinists to optimize manufacturing processes and address . Surface metal raceway allows you to add fixtures and outlets without disturbing the drywall, plaster or insulation in your home. It is also ideal for adding wire when you can't go into the wall, such as on concrete foundations or brick walls.

0 · skills for cnc machinist

1 · machinist skill levels explained

2 · cnc operator skills for resume

3 · cnc operator roles and responsibilities

4 · cnc machinist skills list

5 · cnc machine setup operator

6 · cnc machine operator job duties

7 · cnc job description and duties

They do make wiremold junction boxes that have knockouts for the wiremold itself but can also accept conduit connectors or mc connectors. If you cannot find one you can drill a 7/8" hole in the box where you want to connect the mc .

By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand .Learn how to highlight your CNC operator skills on your resume with examples and tips. Discover the most in-demand skills for CNC operators, such as CAD/CAM, G-code, Mastercam, and more.Mastery of technical skills including engineering knowledge, CAD/CAM software, and G-code programming is critical for CNC machinists to optimize manufacturing processes and address .CNC operators require advanced technical skills, strong attention to detail, and the ability to adhere to strict safety standards. CNC operators program, set up, and operate CNC machines, which use computer-aided design (CAD) and .

Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator.

Learn about the most important CNC Machine Operator skills, how you can utilize them in the workplace, and what to list on your resume. CNC machine operators are essential .

Understanding the role of a CNC machinist operator is key for anyone interested in the precision manufacturing sector. Responsible for both operating CNC machines and ensuring the . Computer Numerical Control (CNC) machining involves using technical equipment to automatically machine materials into products, parts or prototypes. It is a form of subtractive manufacturing that has become a .

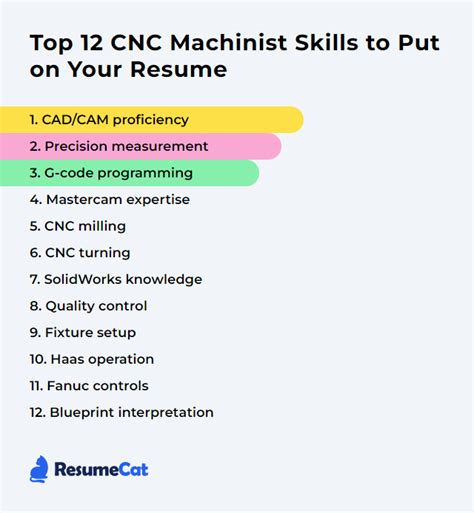

Learn about the most important CNC Operator skills, how you can utilize them in the workplace, and what to list on your resume. CNC operators are essential in manufacturing, . By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand the duties and responsibilities of a CNC machine operator.Boost your resume with these 12 essential CNC Operator skills, from precision machining to CAD/CAM proficiency, and stand out to employers.

What are CNC operator skills? CNC operator skills are divided into two integral categories: soft and hard skills. Hard skills refer to the specific technical knowledge and abilities required to perform your job, like understanding CNC programming or operating machinery.Mastery of technical skills including engineering knowledge, CAD/CAM software, and G-code programming is critical for CNC machinists to optimize manufacturing processes and address complex machining challenges.CNC operators require advanced technical skills, strong attention to detail, and the ability to adhere to strict safety standards. CNC operators program, set up, and operate CNC machines, which use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to cut, shape, and form various materials. Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator.

Learn about the most important CNC Machine Operator skills, how you can utilize them in the workplace, and what to list on your resume. CNC machine operators are essential in manufacturing, ensuring precision and efficiency. They operate complex machinery that shapes parts and components used across various industries.Understanding the role of a CNC machinist operator is key for anyone interested in the precision manufacturing sector. Responsible for both operating CNC machines and ensuring the production of high-quality parts, these operators are a pivotal part of the industry.

Computer Numerical Control (CNC) machining involves using technical equipment to automatically machine materials into products, parts or prototypes. It is a form of subtractive manufacturing that has become a popular method in making precision parts for the aerospace, automotive, power and other technical industries.

Learn about the most important CNC Operator skills, how you can utilize them in the workplace, and what to list on your resume. CNC operators are essential in manufacturing, ensuring precision and efficiency in machine operations that .

By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand the duties and responsibilities of a CNC machine operator.Boost your resume with these 12 essential CNC Operator skills, from precision machining to CAD/CAM proficiency, and stand out to employers.

what is the minimum sheet metal thickness

What are CNC operator skills? CNC operator skills are divided into two integral categories: soft and hard skills. Hard skills refer to the specific technical knowledge and abilities required to perform your job, like understanding CNC programming or operating machinery.Mastery of technical skills including engineering knowledge, CAD/CAM software, and G-code programming is critical for CNC machinists to optimize manufacturing processes and address complex machining challenges.

CNC operators require advanced technical skills, strong attention to detail, and the ability to adhere to strict safety standards. CNC operators program, set up, and operate CNC machines, which use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to cut, shape, and form various materials. Learn what skills your peers have and what skills you need to get ahead as a CNC Machinist or CNC Machine Operator. Learn about the most important CNC Machine Operator skills, how you can utilize them in the workplace, and what to list on your resume. CNC machine operators are essential in manufacturing, ensuring precision and efficiency. They operate complex machinery that shapes parts and components used across various industries.Understanding the role of a CNC machinist operator is key for anyone interested in the precision manufacturing sector. Responsible for both operating CNC machines and ensuring the production of high-quality parts, these operators are a pivotal part of the industry.

Computer Numerical Control (CNC) machining involves using technical equipment to automatically machine materials into products, parts or prototypes. It is a form of subtractive manufacturing that has become a popular method in making precision parts for the aerospace, automotive, power and other technical industries.

skills for cnc machinist

what is the definition of junction box

what is the purpose of a junction box

what is smart junction box

what is the metal thing in boxing

Inside the junction box, locate the terminals labeled “line” and “load” on the L5 30 receptacle. Connect the black wire (hot) to the brass terminal screw, the white wire (neutral) to the silver terminal screw, and the green or bare wire (ground) to the green terminal screw.

cnc machine operator skills|skills for cnc machinist